Egress Path Markings and Nosings

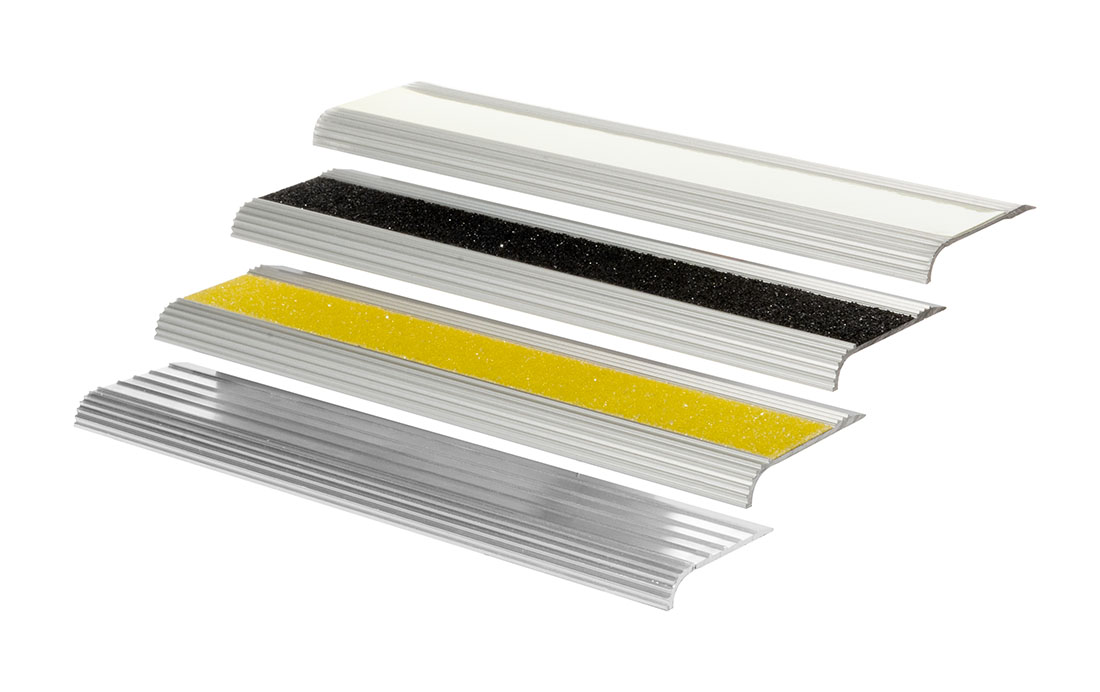

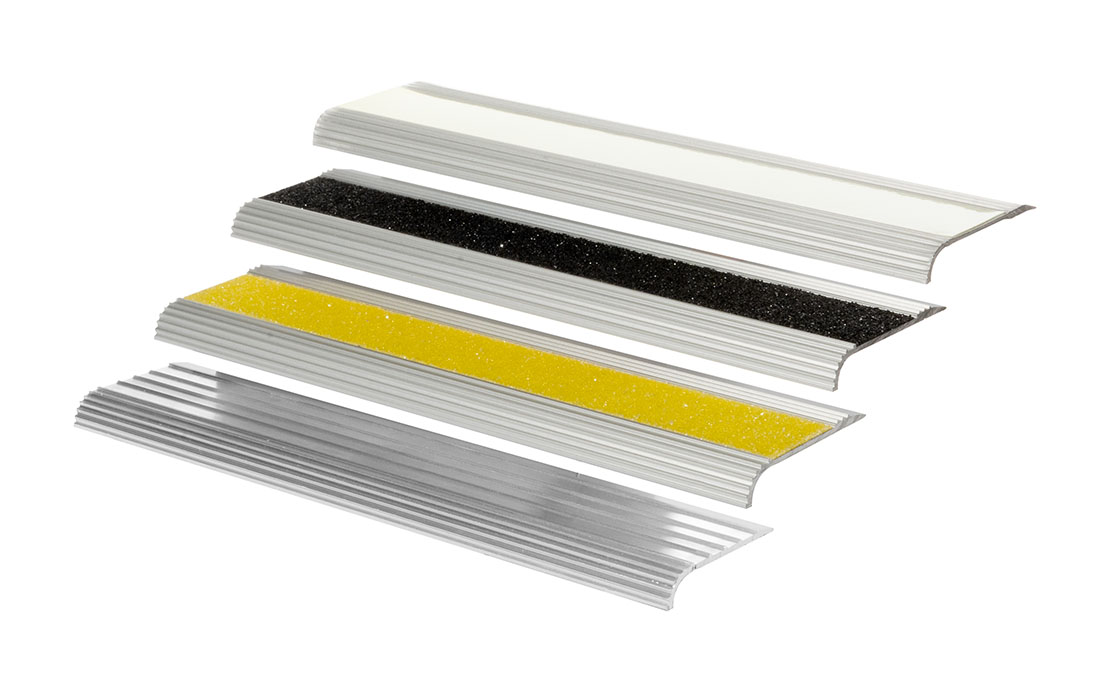

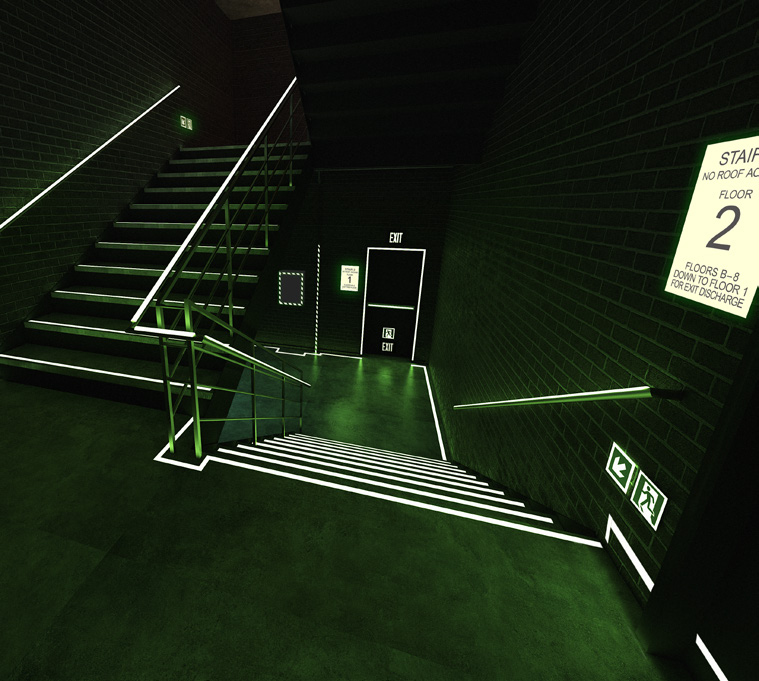

Photoluminescent or Abrasive, Contrasting Stripe Stair / Step Edge Nosing and Directional Signage

Photoluminescent, Abrasive, And Contrasting Stripe Stair Nosings And More.

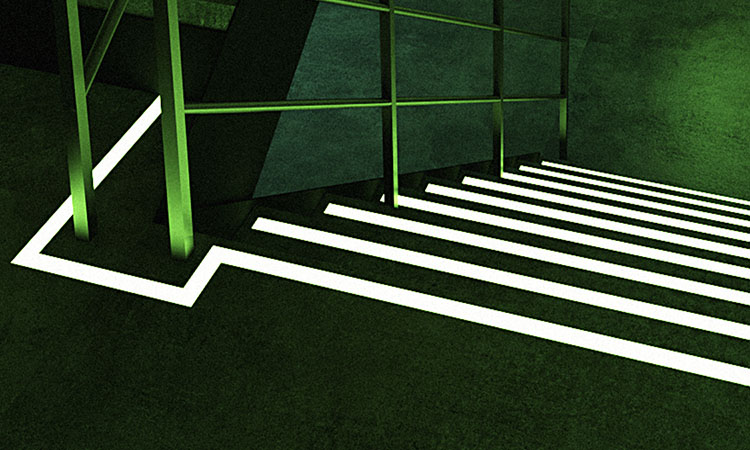

Our aluminum stair nosings have been meticulously designed to meet the specific requirements of our clients, addressing requirements such as contrasting stripes, abrasion, slip resistance, photoluminescence, and protection of the stair tread leading edge.

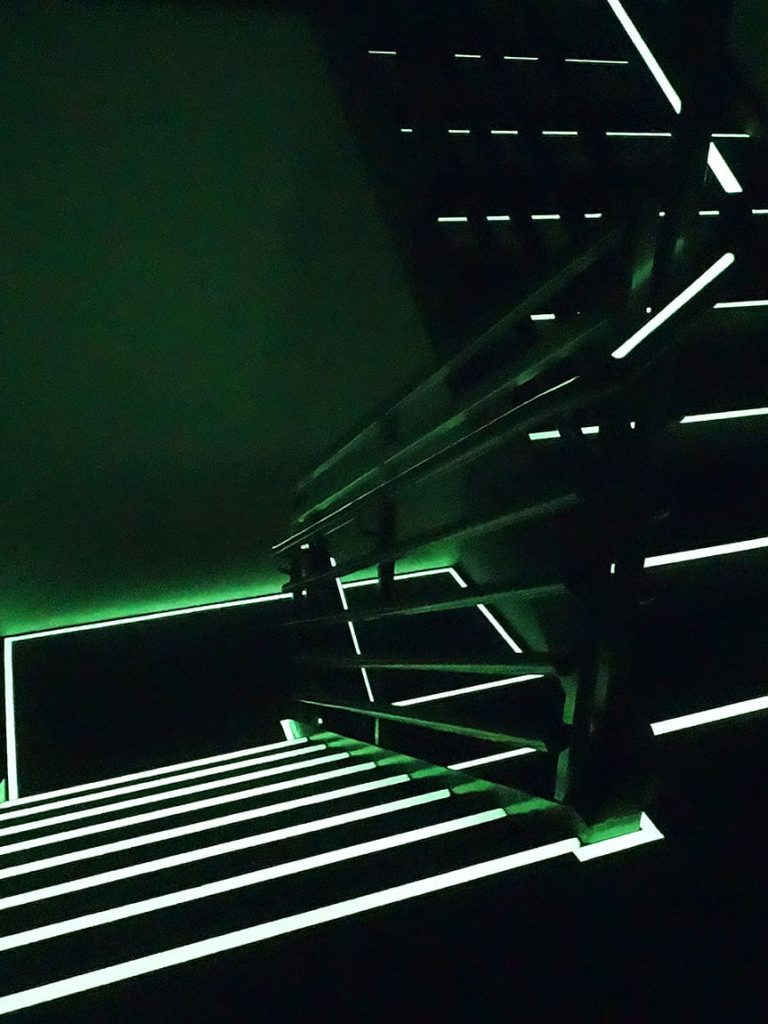

By combining our popular stair nosings with our comprehensive range of photoluminescent path markings and exit signs, we offer a complete solution for enhancing safety and aesthetics in any building or facility.

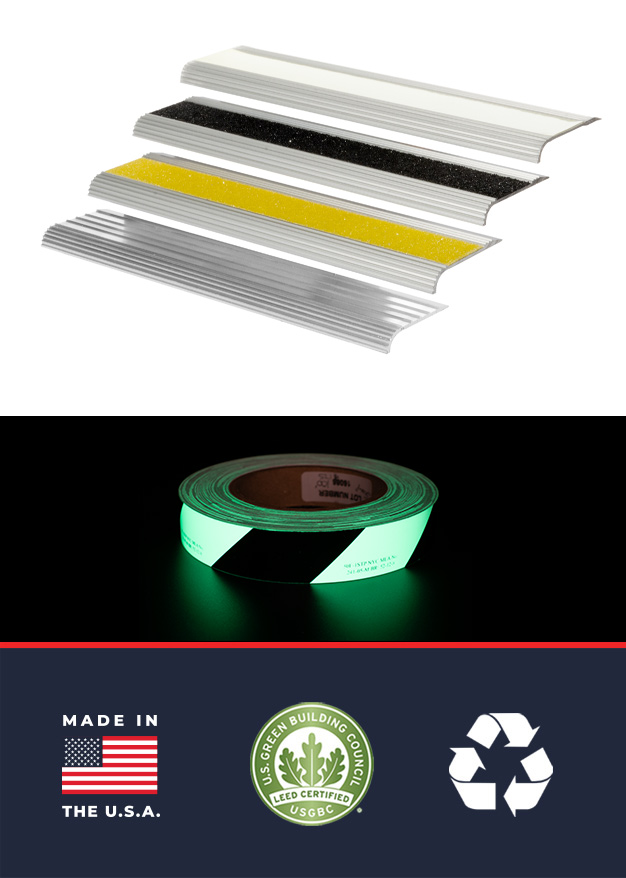

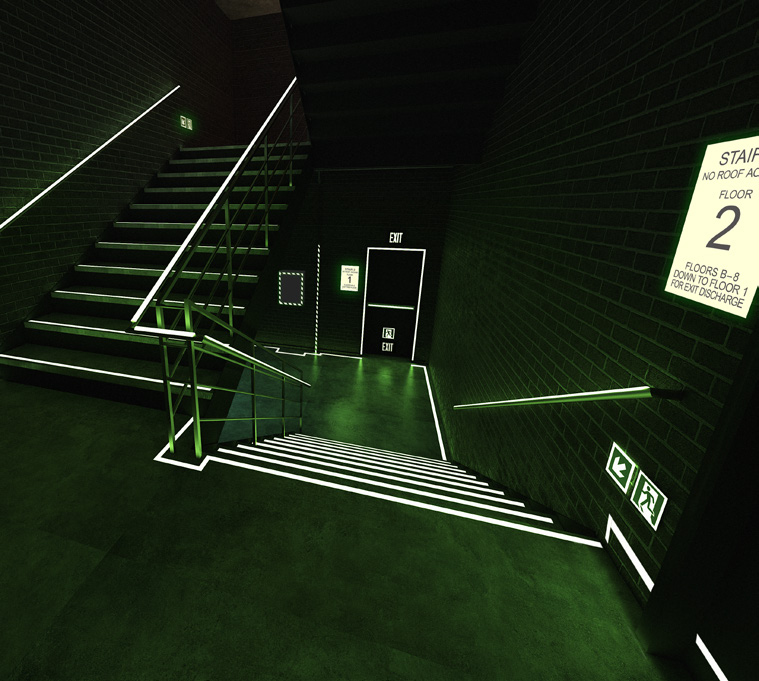

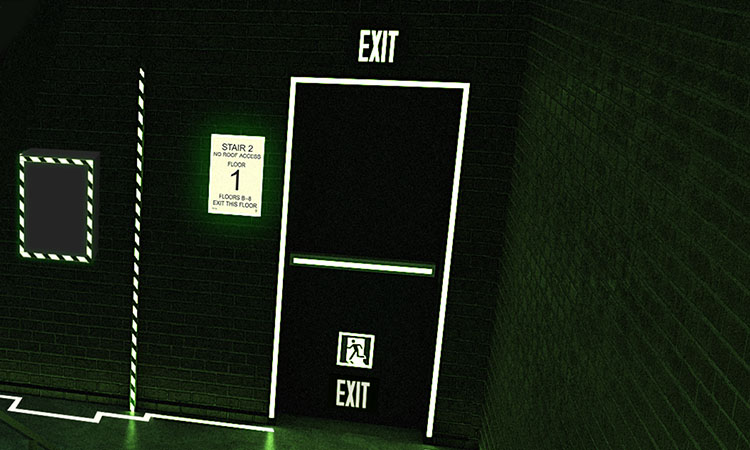

National Stair Products includes a wide range of photoluminescent path markings and exit signs. These markings and signs are designed to provide clear and visible guidance during emergencies, enhancing evacuation procedures and ensuring occupant safety.

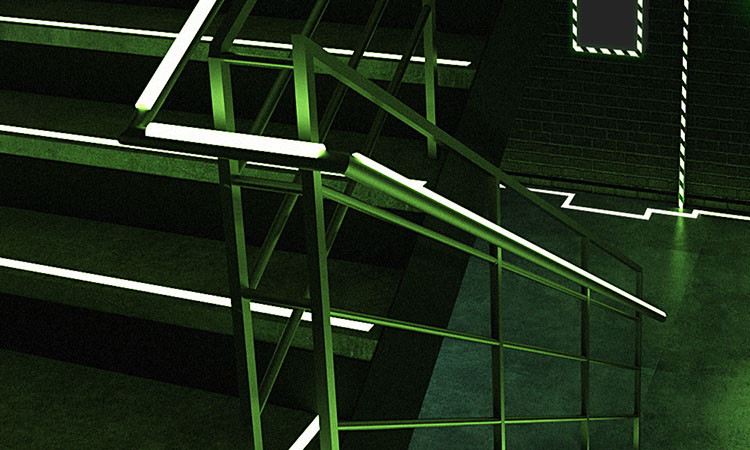

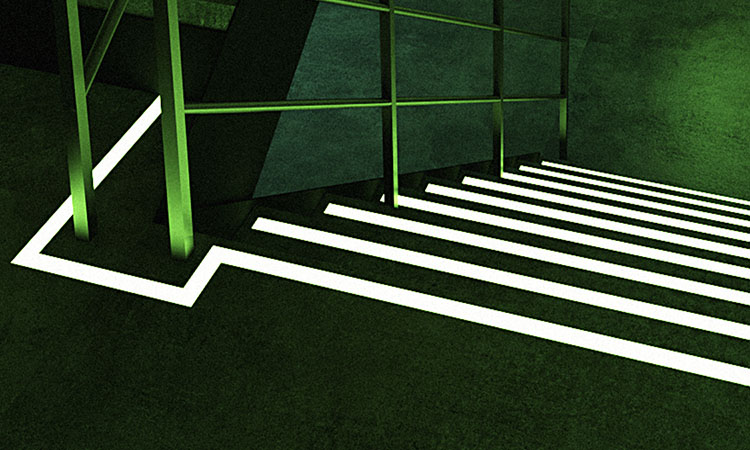

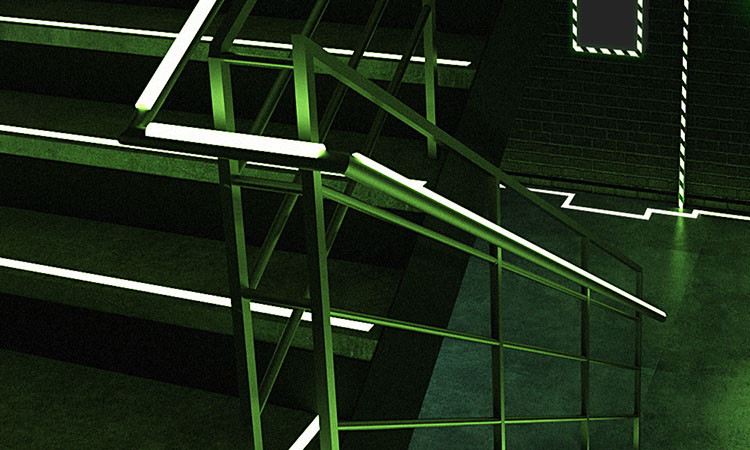

The photoluminescent path markings, such as handrail strips, floor markers, and obstacle tapes, are engineered to be highly visible and long-lasting, even in complete darkness. And our photoluminescent exit signs are available in various styles, including running man signs, final exit signs, and directional arrows.

Download:

- Complies with key safety codes (IBC, IFC, NFPA, UL 1994, UL 924, ASTM E2072, CAN/ULC-S572)

- Photoluminescent markings in stairwells and passageways for emergency evacuations

- Marks walkways to exits

- Visible in low-light/smoke conditions

- Marks handrails and obstructions

- Offers grades for high-traffic or low-use pathways

- Enhances building safety

Product Information:

Click headings below for more information.

Stair Nosings

Overview

Stair nosings for commercial, industrial, or residential building stair treads. Creating a photoluminescent / luminous path marking or abrasive contrasting strip for high visibility and non-slip. ADA, OSHA, IBC, IFC, NFPA, ASTM, UL compliant.

- Related Downloads:

- Egress Path Markings – Stair Nosing Product List

Stair Nosings

PHOTOLUMINESCENT / NON-SLIP / ABRASIVE / CONTRASTING STRIP

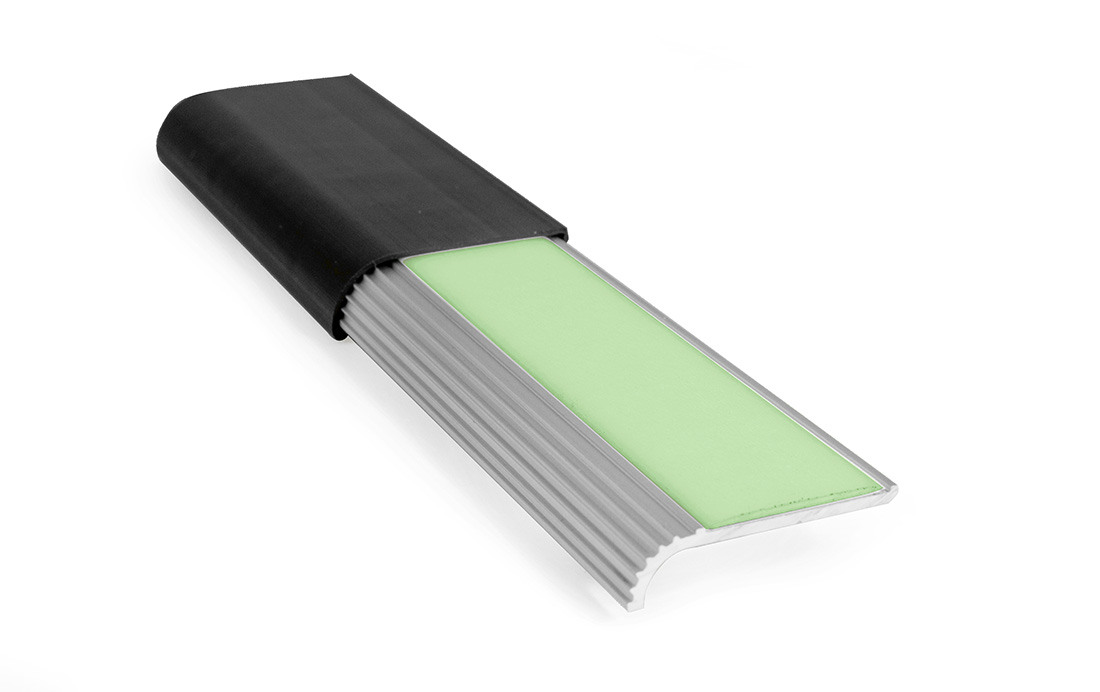

| Retrofit / Surface Mount 2” Stair Nosing | Model # | Description |

|---|---|---|

|

STNR | Low profile, 2” wide extruded aluminum nosing with beveled edge for smooth transition to tread finish, for retrofit and surface mount applications.

|

Key Product Information

- Typical Applications: Stair steps and landing edges. Concrete, Precast, Metal, Diamond Plate, Stone, Tile, Wood, Composites, Rubber, Carpet Treads

- Building Types: Commercial, Industrial, Residential, High Rise Buildings, Hospitals, Stadiums, Schools, Hotels, Multi-Use, Multi-Family, Apartment Buildings

- Supplied: Cut to Specified Length

Max Length: 12’-0” Long - Extruded Aluminum: Alloy 6063-T5

- Warranty: Up to 25 Years. Contact Safe-T-Nose for product warranty.

- Lifecycle: Up to 30 years with proper install and maintenance.

- Compliance: ASTM E2072 / UL 1994 / UL 410 / IBC / IFC / NFPA 101 / NFPA 170 / OSHA / ADA

- Stair Nosing – STNR – Product One Sheet

- Stair Nosing – STNR – Order Sheet

| Shop Applied 2” Stair Nosing | Model # | Description |

|---|---|---|

|

STNRS | Low profile, 2” wide extruded aluminum nosing with peel and stick adhesive and protective construction cover included. Installed on metal stair treads during fabrication.

|

Key Product Information

- Typical Applications: Stair steps and landing edges. Concrete Filled Stairs, Diamond Plate Stairs

- Building Types: Commercial, Industrial, Residential, High Rise Buildings, Hospitals, Stadiums, Schools, Hotels, Multi-Use, Multi-Family, Apartment Buildings

- Supplied: Cut to Specified Length

- Max Length: 12’-0” Long

- Extruded Aluminum: Alloy 6063-T5

- Construction Cover: Protects nosing during stair fabrication, shop paint, construction phase, finish paint, easily removed and recycled just before building occupancy.

- Warranty: Up to 25 Years. Contact Safe-T-Nose for product warranty.

- Lifecycle: Up to 30 years with proper install and maintenance.

- Compliance: ASTM E2072 / UL 1994 / UL 410 / IBC / IFC / NFPA 101 / NFPA 170 / OSHA / ADA

- Stair Nosing – STNRS – Product One Sheet

- Stair Nosing – STNRS – Order Sheet

| Shop Applied 1.5” Stair Nosing | Model # | Description |

|---|---|---|

|

STNS | Low profile, 1.5” wide extruded aluminum nosing with peel and stick backing with protective construction cover for shop apply to metal stair systems during fabrication.

|

Key Product Information

- Typical Applications: Stair steps and landing edges. Concrete, Precast, Metal, Diamond Plate, Stone, Tile, Wood, Composites, Carpet Treads

- Building Types: Commercial, Industrial, Residential, High Rise Buildings, Hospitals, Stadiums, Schools, Hotels, Multi-Use, Multi-Family, Apartment Buildings

- Supplied: Cut to Specified Length

- Max Length: 12’-0” Long

- Extruded Aluminum: Alloy 6063-T5

- Construction Cover: Protects nosing during stair fabrication, shop paint, construction phase, finish paint, easily removed and recycled just before building occupancy.

- Warranty: Up to 25 Years. Contact Safe-T-Nose for product warranty.

- Lifecycle: Up to 30 years with proper install and maintenance.

- Compliance: ASTM E2072 / UL 1994 / UL 410 / IBC / IFC / NFPA 101 / NFPA 170 / OSHA / ADA

- Stair Nosing – STNS – Product One Sheet

- Stair Nosing – STNS – Order Sheet

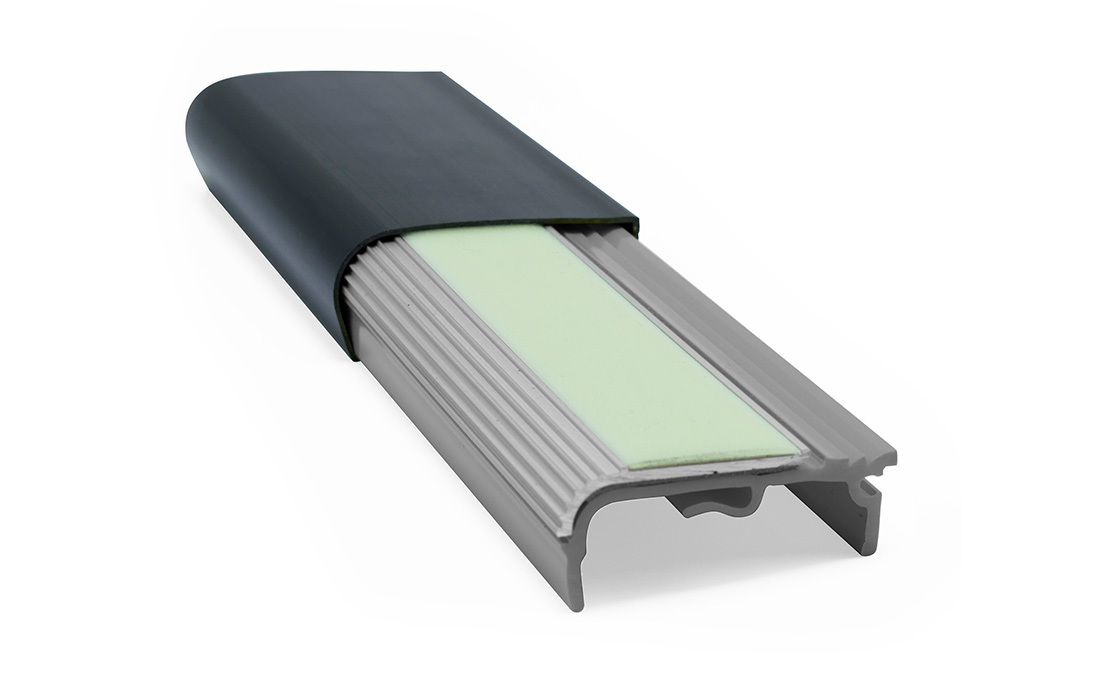

| Pan Filled Stair Tread 2” Clip-On Stair Nosing | Model # | Description |

|---|---|---|

|

STNP | Low profile, 2” wide nosing with clip-on assembly and protective construction cover included. Clips on to the metal pan lip before concrete pour.

|

Key Product Information

- Typical Applications: Designed for concrete filled stairs, 14-10 ga metal pans.

- Building Types: Commercial, Industrial, Residential, High Rise Buildings, Hospitals, Stadiums, Schools, Hotels, Multi-Use, Multi-Family, Apartment Buildings

- Supplied: Cut to Specified Length

- Max Length: 12’-0” Long

- Extruded Aluminum: Alloy 6063-T5

- Construction Cover: Protects nosing during stair fabrication, shop paint, construction phase, finish paint, easily removed and recycled just before building occupancy.

- Warranty: Up to 25 Years. Contact Safe-T-Nose for product warranty.

- Lifecycle: Up to 30 years with proper install.

- Compliance: ASTM E2072 / UL 1994 / UL 410 / IBC / IFC / NFPA 101 / NFPA 170 / OSHA / ADA

- Stair Nosing – STNP – Product One Sheet

- Stair Nosing – STNP – Order Sheet

| Cast-In-Place Stair 2” Embed Stair Nosing | Model # | Description |

|---|---|---|

|

STNC | Low profile, 2” wide nosing assembly with protective construction cover. Embedded into wet concrete.

|

Key Product Information

- Typical Applications: Designed for Cast-In-Place stairs and precast concrete treads.

- Building Types: Commercial, Industrial, Residential, High Rise Buildings, Hospitals, Stadiums, Schools, Hotels, Multi-Use, Multi-Family, Apartment Buildings

- Supplied: Cut to Specified Length

- Max Length: 12’-0” Long

- Extruded Aluminum: Alloy 6063-T5

- Extruded Aluminum Finish Options: Mill Finish, Clear Anodized, Yellow Powder Coat, Black Powder Coat

- Construction Cover: Protects nosing during stair fabrication, shop paint, construction phase, finish paint, easily removed and recycled just before building occupancy.

- Warranty: Up to 25 Years. Contact Safe-T-Nose for product warranty.

- Lifecycle: Up to 30 years with proper install and maintenance.

- Compliance: ASTM E2072 / UL 1994 / UL 410 / IBC / IFC / NFPA 101 / NFPA 170 / OSHA / ADA

- Stair Nosing – STNC – Product One Sheet

- Stair Nosing – STNC – Order Sheet

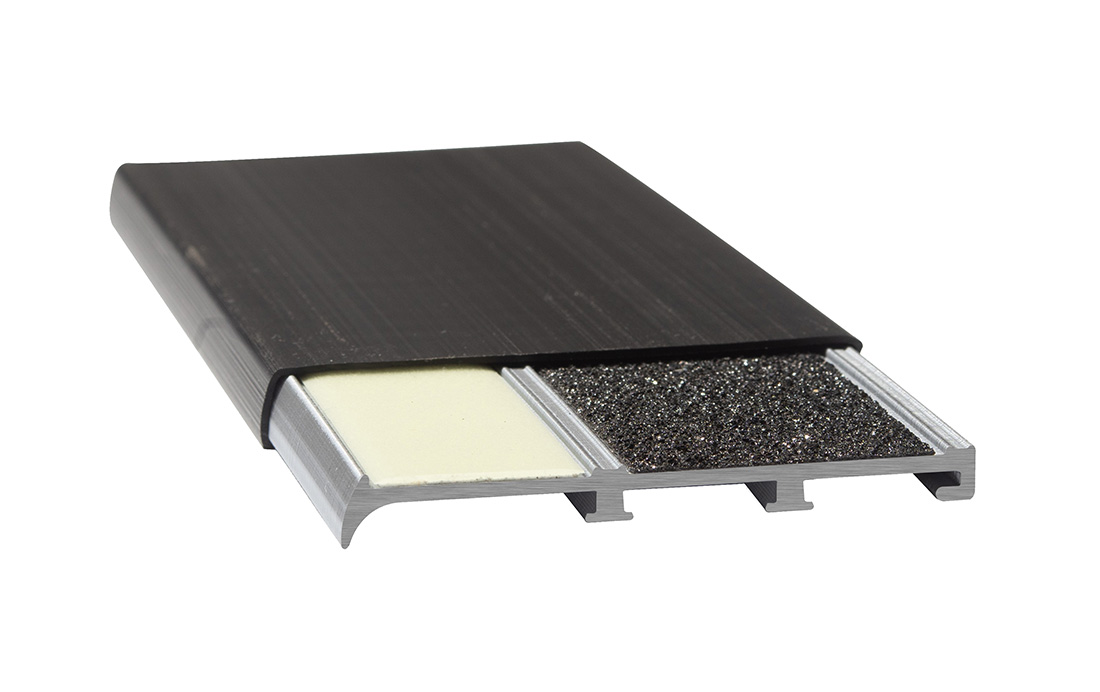

| Cast-In-Place Stair 3” Stair Nosing | Model # | Description |

|---|---|---|

|

STNC3 | Low profile, 3” wide aluminum nosing with protective construction cover. Embedded into wet concrete.

|

Key Product Information

- Typical Applications: Designed for Cast-In-Place stairs, precast concrete treads, pan filled stairs.

- Building Types: Commercial, Industrial, Residential, High Rise Buildings, Hospitals, Stadiums, Schools, Hotels, Multi-Use, Multi-Family, Apartment Buildings

- Supplied: Cut to Specified Length

- Max Length: 12’-0” Long

- Extruded Aluminum: Alloy 6063-T5

- Extruded Aluminum Finish Options: Mill Finish, Clear Anodized, Yellow Powder Coat, Black Powder Coat

- 1” Glow Strip Options: Extruded Resin Strip or Acrylic Vinyl Strip

- 1” and 1.5” Abrasive Contrast Only Strip Options: Traction Yellow or Traction Black

- Attachment Options: Concrete contractor inserts into wet concrete during pour.

- Construction Cover: Protects nosing during concrete pour, construction phase and easily removed/recycled just before building occupancy.

- Warranty: Up to 25 Years. Contact Safe-T-Nose for product warranty.

- Lifecycle: Up to 30 years with proper install.

- Compliance: ASTM E2072 / UL 1994 / UL 410 / IBC / IFC / NFPA 101 / NFPA 170 / OSHA / ADA

- Stair Nosing – STNC3 – Product One Sheet

- Stair Nosing – STNC3 – Order Sheet

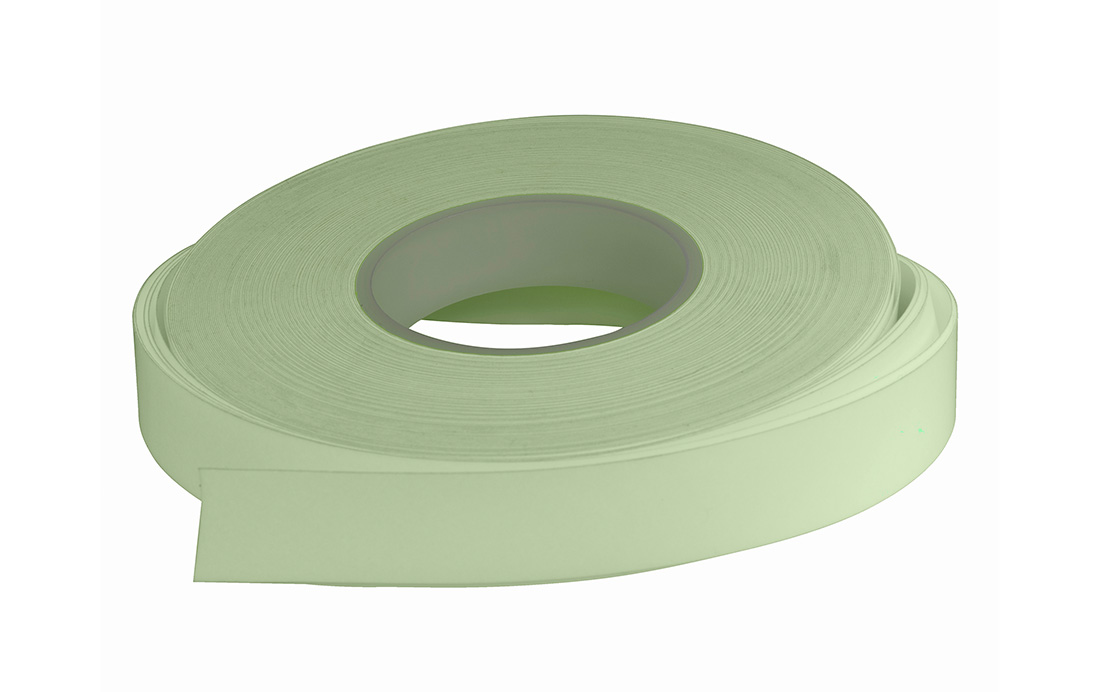

| 1” Photoluminescent Extruded Polymer Resin strip Stair Nose Marking | Model # | Description |

|---|---|---|

|

STNF(N) | Budget compliance, low to moderate use, interior applications. Low profile, 1” wide extruded polymer resin photoluminescent nosing tape with peel and stick foam adhesive.

|

Key Product Information

- Typical Applications: Designed for surface mount to smooth/flat surfaces only. Cast-In-Place Stair Treads, Precast Concrete Stair Treads, Pan Filled Stairs, Checker Plate Stairs, Metal, Concrete, Stone, Tile, Wood, Vinyl, Rubber, Painted Surfaces

- Building Types: Commercial, Industrial, Residential, High Rise Buildings, Hospitals, Stadiums, Schools, Hotels, Multi-Use, Multi-Family, Apartment Buildings

- Supplied: 100 LF Rolls, cut with scissors.

- Assembly: Extruded photoluminescent polymer resin with premium peel and stick foam tape backing.

- Attachment Options: Peel and stick to smooth/flat surfaces only. Verify surfaces are suitable.

- Warranty: Up to 25 Years. Contact Safe-T-Nose for product warranty.

- Lifecycle: Up to 30 years with proper install and maintenance.

- Compliance: ASTM E2072 / UL 1994 / IBC / IFC / NFPA 101 / NFPA 170

- Stair Nosing – STNF(N) – Product One Sheet

Handrail Markings

Overview

Handrail markings for commercial, industrial, or residential buildings. Creates photoluminescent / luminous wayfinding with high visibility contrast and illuminated during no-light, low-light conditions, or during emergencies. Directs occupants to the final exit. Outlines stair rails and egress direction for safety. IBC, IFC, NFPA, ASTM, UL compliant.

- Related Downloads:

- Egress Path Markings – Handrail Marking Product List

Handrail Markings

PHOTOLUMINESCENT / LUMINOUS HANDRAIL MARKINGS

| Handrail Marking Strip – 1” Wide Curved Photoluminescent Extruded Polymer Resin | Model # | Description |

|---|---|---|

|

STNH | Commercial grade, high use, interior applications. Pre-curved to grab round handrail only. Low profile, 1” wide curved extruded polymer resin photoluminescent stripe with peel and stick foam adhesive.

|

Key Product Information

- Typical Applications: Designed for surface mount to finished round handrail surfaces, interior applications: painted, galvanized, metal, stainless steel, wood.

- Building Types: Commercial, Industrial, Residential, High Rise Buildings, Hospitals, Stadiums, Schools, Hotels, Multi-Use, Multi-Family, Apartment Buildings

- Supplied: 10 LF Sticks, cut with scissors.

- Assembly: Curved extruded photoluminescent polymer resin with premium peel and stick foam tape.

- Attachment Options: Peel and stick to smooth/round handrail surfaces only – 1.5” (1.66” O.D.) Round Pipe Surfaces. Verify surfaces are suitable.

- Warranty: 25 year glow warranty. Contact Safe-T-Nose for product warranty.

- Lifecycle: Up to 30 years with proper install and maintenance.

- Compliance: ASTM E2072 / UL 1994 / IBC / IFC / NFPA 101 / NFPA 170

- Handrail Markings – STNH – Product One Sheet

| Handrail Marking Tape – 1” Wide Photoluminescent Acrylic Vinyl | Model # | Description |

|---|---|---|

|

S9203(H) | Budget compliance, low to moderate use, interior applications. 1” wide acrylic vinyl photoluminescent tape with peel and stick adhesive.

|

Key Product Information

- Typical Applications: Designed for surface mount to finished round handrail surfaces, interior applications: painted, galvanized, metal, stainless steel, wood.

- Building Types: Commercial, Industrial, Residential, High Rise Buildings, Hospitals, Stadiums, Schools, Hotels, Multi-Use, Multi-Family, Apartment Buildings

- Supplied: 150 LF Rolls, cut with scissors.

- Assembly: Acrylic vinyl photoluminescent tape with peel and stick backing.

- Attachment Options: Peel and stick to smooth/flat or round handrail surfaces. Verify surfaces are suitable.

- Warranty: 5 year glow warranty. Contact Safe-T-Nose for product warranty.

- Lifecycle: Up to 10 years with proper install and maintenance.

- Compliance: ASTM E2072 / UL 1994 / IBC / IFC / NFPA 101 / NFPA 170

- Handrail Markings – S9203(H) – Product One Sheet

Perimeter Markings

Overview

Perimeter and obstruction path markings for commercial, industrial, or residential buildings. Creates photoluminescent / luminous wayfinding with high visibility contrast and illuminated during no-light, low-light conditions, or during emergencies. Directs occupants to the final exit. Outlines obstructions and hazards. IBC, IFC, NFPA, ASTM, UL compliant.

- Related Downloads:

- Egress Path Markings – Perimeter Marking Product List

Perimeter Markings

PHOTOLUMINESCENT / WALKWAYS / CORRIDORS / VESTIBULES / LANDINGS / DOOR FRAMES / PERIMETERS / OBSTRUCTIONS

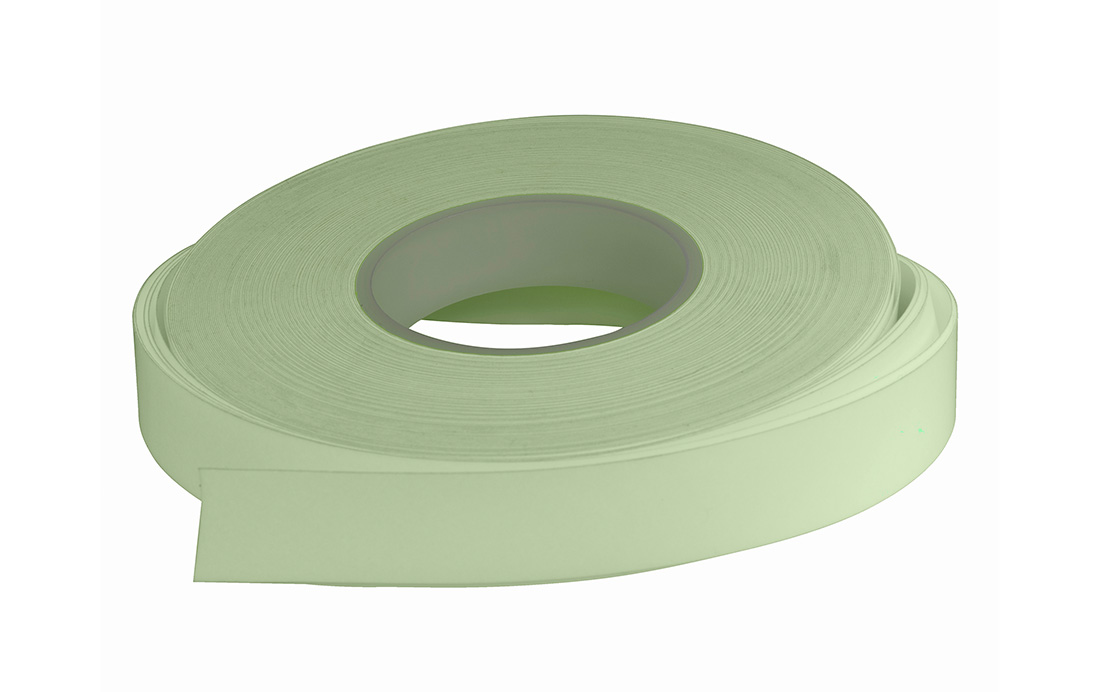

| Perimeter Marking Strip – 1” Wide Photoluminescent Extruded Polymer Resin | Model # | Description |

|---|---|---|

|

STNF | Commercial grade, high use, interior applications. Low profile, 1” wide extruded polymer resin photoluminescent perimeter marking stripe with peel and stick foam adhesive.

|

Key Product Information

- Typical Applications: Designed for surface mount to smooth/flat surfaces only. Floors, Walls, Doors, Frames, Steel, Concrete, Stone, Tile, Wood, Vinyl, Rubber, Painted Surfaces

- Building Types: Commercial, Industrial, Residential, High Rise Buildings, Hospitals, Stadiums, Schools, Hotels, Multi-Use, Multi-Family, Apartment Buildings

- Supplied: 100 LF Rolls, cut with scissors.

- Assembly: Extruded photoluminescent polymer resin with premium peel and stick foam tape backing. Abrasion and scratch resistance, tear resistance.

- Attachment Options: Peel and stick to smooth/flat surfaces only. Verify surfaces are suitable.

- Warranty: 25 year glow warranty. Contact Safe-T-Nose for product warranty.

- Lifecycle: Up to 30 years with proper install and maintenance.

- Compliance: ASTM E2072 / UL 1994 / IBC / IFC / NFPA 101 / NFPA 170

- Perimeter Markings – STNF – Product One Sheet

| Perimeter Marking Tape – 1” Wide Photoluminescent Acrylic Vinyl | Model # | Description |

|---|---|---|

|

S9203(F) | Budget compliance, low to moderate use, interior applications. 1” wide acrylic vinyl photoluminescent tape with peel and stick adhesive.

|

Key Product Information

- Typical Applications: Designed for surface mount to smooth/flat or round surfaces. Floors, walls, door frames, steel, concrete, vinyl, painted surfaces.

- Building Types: Commercial, Industrial, Residential, High Rise Buildings, Hospitals, Stadiums, Schools, Hotels, Multi-Use, Multi-Family, Apartment Buildings

- Supplied: 150 LF Rolls, cut with scissors.

- Assembly: Acrylic vinyl photoluminescent tape with peel and stick backing.

- Attachment Options: Peel and stick to smooth/flat or round surfaces. Verify surfaces are suitable.

- Warranty: 5 year glow warranty. Contact Safe-T-Nose for product warranty.

- Lifecycle: Up to 10 years with proper install and maintenance.

- Compliance: ASTM E2072 / UL 1994 / IBC / IFC / NFPA 101 / NFPA 170

- Perimeter Markings – S9203(F) – Product One Sheet

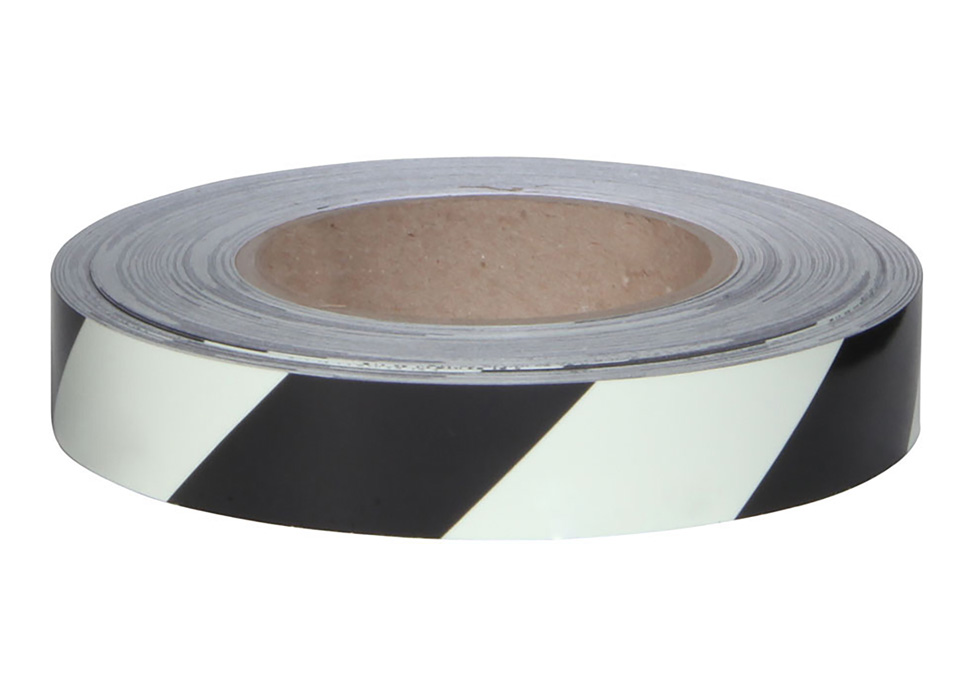

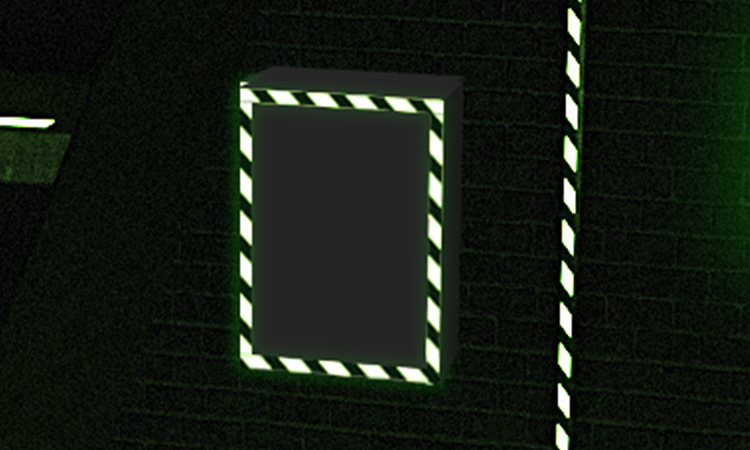

| Obstruction Marking Tape – 1” Wide Photoluminescent / Black Stripe Acrylic Vinyl | Model # | Description |

|---|---|---|

|

O150 | Hazard marking, interior applications. 1” wide acrylic vinyl obstruction marking tape with peel and stick adhesive.

|

Key Product Information

- Typical Applications: Hazard marking, interior applications. Designed for surface mount to smooth/flat or round surfaces. Obstructions impeding egress path, steel, concrete, painted surfaces. Verify surfaces are suitable.

- Building Types: Commercial, Industrial, Residential, High Rise Buildings, Hospitals, Stadiums, Schools, Hotels, Multi-Use, Multi-Family, Apartment Buildings

- Supplied: 150 LF Rolls, cut with scissors.

- Assembly: Acrylic vinyl photoluminescent tape with hazard photoluminescent and black striping, with peel and stick backing.

- Attachment Options: Peel and stick to smooth/flat or round surfaces. Verify surfaces are suitable.

- Warranty: 5 year glow warranty. Contact Safe-T-Nose for product warranty.

- Lifecycle: Up to 10 years with proper install and maintenance.

- Compliance: ASTM E2072 / UL 1994 / IBC / IFC / NFPA 101 / NFPA 170

- Obstruction Markings – O150 – Product One Sheet

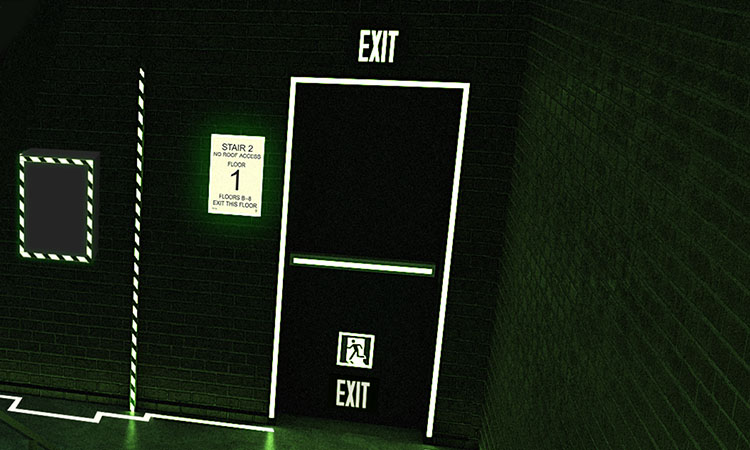

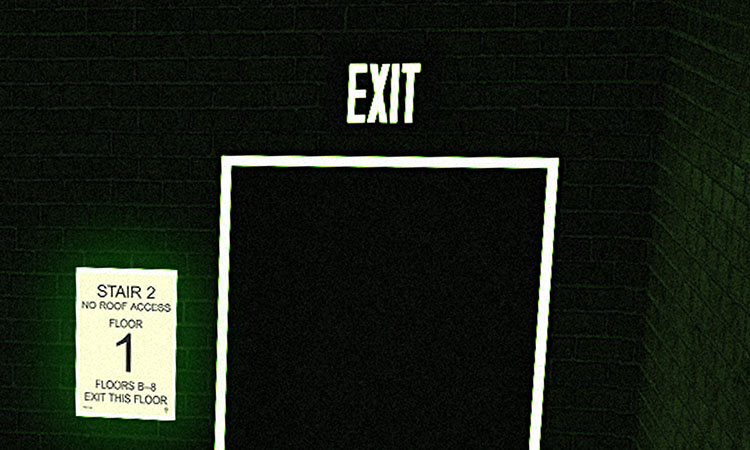

Exit Signs

Overview

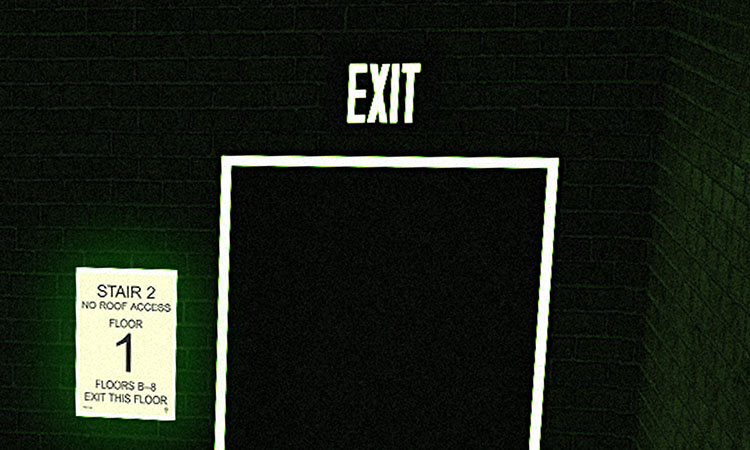

Stairwell photoluminescent egress path marking signs for commercial, industrial, or residential buildings. Creates photoluminescent / luminous wayfinding with high visibility contrast and illuminated during no-light, low-light conditions, or during emergencies. Directs occupants to the final exit. The complete code required exit signs that require no electricity wiring or battery backup. IBC, IFC, NFPA, ASTM, UL compliant.

- Related Downloads:

- Egress Path Markings – Handrail Marking Product List

PHOTOLUMINESCENT / LUMINOUS EGRESS EXIT SIGNS

Stair Identification Signs / Directional Signs / Running Man Signs / Final Exit Signs / Low Level Exit Signs / No Exit Signs / Combination Signs / Evacuation Path Signs / Door Latch Signs / Non-Glow Egress Signs / Custom Egress Signs

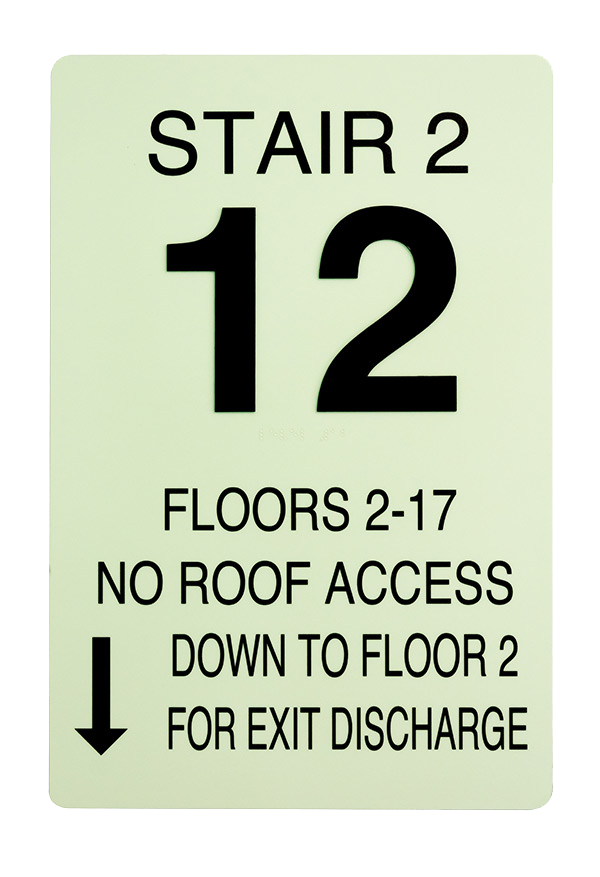

| Stairwell Identification Sign | Model # | Description |

|---|---|---|

|

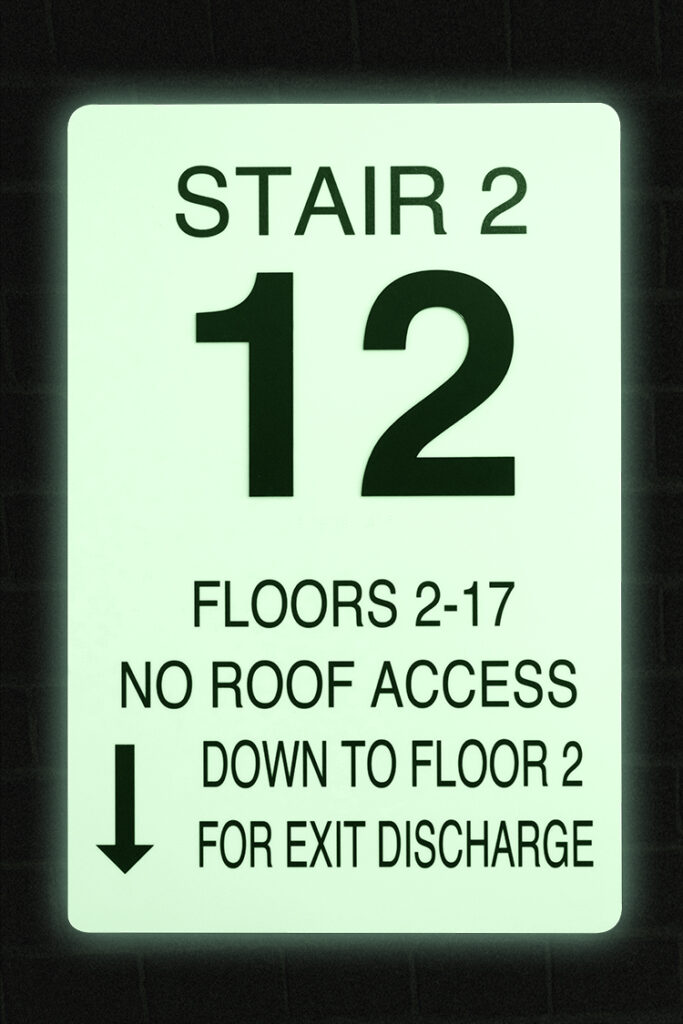

ISID | Photoluminescent custom made stairwell identification sign. Placed at each floor level in exit stair enclosures to direct occupants to final exit discharge.

|

Key Product Information

- Typical Applications: Installed inside stairwell at each floor level, 60” above floor landing located next to doorway opening. Designed to be clearly visible and understandable in emergencies and under all lighting conditions.

- Building Types: Commercial, Industrial, Residential, High Rise Buildings, Hospitals, Stadiums, Schools, Hotels, Multi-Use, Multi-Family, Apartment Buildings

- Supplied: 18” tall x 12” wide minimum, custom designed.

- Background Options: Photoluminescent Acrylic (Standard), Non-Photoluminescent – contact Safe-T-Nose for options.

- Rigid Backing Options: White ⅛” PVC Board (Standard), contact Safe-T-Nose for options.

- Attachment Options: Liquid adhesive, peel and stick backing included.

- Warranty: Up to 25 Years. Contact Safe-T-Nose for product warranty.

- Lifecycle: Up to 30 years with proper install and maintenance.

- Compliance: ASTM E2072 / UL 1994 / IBC / IFC / NFPA 101 / NFPA 170 / ICC A117.1

- Performance: A charging source of 1 ft-candle (11 lux) fo fluorescent or natural light illumination is necessary for 60 minutes to ensure that minimum luminance requirements of 30 mcd/m2 at 10 minutes and 5 mcd/m2 at 90 minutes are met after failure of the main lighting.

The sign must provide:

- Required at every floor level in the exit stairwell.

- Minimum 18″ x 12″ photoluminescent background.

- Identification of the stair or ramp – minimum 1 ½” in height.

- The floor level – raised and a minimum of 5” in height.

- Other lettering and numbers shall not exceed 1” in height.

- Braille floor identifier to comply with ICC A117.1.

- Terminus of the top and bottom of the exit enclosure.

- Availability of roof access from the enclosure.

- Story of and direction to the exit discharge.

- Final exit level ID sign to include star to designate the exit level.

- Stairwell Identification Sign – ISID – Product One Sheet

| Diagonal Arrow Directional Sign | Model # | Description |

|---|---|---|

|

DAD | Photoluminescent diagonal arrow “Pictogram” sign. Directs occupants down or up the egress path to the final exit door.

|

Key Product Information

- Typical Applications: Placed at each floor landing to first step transition in exit stair enclosures to direct occupants up or down stairwell to final exit discharge. Designed to be clearly visible and understandable in emergencies and under all lighting conditions.

- Building Types: Commercial, Industrial, Residential, High Rise Buildings, Hospitals, Stadiums, Schools, Hotels, Multi-Use, Multi-Family, Apartment Buildings

- Supplied: 5” tall x 5” wide.

- Background Options: Photoluminescent Acrylic (Standard), Non-Photoluminescent – contact Safe-T-Nose for options.

- Backing Options: Acrylic Film (Standard) White ⅛” PVC Rigid Board Backing (Upgrade), contact Safe-T-Nose for options.

- Attachment Options: Peel and stick backing included.

- Warranty: Up to 25 Years. Contact Safe-T-Nose for product warranty.

- Lifecycle: Up to 30 years with proper install and maintenance.

- Compliance: ASTM E2072 / UL 1994 / IBC / IFC / NFPA 101 / NFPA 170 / ICC A117.1

- Performance: A charging source of 1 ft-candle (11 lux) of fluorescent or natural light illumination is necessary for 60 minutes to ensure that minimum luminance requirements of 30 mcd/m2 at 10 minutes and 5 mcd/m2 at 90 minutes are met after failure of the main lighting.

- Diagonal Arrow Directional Sign – DAD – Product One Sheet

| Straight Arrow Directional Sign | Model # | Description |

|---|---|---|

|

DAS | Photoluminescent straight arrow “Pictogram” sign. Directs occupants to the left or right of the egress path to the final exit door.

|

Key Product Information

- Typical Applications: Placed at each floor landing in exit stair enclosures and around corners in corridors to direct occupants left or right to final exit discharge. Designed to be clearly visible and understandable in emergencies and under all lighting conditions.

- Building Types: Commercial, Industrial, Residential, High Rise Buildings, Hospitals, Stadiums, Schools, Hotels, Multi-Use, Multi-Family, Apartment Buildings

- Supplied: 5” tall x 5” wide.

- Background Options: Photoluminescent Acrylic (Standard), Non-Photoluminescent – contact Safe-T-Nose for options.

- Backing Options: Acrylic Film (Standard) White ⅛” PVC Rigid Board Backing (Upgrade), contact Safe-T-Nose for options.

- Attachment Options: Peel and stick backing included.

- Warranty: Up to 25 Years. Contact Safe-T-Nose for product warranty.

- Lifecycle: Up to 30 years with proper install and maintenance.

- Compliance: ASTM E2072 / UL 1994 / IBC / IFC / NFPA 101 / NFPA 170 / ICC A117.1

- Performance: A charging source of 1 ft-candle (11 lux) of fluorescent or natural light illumination is necessary for 60 minutes to ensure that minimum luminance requirements of 30 mcd/m2 at 10 minutes and 5 mcd/m2 at 90 minutes are met after failure of the main lighting.

- Straight Arrow Directional Sign – DAS – Product One Sheet

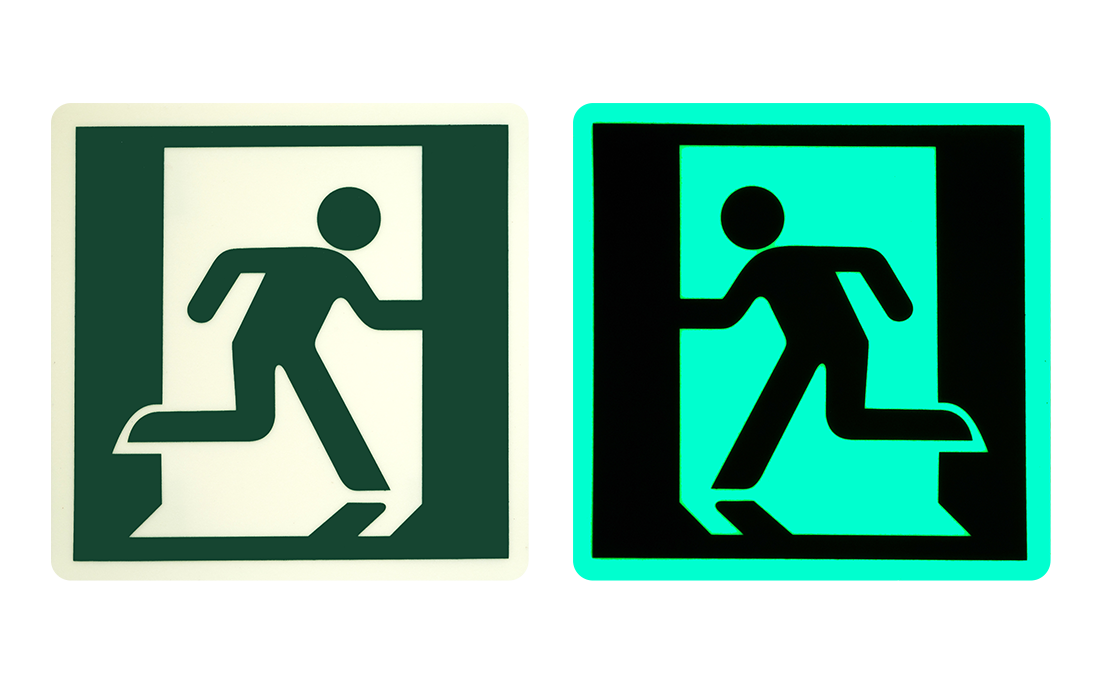

| Running Man Directional Sign | Model # | Description |

|---|---|---|

|

DRML, DRMR | Photoluminescent running man left or right “Pictogram” sign. Identifies the final exit door and informs occupants of the exit path through the final exit doorway.

|

Key Product Information

- Typical Applications: Placed centered on the final exit door, no higher than 18 inches from the floor, to inform occupants of the exit path through the final exit doorway. Designed to be clearly visible and understandable in emergencies and under all lighting conditions.

- Building Types: Commercial, Industrial, Residential, High Rise Buildings, Hospitals, Stadiums, Schools, Hotels, Multi-Use, Multi-Family, Apartment Buildings

- Supplied: 5” tall x 5” wide. Left (DRML). Right (DRMR).

- Background Options: Photoluminescent Acrylic (Standard), Non-Photoluminescent – contact Safe-T-Nose for options.

- Backing Options: Acrylic Film (Standard) White ⅛” PVC Rigid Board Backing (Upgrade), contact Safe-T-Nose for options.

- Attachment Options: Peel and stick backing included.

- Warranty: Up to 25 Years. Contact Safe-T-Nose for product warranty.

- Lifecycle: Up to 30 years with proper install and maintenance.

- Compliance: ASTM E2072 / UL 1994 / IBC / IFC / NFPA 101 / NFPA 170 / ICC A117.1

- Performance: A charging source of 1 ft-candle (11 lux) of fluorescent or natural light illumination is necessary for 60 minutes to ensure that minimum luminance requirements of 30 mcd/m2 at 10 minutes and 5 mcd/m2 at 90 minutes are met after failure of the main lighting.

- Running Man Directional Sign – DRML DRMR – Product One Sheet

| Combo Directional Signs | Model # | Description |

|---|---|---|

|

DRMC | Photoluminescent running man left or right “Pictogram” sign with directional arrow included. Various combinations for all conditions to direct occupants to final exit discharge.

|

Key Product Information

- Typical Applications: Placed centered on the final exit doors, no higher than 18 inches from the floor, on walls, and passageway walls to inform occupants to the final exit discharge. Designed to be clearly visible and understandable in emergencies and under all lighting conditions.

- Building Types: Commercial, Industrial, Residential, High Rise Buildings, Hospitals, Stadiums, Schools, Hotels, Multi-Use, Multi-Family, Apartment Buildings

- Supplied: Custom sized depending on selection.

- Background Options: Photoluminescent Acrylic (Standard), Non-Photoluminescent – contact Safe-T-Nose for options.

- Backing Options: Acrylic Film (Standard) White ⅛” PVC Rigid Board Backing (Upgrade), contact Safe-T-Nose for options.

- Attachment Options: Peel and stick backing included.

- Warranty: Up to 25 Years. Contact Safe-T-Nose for product warranty.

- Lifecycle: Up to 30 years with proper install and maintenance.

- Compliance: ASTM E2072 / UL 1994 / IBC / IFC / NFPA 101 / NFPA 170 / ICC A117.1

- Performance: A charging source of 1 ft-candle (11 lux) of fluorescent or natural light illumination is necessary for 60 minutes to ensure that minimum luminance requirements of 30 mcd/m2 at 10 minutes and 5 mcd/m2 at 90 minutes are met after failure of the main lighting.

- Combo Directional Signs – DRMC – Product One Sheet

| No Exit Sign | Model # | Description |

|---|---|---|

|

ENAE | Photoluminescent no exit sign. Identifies maintenance, closet and dead end pathways.

|

Key Product Information

- Typical Applications: Placed centered on doors, no higher than 18 inches from the floor, to inform occupants of a dead end. Designed to be clearly visible and understandable in emergencies and under all lighting conditions.

- Building Types: Commercial, Industrial, Residential, High Rise Buildings, Hospitals, Stadiums, Schools, Hotels, Multi-Use, Multi-Family, Apartment Buildings

- Supplied: 5” tall x 5” wide.

- Background Options: Photoluminescent Acrylic (Standard), Non-Photoluminescent – contact Safe-T-Nose for options.

- Backing Options: Acrylic Film (Standard) White ⅛” PVC Rigid Board Backing (Upgrade), contact Safe-T-Nose for options.

- Attachment Options: Peel and stick backing included.

- Warranty: Up to 25 Years. Contact Safe-T-Nose for product warranty.

- Lifecycle: Up to 30 years with proper install and maintenance.

- Compliance: ASTM E2072 / UL 1994 / IBC / IFC / NFPA 101 / NFPA 170 / ICC A117.1

- Performance: A charging source of 1 ft-candle (11 lux) of fluorescent or natural light illumination is necessary for 60 minutes to ensure that minimum luminance requirements of 30 mcd/m2 at 10 minutes and 5 mcd/m2 at 90 minutes are met after failure of the main lighting.

- No Exit Sign – ENAE – Product One Sheet

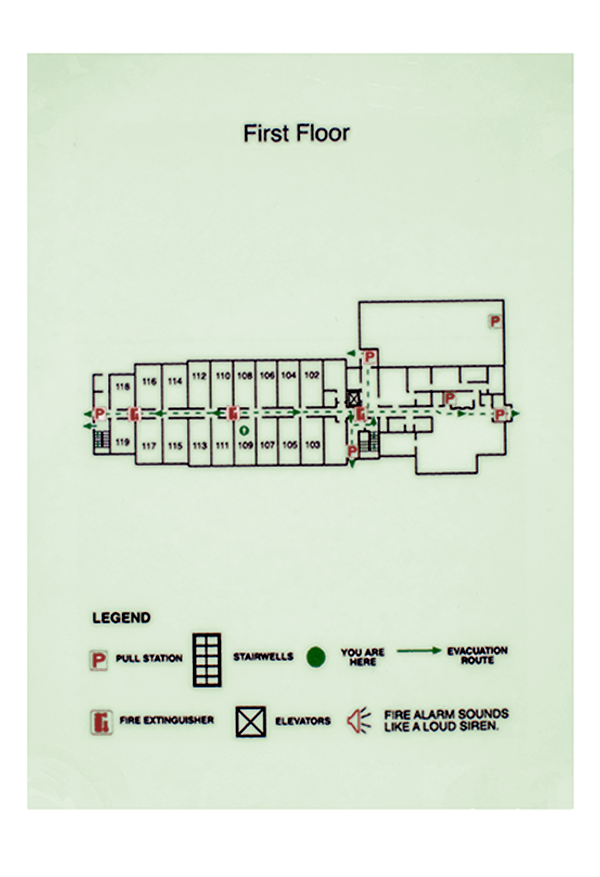

| Evacuation Map Sign | Model # | Description |

|---|---|---|

|

EVACFLTR | Photoluminescent custom made evacuation map sign. Displays path from current position to exit discharge location.

|

Key Product Information

- Typical Applications: Placed at elevator lobbies, dwelling doors. Displays path from current position to exit discharge location. Designed to be clearly visible and understandable in emergencies and under all lighting conditions.

- Building Types: Commercial, Industrial, Residential, High Rise Buildings, Hospitals, Stadiums, Schools, Hotels, Multi-Use, Multi-Family, Apartment Buildings

- Supplied: Custom designed and sized.

- Background Options: Photoluminescent Acrylic (Standard), Non-Photoluminescent – contact Safe-T-Nose for options.

- Backing Options: Acrylic Film on White ⅛” PVC Rigid Board Backing (Standard), contact Safe-T-Nose for options.

- Attachment Options: Peel and stick backing included.

- Warranty: Up to 25 Years. Contact Safe-T-Nose for product warranty.

- Lifecycle: Up to 30 years with proper install and maintenance.

- Compliance: ASTM E2072 / UL 1994 / IBC / IFC / NFPA 101 / NFPA 170 / ICC A117.1

- Performance: A charging source of 1 ft-candle (11 lux) of fluorescent or natural light illumination is necessary for 60 minutes to ensure that minimum luminance requirements of 30 mcd/m2 at 10 minutes and 5 mcd/m2 at 90 minutes are met after failure of the main lighting.

- Evacuation Map Sign – EVACFLTR – Product One Sheet

| Single Side Exit Sign | Model # | Description |

|---|---|---|

|

EUL50 | Photoluminescent single (one) sided exit sign. Placed centered above exit doors, or high / low level in corridors / hallways with included arrows to direct occupants to exit.

|

Key Product Information

- Typical Applications: Placed centered above exit doors, or high / low level in corridors / hallways with included arrows to direct occupants to exit. Designed to be clearly visible and understandable in emergencies and under all lighting conditions.

- Building Types: Commercial, Industrial, Residential, High Rise Buildings, Hospitals, Stadiums, Schools, Hotels, Multi-Use, Multi-Family, Apartment Buildings

- Supplied: 9” Tall x 16” Wide

- Text: Photoluminescent Letters

- Backing Options: Brushed Aluminum (Silver), Black, Green, Red.

- Attachment Options: Peel and stick backing or Mounting Bracket

- Warranty: Up to 25 Years. Contact Safe-T-Nose for product warranty.

- Lifecycle: Up to 30 years with proper install and maintenance.

- Compliance: ASTM E2072 / UL 1994 / UL 924, IBC / IFC / NFPA 101 / NFPA 170 / ICC A117.1

- Performance: A charging source of 1 ft-candle (11 lux) of fluorescent or natural light illumination is necessary for 60 minutes to ensure that minimum luminance requirements of 30 mcd/m2 at 10 minutes and 5 mcd/m2 at 90 minutes are met after failure of the main lighting.

- Single Side Exit Sign – EUL50 – Product One Sheet

| Double Side Exit Sign | Model # | Description |

|---|---|---|

|

EUL502 | Photoluminescent double (two) sided exit sign. Placed adjacent – centered above exit doors, or high / low level in corridors / hallways with included arrows to direct occupants to exit.

|

Key Product Information

- Typical Applications: Placed adjacent – centered above exit doors, or high / low level in corridors / hallways with included arrows to direct occupants to exit. Designed to be clearly visible and understandable in emergencies and under all lighting conditions.

- Building Types: Commercial, Industrial, Residential, High Rise Buildings, Hospitals, Stadiums, Schools, Hotels, Multi-Use, Multi-Family, Apartment Buildings

- Supplied: 9” Tall x 16” Wide

- Text: Photoluminescent Letters

- Backing Options: Brushed Aluminum (Silver), Black, Green, Red.

- Attachment Options: Optional Mounting Brackets

- Warranty: Up to 25 Years. Contact Safe-T-Nose for product warranty.

- Lifecycle: Up to 30 years with proper install and maintenance.

- Compliance: ASTM E2072 / UL 1994 / UL 924, IBC / IFC / NFPA 101 / NFPA 170 / ICC A117.1

- Performance: A charging source of 1 ft-candle (11 lux) of fluorescent or natural light illumination is necessary for 60 minutes to ensure that minimum luminance requirements of 30 mcd/m2 at 10 minutes and 5 mcd/m2 at 90 minutes are met after failure of the main lighting.

- Single Side Exit Sign – EUL502 – Product One Sheet

Code Review

Overview

This document provides guidance to local building officials, architects, and contractors as to the requirements for luminous egress path markings in new and existing high-rise buildings, in accordance with the 2021 International Building and Fire codes.

Compliance with these code sections will ensure a safe evacuation of residents during emergency conditions-potentially saving lives in the process.

- Related Downloads:

- Egress Path Markings – Code Review

LUMINOUS EGRESS PATH MARKINGS

1025.1 GENERAL

Approved luminous egress path markings delineating the exit path shall be provided in high-rise buildings of Groups A, B, E, I-1, M or R-1 occupancies in accordance with this section.

Exception: Luminous egress path markings shall not be required on the level of exit discharge in lobbies that serve as part of the exit path in accordance with Section 1028.1, Exception 1.

1025.2 MARKINGS WITHIN EXIT COMPONENTS

Egress path markings shall be provided in interior exit stairways, interior exit ramps and exit passageways, in accordance with Sections 1025.2.1 through 1025.2.6.

1025.2.1 STEPS

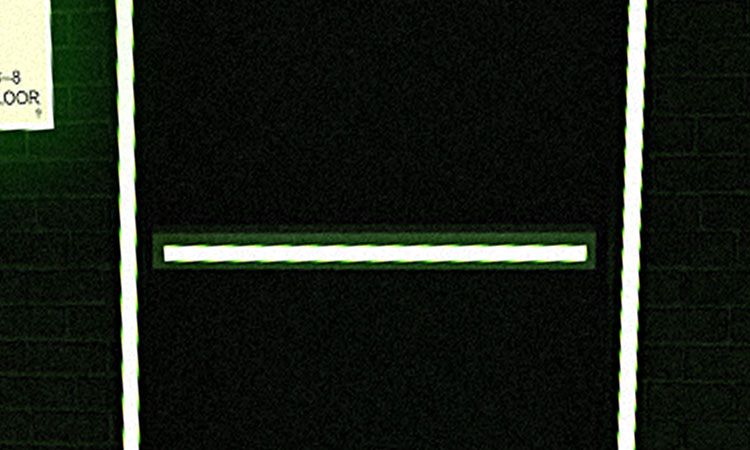

A solid and continuous stripe shall be applied to the horizontal leading edge of each step and shall extend for the full length of the step. Outlining stripes shall have a minimum horizontal width of 1 inch (25 mm) and a maximum width of 2 inches (51 mm). The leading edge of the stripe shall be placed not more than 1/2 inch (12.7 mm) from the leading edge of the step and the stripe shall not overlap the leading edge of the step by not more than 1/2 inch (12.7 mm) down the vertical face of the step.

Exception: The minimum width of 1 inch (25 mm) shall not apply to outlining stripes listed in accordance with UL 1994.

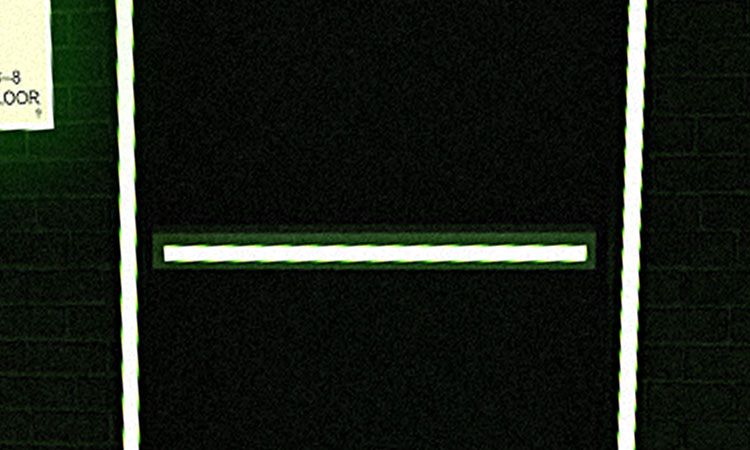

1025.2.2 LANDINGS

The leading edge of landings shall be marked with a stripe consistent with the dimensional requirements for steps.

1025.2.3 HANDRAILS

Handrails and handrail extensions shall be marked with a solid and continuous stripe having a minimum width of 1 inch (25 mm). The stripe shall be placed on the top surface of the handrail for the entire length of the handrail, including extensions and newel post caps. Where handrails or handrail extensions bend or turn corners, the stripe shall not have a gap of more than 4 inches (102 mm).

Exception: The minimum width of 1 inch (25 mm) shall not apply to outlining stripes listed in accordance with UL 1994.

1025.2.4 PERIMETER DEMARCATION LINES

Stair landings and other floor areas within interior exit stairways, interior exit ramps and exit passageways, with the exception of the sides of steps, shall be provided with solid and continuous demarcation lines on the floor or on the walls or a combina- tion of both. The stripes shall be 1 to 2 inches (25 mm to 51 mm) wide with interruptions not exceeding 4 inches (102 mm).

Exception: The minimum width of 1 inch (25 mm) shall not apply to outlining stripes listed in accordance with UL 1994.

1025.2.4.1 FLOOR-MOUNTED DEMARCATION LINES

Perimeter demarcation lines shall be placed within 4 inches (102 mm) of the wall and shall extend to within 2 inches (51 mm) of the markings on the leading edge of landings. The demarcation lines shall continue across the floor in front of all doors.

Exception: Demarcation lines shall not extend in front of exit discharge doors that lead out of an exit and through which occupants must travel to complete the exit path.

1025.2.4.2 WALL-MOUNTED DEMARCATION LINES

Perimeter demarcation lines shall be placed on the wall with the bottom edge of the stripe not more than 4 inches (102 mm) above the finished floor. At the top or bottom of the stairs, demarcation lines shall drop vertically to the floor within 2 inches (51 mm) of the step or landing edge. Demarcation lines on walls shall transition vertically to the floor and then extend across the floor where a line on the floor is the only practical method of outlining the path.

Exception: Demarcation lines shall not extend in front of exit discharge doors that lead out of an exit and through which occupants must travel to complete the exit path.

1025.2.4.3 TRANSITION

Where a wall-mounted demarcation line transitions to a floor-mounted demarcation line, or vice versa, the wall-mounted demarcation line shall drop vertically to the floor to meet a complimentary extension of the floor-mounted demarcation line, thus forming a continuous marking.

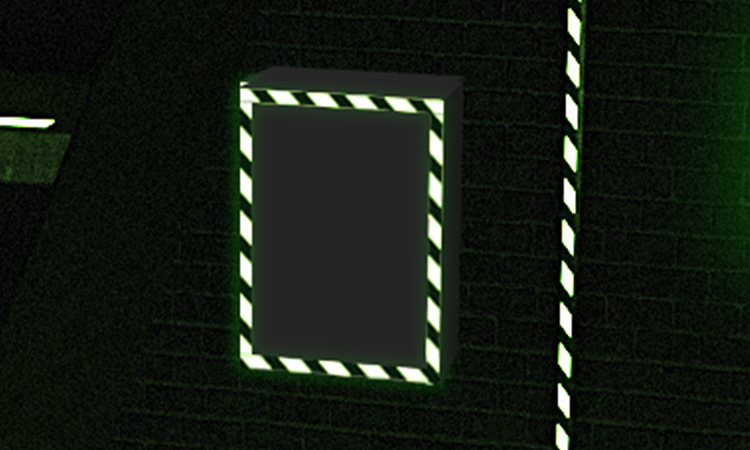

1025.2.5 OBSTACLES

Obstacles at or below 6 feet 6 inches (1981 mm) in height and projecting more than 4 inches (102 mm) into the egress path shall be outlined with markings not less than 1 inch (25 mm) in width comprised of a pattern of alternating equal bands, of luminous material and black, with the alternat- ing bands not more than 2 inches (51 mm) thick and angled at 45 degrees (0.79 rad). Obstacles shall include, but are not limited to, standpipes, hose cabinets, wall projections and restricted height areas However, such mark- ings shall not conceal any required information or indicators including but not limited to instructions to occupants for the use of standpipes.

1025.2.6 DOORS WITHIN THE EXIT PATH

Doors through which occupants must pass in order to complete the exit path shall be provided with markings complying with Sections 1025.2.6.1 through 1025.2.6.3.

1025.2.6.1 EMERGENCY EXIT SYMBOL

The doors shall be identified by a low-location luminous emergency exit symbol complying with NFPA 170. The exit symbol shall be not less than 4 inches (102 mm) in height and shall be mounted on the door, centered horizontally, with the top of the symbol not higher than 18 inches (457 mm) above the finished floor.

1025.2.6.2 DOOR HARDWARE MARKINGS

Door hardware shall be marked with not less than 16 square inches (406 mm2) of luminous material. This marking shall be located behind, immediately adjacent to, or on the door handle or escutcheon. Where a panic bar is installed, such material shall not be less than 1 inch (25 mm) wide for the entire length of the actuating bar or touchpad.

1025.2.6.3 DOOR FRAME MARKINGS

The top and sides of the door frame shall be marked with a solid and continuous 1-inch- to 2-inch-wide (25 mm to 51 mm) stripe. Where the door molding does not provide sufficient flat surface on which to locate the stripe, the stripe shall be permitted to be located on the wall surrounding the frame.

1025.1 GENERAL

1025.2.1 STEPS

1025.2.2 LANDINGS

1025.2.3 HANDRAILS

1025.2.4 PERIMETER DEMARCATION LINES

1025.2.4.1 FLOOR-MOUNTED DEMARCATION LINES

1025.2.4.2 WALL-MOUNTED DEMARCATION LINES

1025.2.4.3 TRANSITION

1025.2.5 OBSTACLES

1025.2.6 DOORS WITHIN THE EXIT PATH

1025.2.6.1 EMERGENCY EXIT SYMBOL

1025.2.6.2 DOOR HARDWARE MARKINGS

1025.2.6.3 DOOR FRAME MARKINGS

1025.1 GENERAL

Approved luminous egress path markings delineating the exit path shall be provided in high-rise buildings of Groups A, B, E, I-1, M or R-1 occupancies in accordance with this section.

Exception: . Luminous egress path markings shall not be required on the level of exit discharge in lobbies that serve as part of the exit path in accordance with Section 1028.1, Exception 1.

1025.2 MARKINGS WITHIN EXIT COMPONENTS

Egress path markings shall be provided in interior exit stairways, interior exit ramps and exit passageways, in accordance with Sections 1025.2.1 through 1025.2.6.

1025.1

GENERAL

1025.2.1 STEPS

A solid and continuous stripe shall be applied to the horizontal leading edge of each step and shall extend for the full length of the step. Outlining stripes shall have a minimum horizontal width of 1 inch (25 mm) and a maximum width of 2 inches (51 mm). The leading edge of the stripe shall be placed not more than 1/2 inch (12.7 mm) from the leading edge of the step and the stripe shall not overlap the leading edge of the step by not more than 1/2 inch (12.7 mm) down the vertical face of the step.

Exception: The minimum width of 1 inch (25 mm) shall not apply to outlining stripes listed in accordance with UL 1994.

1025.2.1

STEPS

1025.2.2 LANDINGS

The leading edge of landings shall be marked with a stripe consistent with the dimensional requirements for steps.

1025.2.2

LANDINGS

1025.2.3 HANDRAILS

Handrails and handrail extensions shall be marked with a solid and continuous stripe having a minimum width of 1 inch (25 mm). The stripe shall be placed on the top surface of the handrail for the entire length of the handrail, including extensions and newel post caps. Where handrails or handrail extensions bend or turn corners, the stripe shall not have a gap of more than 4 inches (102 mm).

Exception: The minimum width of 1 inch (25 mm) shall not apply to outlining stripes listed in accordance with UL 1994.

1025.2.3

HANDRAILS

1025.2.4 PERIMETER DEMARCATION LINES

Stair landings and other floor areas within interior exit stairways, interior exit ramps and exit passageways, with the exception of the sides of steps, shall be provided with solid and continuous demarcation lines on the floor or on the walls or a combina- tion of both. The stripes shall be 1 to 2 inches (25 mm to 51 mm) wide with interruptions not exceeding 4 inches (102 mm).

Exception: The minimum width of 1 inch (25 mm) shall not apply to outlining stripes listed in accordance with UL 1994.

1025.2.4

PERIMETER DEMARCATION LINES

1025.2.4.1 FLOOR-MOUNTED DEMARCATION LINES

Perimeter demarcation lines shall be placed within 4 inches (102 mm) of the wall and shall extend to within 2 inches (51 mm) of the markings on the leading edge of landings. The demarcation lines shall continue across the floor in front of all doors.

Exception: Demarcation lines shall not extend in front of exit discharge doors that lead out of an exit and through which occupants must travel to complete the exit path.

1025.2.4.1

FLOOR-MOUNTED DEMARCATION LINES

1025.2.4.2 WALL-MOUNTED DEMARCATION LINES

Perimeter demarcation lines shall be placed on the wall with the bottom edge of the stripe not more than 4 inches (102 mm) above the finished floor. At the top or bottom of the stairs, demarcation lines shall drop vertically to the floor within 2 inches (51 mm) of the step or landing edge. Demarcation lines on walls shall transition vertically to the floor and then extend across the floor where a line on the floor is the only practical method of outlining the path.

Exception: Demarcation lines shall not extend in front of exit discharge doors that lead out of an exit and through which occupants must travel to complete the exit path.

1025.2.4.2

WALL-MOUNTED DEMARCATION LINES

1025.2.4.3 TRANSITION

Where a wall-mounted demarcation line transitions to a floor-mounted demarcation line, or vice versa, the wall-mounted demarcation line shall drop vertically to the floor to meet a complimentary extension of the floor-mounted demarcation line, thus forming a continuous marking.

1025.2.4.3

TRANSITION

1025.2.5 OBSTACLES

Obstacles at or below 6 feet 6 inches (1981 mm) in height and projecting more than 4 inches (102 mm) into the egress path shall be outlined with markings not less than 1 inch (25 mm) in width comprised of a pattern of alternating equal bands, of luminous material and black, with the alternat- ing bands not more than 2 inches (51 mm) thick and angled at 45 degrees (0.79 rad). Obstacles shall include, but are not limited to, standpipes, hose cabinets, wall projections and restricted height areas However, such mark- ings shall not conceal any required information or indicators including but not limited to instructions to occupants for the use of standpipes.

1025.2.5

OBSTACLES

1025.2.6 DOORS WITHIN THE EXIT PATH

Doors through which occupants must pass in order to complete the exit path shall be provided with markings complying with Sections 1025.2.6.1 through 1025.2.6.3.

1025.2.6

DOORS WITHIN THE EXIT PATH

1025.2.6.1 EMERGENCY EXIT SYMBOL

The doors shall be identified by a low-location luminous emergency exit symbol complying with NFPA 170. The exit symbol shall be not less than 4 inches (102 mm) in height and shall be mounted on the door, centered horizontally, with the top of the symbol not higher than 18 inches (457 mm) above the finished floor.

1025.2.6.1

EMERGENCY EXIT SYMBOL

1025.2.6.2 DOOR HARDWARE MARKINGS

Door hardware shall be marked with not less than 16 square inches (406 mm2) of luminous material. This marking shall be located behind, immediately adjacent to, or on the door handle or escutcheon. Where a panic bar is installed, such material shall not be less than 1 inch (25 mm) wide for the entire length of the actuating bar or touchpad.

1025.2.6.2

DOOR HARDWARE MARKINGS

1025.2.6.3 DOOR FRAME MARKINGS

The top and sides of the door frame shall be marked with a solid and continuous 1-inch- to 2-inch-wide (25 mm to 51 mm) stripe. Where the door molding does not provide sufficient flat surface on which to locate the stripe, the stripe shall be permitted to be located on the wall surrounding the frame.

1025.2.6.3

DOOR FRAME MARKINGS

1025.3 UNIFORMITY

Placement and dimensions of markings shall be consistent and uniform throughout the same enclosure.

1025.4 SELF-LUMINOUS AND PHOTOLUMINESCENT

Luminous egress path markings shall be permitted to be made of any material, including paint, provided that an electrical charge is not required to maintain the required luminance. Such materials shall include, but not be limited to, self-luminous materials and photoluminescent materials. Materials shall comply with either of the following standards:

- UL 1994.

- ASTM E2072, except that the charging source shall be 1 footcandle (11 lux) of fluorescent illumination for 60 minutes, and the minimum luminance shall be 30 milicandelas per square meter at 10 minutes and 5 milicandelas per square meter after 90 minutes.

1025.5 ILLUMINATION

Where photoluminescent exit path markings are installed, they shall be provided with not less than 1 footcandle (11 lux) of illumination for not less than 60 minutes prior to periods when the building is occupied and continuously during occupancy.

2018 IFC/IBC 1023.9 STAIRWAY IDENTIFICATION SIGNS

A sign shall be provided at each floor landing in an interior exit stairway and ramp connecting more than three stories desig- nating the floor level, the terminus of the top and bottom of the interior exit stairway and ramp and the identification of the stairway or ramp. The signage shall state the story of and direction to the exit discharge, and the availability of roof access from the interior exit stairway and ramp for the fire department. The sign shall be located 5 feet (1524 mm) above the floor landing in a position that is readily visible when the doors are in the open and closed positions. In addition to the stairway identification sign, a floor-level sign in visual characters, raised characters and braille complying with ICC A117.1 shall be located at each floor-level landing adjacent to the door leading from the interior exit stairway and ramp into the corridor to identify the floor level.

1023.9.1 SIGNAGE REQUIREMENTS

- The signs shall be a minimum size of 18 inches (457 mm) by 12 inches (305 mm).

- The letters designating the identification of the interior exit stairway and ramp shall be not less than 11/2 inches (38 mm) in height.

- The number designating the floor level shall be not less than 5 inches (127 mm) in height and located in the center of the sign.

- Other lettering and numbers shall be not less than 1 inch (25 mm) in height.

- Characters and their background shall have a nonglare finish. Characters shall contrast with their background, with either light characters on a dark background or dark characters on a light background.

- Where signs required by Section 1023.9 are installed in the interior exit stairways and ramps of buildings subject to Section 1025, the signs shall be made of the same materials as required by Section 1025.4.

1023.9.1 SIGNAGE REQUIREMENTS

Disclaimer: Information contained here is for informational purposes only. The information is not to be construed as endorsements or recommendation for its use. While National Stair Products believes the information contained herein is accurate to the best of our knowledge, National Stair Products makes no warranty, express or implied with respect to the accuracy or readability of this information. The product data is offered for your consideration, investigation and verification. Your building code official must approve for your intended use.

Code Compliant, High- Grade photoluminescence path markings.

The International Building Code mandates the installation of photoluminescent egress path markings in stairwells and passageways to ensure safety and wayfinding in emergency situations. In addition to floor markings, buildings are required to mark handrails and obstructions, enhancing overall building safety by facilitating swift and efficient evacuation during emergencies.

In compliance with the International Building Code, the International Fire Code, NFPA, UL 1994, UL 924, ASTM E2072, and CAN/ULC-S572.

We provide multiple grades of products, high-grade materials for high-traffic applications, or value-engineered solutions when low use of pathways is expected.