PRECAST CONCRETE STAIR TREADS

Recycled Lightweight Precast Concrete Stair Treads & Landing Plank

The Alternative To Concrete Pan Filled Stairs and Landings

Eliminate building egress systems with costly concrete-filled pan stairs, loud diamond plate stairs, or heavy precast stairs and stair treads.

Our precast stair steps are built with a patented core, coated with 8,500 psi concrete. A single 48″ wide tread weighs only 34 pounds. A 70% reduction in concrete, VOC emissions, and weight when compared to traditional precast stair treads.

These concrete treads minimize labor, cleanup, and logistical handling. The lightweight design minimizes job-site injuries and offers clients major cost savings all around.

Designed to be set on top of flat metal stair pans. After the final painting of the stair, these treads are installed just before occupancy for a clean finish. Clients achieve an instant concrete stair without the traditional associated costs.

Download:

- For eliminating pan filled metal stairs and landings

- ASTM E84 Fire-rated Class 1 / Class A building material

- A 100% recycled plastic core coated with concrete

- Single profile-lengths up to 6 feet

- Anti-slip finish

- Consistent epoxy painted finish

- Abrasive metal nosing, contrasting stripe, photoluminescent marking options

Product Information:

Click Headings Below For More Information

Applications

Overview

These precast concrete stairs treads are designed to minimize production, freight, install and maintenance costs. Our treads utilize a patented 100% recycled material core coated with high performing cement to minimize the use of concrete, greatly reducing weight and CO2 emissions.

1. Eliminate Pan Filled Stairs

- Metal stairs are fabricated with metal flat stair pans to accept the precast concrete tread.

- The metal stair tread offers instant egress during construction.

- Paint the stairs just before occupancy.

- Quickly install Rhino Tred precast concrete treads for an instant concrete finish.

- Easily replace treads in the future as needed to renew the stair system without needing to remove the entire metal stair system.

2. Restore Existing Stairs

- Dated buildings or damage from corrosion, rust, or heavy use often require stairs to be repaired.

- Minimize restoration costs by only replacing stair treads and salvaging stair stringers, railings, and landings.

- Restoration company removes the aged stair pans or precast treads.

- Rhino Tred and Universal Flat Pan are supplied to the job site.

- The installer welds or bolts Flat Pan to existing stringers.

- The Flat Pan is pre-galvanized or painted on site to match the stringers and rail.

- Rhino Tred is attached to the Flat Pan for instant use.

3. A Cost Savings Stair Design

- Rhino Tred is made of recycled materials and high performing cement, with 70% weight reduction.

- Metal Pans close the risers, but also offer the load support. Rhino Tred is a simple, lightweight concrete finish.

- Less weight means less material, less freight, and easy install, creating cost savings all around.

Inspiration

- Architectural-Looking Stairs

- Eliminate On Site Concrete Pour

- Easier Precast Concrete Tread Install

- Reduced precast concrete tread failure

- Lightweight and Nationally Available

- Wood Stair Hybrid Design – Using Wood Stringers, Metal Angle Clips, Metal Pan, Finished With Precast Concrete Tread

- Apartment Stair Alternative – The lightweight Rhino Tred stair treads offer tough durability, lightweight install, and is easily replaced

- Metal Diamond or Checker Plate Alternative – concrete treads are quieter when walked on.

Products

Overview

Rhino Tred is a single profile product with optional add ons. This precast concrete stair tread is designed to always be supported by metal stair pans. The precast tread serves as a durable, lightweight concrete finish for stairs.

| Rhino Tred Standard | Model # | Nominal Dimension (in x in) (+/- ⅛”) | Description |

|---|---|---|---|

|

RT-PC150 | 1.5″ x 11.625″ x Specified |

|

| Rhino Tred STNR Surface Mount | Model # | Nominal Dimension (in x in) (+/- ⅛”) | Description |

|---|---|---|---|

|

RT-PC150-STNR | 1.5″ x 11.625″ x Specified |

|

| Rhino Tred STNR Flush Mount | Model # | Nominal Dimension (in x in) (+/- ⅛”) | Description |

|---|---|---|---|

|

RT-PC150-SG-STNR | 1.5″ x 11.625″ x Specified |

|

| Rhino Tred STNS Flush Mount | Model # | Nominal Dimension (in x in) (+/- ⅛”) | Description |

|---|---|---|---|

|

RT-PC150-SG-STNS | 1.5″ x 11.625″ x Specified |

|

| Rhino-Tred STNC3 Embedded | Model # | Nominal Dimension (in x in) (+/- ⅛”) | Description |

|---|---|---|---|

|

RT-PC150-STNC3 | 1.5″ x 11.625″ x Specified |

|

Colors

Overview

Rhino Tred precast concrete stair treads are manufactured with a standard color to maintain a consistent product model. During manufacturing, the wet cement is finished with a sand grit coat and gray epoxy floor paint to seal the sand bond. The final product is highly non-slip. The product arrives on site with a consistent anti-slip finish already applied. Should the Rhino Tred need to be refinished in the future, gray epoxy floor paint is readily available.

STANDARD COLORS:

Disclaimer: Actual color may vary between monitors and printers. Due to the manufacturing process, slight variations of color and texture will occur.

Textures

Overview

Rhino Tred arrives with a standard anti-slip texture. Embedded sand is coated with epoxy floor paint to create a highly non-slip walking surface.

Standard Sand and Epoxy Floor Paint Texture:

Benefits

Overview

Rhino Tred is a lightweight precast concrete stair tread to eliminate: on site cast in place concrete, pan filled stairs, weight imposed on the building structure, and many costs associated with traditional concrete finished stairs.

Product Benefits

- One Standard Stair Tread Profile – 1.5” x 11.625” x Required Stair Width

- The Metal Stair with Flat Pans Offer Full Use of Stairs on the Job Site, Before Installation of Rhino Tred

- Manufactured with a Patented Honeycomb Core, Coated with UHPC 8,500 PSI Concrete

- Built Lightweight to Ship Nationally and for Easy Install

- 70% Less Weight than Traditional Precast Concrete Stair Treads

- With Less Concrete, CO2 Emissions are Reduced by Up to Two Thirds, a LEED Points Opportunity

- Embedded Sand and Epoxy Finish Provides a Superior “Pool Deck” Slip Resistant Finish

- The Stairwell can be Finish Painted Before Installation

- No Concrete Clean-up After Installation

- Precast Treads can be Provided with Nosing Options

- Significant Noise Reduction and Better Slip Resistance Compared to Checker Plate Stairs

Cost Benefits

- Greater Cost-Effectiveness by Eliminating Pan Filled Stairs

- The Metal Flat Pans Do Not Require Wood Infills to Utilize Stairs During Construction

- Installed After Finish Paint for an Instant “New Concrete” Finish Just Before Occupancy

- Lighter Weight – Faster and Easier Installation, & Less Shipping Costs

- Minimized Job Site Injury

- No Install Lifting Machinery

- Less Field Erection Labor Needed

- No Concrete Sub-Contractor Costs

- No Concrete Clean Up Costs

- Less “Product Loss” Due to Shipping or Installation Breakage

- Restoration Made Easy, Refinish with New Epoxy Paint Coat

- Easily Remove and Replace Without Replacing Entire Stair System

Scheduling Benefits

- Faster Scheduling Timing – Stocked Profile

- Lightweight to Fit Large Quantities on a Single Truck Load

- Lightweight for Fast Installation

- No Concrete Sub-Contractor Scheduling Issues or Weather Delays

- No Cleaning Required Since Concrete Pour is Eliminated

Nosings

Overview

Stair Nosing and Stripe options supplied by Safe-T-Nose.

Enhance the slip-resistance and visibility of the stair treads. Abrasive, ribbed, contrasting stripe, grip strip or photoluminescent strip options available. Applied to the leading edge of the stair tread with using embedded method, marine grade adhesive, and/or mechanical fasteners.

Stair Nosing / Contrasting Stripe Options

The aluminum stair nosing and contrasting stripe options are available in nine available combinations below.

Black Traction Stripe

Yellow Traction Stripe

Glow Stripe

Glow Stripe / Lights Off

Black Traction Stripe

Yellow Traction Stripe

Glow Stripe

Glow Stripe / Lights Off

Black Traction Stripe

Yellow Traction Stripe

Glow Stripe

Glow Stripe / Lights Off

2” Surface Mount Stair Nosing:

The most affordable and popular solution. The low profile aluminum nosing attaches to the top face. Shop applied or on site by others using recommended marine grade adhesive for a permanent application.

2” Flush Mount Stair Nosing:

Additional costs and lead time apply. A product modification made during manufacturing to accept the stair nosing for a flush transition. The low profile aluminum nosing attaches to the recess. Shop applied using marine grade adhesive for a permanent application.

1.5” Flush Mount Stair Nosing:

Additional costs and lead time apply. A product modification made during manufacturing to accept the stair nosing for a flush transition. The low profile aluminum nosing attaches to the recess. Shop applied using marine grade adhesive for a permanent application.

3” Embedded Stair Nosing:

Additional costs and lead time apply. This nosing option is embedded into the wet concrete pour during manufacturing for a flush transition.

STNR

Flush Mount

Images

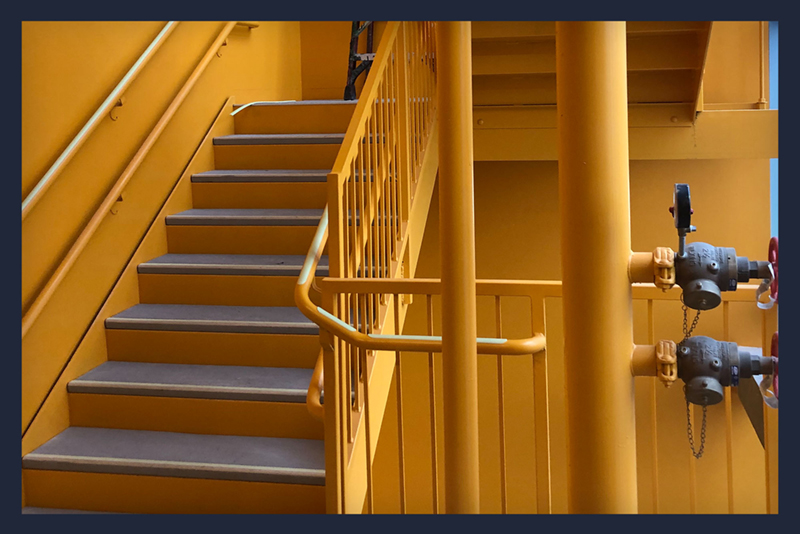

Overview

Precast Concrete Stair Tread images – showcasing product fabrication, assembly, features, and job site install.

Installation

Finished Projects

Videos

Overview

Watch our Rhino Tred videos.

Rhino Tred | 1:36

Product Introduction Video

Rhino Tred | 3:00

Product Manufacturing Video

Drawings

Overview

Discover durable and visually appealing staircase designs with our comprehensive design details for Rhino Tred precast concrete stair treads. Whether you’re envisioning metal or wood stairs, or for interior or exterior spaces, our design resources provide invaluable insights. Rhino Tred’s innovative technology ensures longevity and resilience, making it an ideal choice for a wide range of applications.

Installation

Overview

Rhino Tred eliminates all cost associated with pan filled stair treads. During construction the metal stair flat pans offer a non-trip walking surface for accessing floor levels. Just before occupancy of the building the metal stairs are cleaned, often finish painted, and Rhino Tred is quickly installed for an instant concrete finish.

INSTALLATION IS PERFORMED BY ANY TRADE.

Job site hand, carpenters, flooring contractors, concrete contractors can install. No special tools are required. The product arrives ready to install.

Drop On Installation:

During install and 72 hour after (minimum cure time). Stairwell must keep 50 Degrees Fahrenheit or higher. This is the minimum install and cure time temperature.

- Begin installation at the top of the stair, continuing down to avoid walking on the installed product.

- Prior to application of adhesive. Surface(s) to be dry, free of dust and debris. Using a clean cotton cloth, with Simple Green solvent or mineral spirits, wipe surface(s) thoroughly where adhesive is to be applied.

- At the bottom side of Rhino Tred. At each plugged hexagon. Apply 1/4” thick adhesive dabs, the size of a quarter.

- Gently set the tread on to the metal flat pan. Centered between stair stringers. The front base of the tread is not to overhang the nosing of the metal flat pan.

- Press down firmly across the tread to allow adhesive to expand across the flat pan.

- Allow a minimum of 72 hours for adhesive cure time. Do not walk on Rhino Tred.

Maintenance

Overview

Rhino Tred has been designed for minimal maintenance and replacement. The high performance concrete with inner core is durable. The finish sand and epoxy floor paint coating is easily re-applied with a brush as needed to restore the new finish look. If damage beyond repair occurs, remove the precast tread with a crowbar and re-apply a new tread for easy restoration.

CARE AND CLEANING

- Do not use salts, deicers, or chemicals on stairs as this will corrode concrete, paint, metal stair, adhesives and voids warranty.

- Brush or blow off debris.

- Wash with water and soft brush.

- Do not pressure wash.

- Refinish sand and epoxy floor paint finish as visually needed.

STORAGE

- Do Not Stack or Lean. Lay Flat ONLY.

- Do not remove from factory packaging.

- Store covered from elements.

- Store in ambient temperature / room temperature.

- Keep away from heat sources.

ONSITE INSPECTION, MAINTENANCE, RESTORATION, REPLACEMENT

- Perform a regular visual inspection to identify excessive damage which may create tripping hazards. Replace damaged treads by using a crowbar to remove and install a new tread to restore.

- Heavy foot traffic, exposure to elements, or contaminants may wear the abrasive epoxy floor paint finish over time. Rhino Tred can be restored by applying a new coat of sand and epoxy floor paint finish. Contact us for locations to purchase restoration materials.

- Cracking is common in all concrete. Hairline cracks are not a failed product as the inner core continues to serve as the precast treads structural component. Hairline cracks can be concealed by re-applying a new coat of sand and epoxy floor paint finish on site.

- If replacement treads are needed. Contact us to provide the required length of product and quantity.

Warranty

Overview

Rhino Tred is designed to be a durable cost savings alternative to on site cast in place stair treads. The inner core is made from recycled plastic. Coated with 8,500 psi concrete. Finished with sand and epoxy floor paint to create a consistent color and abrasive walking surface. The final product reduces weight and CO2 emissions.

Warranty Summary

Rhino Tred is warranted to be free of defects from workmanship and materials for the period of one year from the date of original purchase delivery. Should any problem develop during this one year period, and upon inspection by an authorized agent of National Redi-Tread where the inspection determines the trouble is caused by defective workmanship or material, National Redi-Tread will replace the product in question without charge.

Please review the Rhino Tred Limited Product Warranty document for complete information.

Rhino Tred – Limited Product Warranty

National Stair Products is committed to delivering products of the highest quality and craftsmanship. We stand behind our workmanship and materials, and as such, we offer the following limited warranty.

Important Note: Cracking is common in all concrete. Hairline cracks are not defects from workmanship and materials. The inner core continues to serve as the precast treads structural component if hairline cracks are visible. Hairline cracks can be concealed by applying a new coat of sand and epoxy floor paint finish on site. The cost of refinishing is not covered by the limited warranty.

(a) What this Limited Warranty Covers:

This Limited Warranty covers manufacture defects and substantial defects directly caused by workmanship and materials.

(b) How Long This Limited Warranty Lasts:

Subject to the terms and conditions of the Limited Product Warranty, National Stair Products (NSP) (hereinafter “Manufacturer,” “We” or “Us”) warrants to the original consumer (”Consumer” or “You” of NSP, (”Products”) that, manufactured defective product will be replaced for a period of one (1) year from the date of purchase, and in normal applications the Products will not shatter, corrode, or suffer structural damage during this period when installed for normal use interior applications.

(c) What is Covered:

If the Products are found to be defective, We, in our sole discretion will promptly repair or replace the defective Products, or refund Your full purchase price for the Products only (excluding labor). Refunds if any will only apply to that portion of Products that are actually determined to be defective, regardless of the collective amount of Products or services purchased from Us or others.

(d) What is Not Covered:

Labor, installation and/or reinstallation, other associated costs, removal of Product, inspection, architect, contractor or engineer expenses, shipping, freight costs, fabrication, and time for on-site examination by others of proposed defects are not included with this limited warranty and shall not be paid by Us. This limited warranty only applies to Products directly manufactured by Us, which are returned to Us with transportation charges prepaid by You. Under no circumstances will We be responsible for ancillary costs and expenses incurred such as labor, removal, installation, re-installation, storage, time, freight or any other charge incurred by You, related to defective product. You are solely responsible for determining the suitability of use or application of any Product and whether Product meets the requirements of applicable building codes for specific applications. We do not warrant or guarantee, and You or your contractors are solely and exclusively responsible for determining (i) suitability of using Products in any particular application and/or design, and (ii) structural integrity and safety of all structures of any kind whatsoever constructed in whole or in part using Products. You and your contractor must review Manufacturer’s Product Specifications and consult with an architect, engineer, and other design professionals to determine suitability and applicability to local and/or national building and safety code regulations regarding all applications of Products.

We will have no warranty obligation with respect to the Product if any of the following events occur: (a) the Product is subjected to abuse, misuse, negligence, improper or abnormal use, failure to maintain, fire, or any accident including without limitation, acts of God, or environmental pollutants; (b) installation, storage, handling, fabrication, engineering, service, maintenance, or use of the Product which is not in accordance with the written installation requirements and/or is performed improperly, negligently, or by unqualified or unauthorized personnel or without competent supervision and as specified by Our literature, applicable laws regulations and industry standards (c) movement and/or collapse of the ground or structure on which the assemblage(s) incorporating the Product is installed (d) any variation of color, including but not limited to fading, discoloration and spotting (e) issues arising from expansion and contraction of sub structure (f) the Product is materially altered or modified (except if prior written approval of Manufacturer is obtained after the original installation); or (g) We have not received full payment for the invoice price of the order containing the warranted Product.

(e) How to Get Service:

To make a warranty claim under this Limited Product warranty, We shall receive from You (i) proof of date of purchase and purchase price, (ii) a photograph of the Product depicting the defect, (iii) a written description of claimed defects with name, address and contact information of the installer, if available. You shall send the warranty claim by mail within 30 days of discovering the claimed defect(s) to Attn: Warranty Claims Dept, National Stair Products, P.O. Box 9118 Brooks, OR 97305. No alterations or repair shall be made prior to the warranty claim. You shall give Us (or our agents) reasonable access to the property and location where the Products are located for inspection purposes and shall retain such Products for inspection.

(f) Exclusive Limited Warranty:

WE UNDERTAKE NO RESPONSIBILITY FOR THE QUALITY OF THE PRODUCTS EXCEPT AS OTHERWISE PROVIDED HEREIN. TO THE EXTENT PERMITTED BY LAW, OUR LIMITED PRODUCT WARRANTY AND THE REMEDIES SET FOR HEREIN ARE YOUR SOLE AND EXCLUSIVE REMEDY AND ARE OFFERED BY US IN LIEU OF ALL OTHER WARRANTIES, GUARANTEES AND/OR REMEDIES WHATSOEVER, INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR PURPOSE, OR OTHER WARRANTIES OR GUARANTEES ARISING BY OPERATION OF LAW, WHICH ARE HEREBY EXPRESSLY DISCLAIMED. WE ASSUME NO RESPONSIBILITY THAT THE PRODUCTS WILL BE FIT FOR ANY PARTICULAR PURPOSE FOR WHICH YOU MAY BE BUYING THE PRODUCTS, EXCEPT AS OTHERWISE PROVIDED HEREIN. TO THE EXTENT THE PRODUCTS ARE INSTALLED FOR CONSUMER APPLICATION, THE FOREGOING DISCLAIMERS MAY NOT APPLY. IN NO EVENT SHALL WE BE LIABLE TO PURCHASER OR THIRD PARTIES FOR SPECIAL, INCIDENTAL, CONSEQUENTIAL, PUNITIVE, ECONOMIC, EXEMPLARY OR OTHER SIMILAR DAMAGES.

(g) Limitation of Liability:

Purchaser agrees that Our entire liability, under any warranty, whether in contract, in tort, in negligence or otherwise shall not exceed the amount of the purchase price paid. UNDER NO CIRCUMSTANCES SHALL NATIONAL STAIR PRODUCTS BE LIABLE FOR CONSEQUENTIAL, SPECIAL OR INCIDENTAL DAMAGES, LOST PROFITS, LOSS OF BUSINESS OR ANY OTHER ECONOMIC DAMAGES. The price stated for the Product is based upon and in consideration for limiting Our liability. Neither Manufacturer nor its representatives approve, recommend, or perform design review for specific applications of the Product(s). No person or entity is authorized by Us to make, and We shall not be bound by any statement or representation as to the performance or Product other than what is contained in this Limited Warranty. This Limited Warranty shall not be amended or altered except in a written instrument signed by You and Us. ALL CLAIMS, CAUSES OF ACTION OR DEMANDS SHALL BE MADE WITHIN ONE (1) YEAR AFTER THE DEFECT IS DISCOVERED OR THE CLAIM OCCURRED. ALL CLAIMS OR CAUSES OF ACTION WITH RESPECT TO THE PRODUCTS SHALL EXCLUSIVELY BE ASSERTED IN A COURT OF COMPETENT JURISDICTION LOCATED IN SALEM, OREGON.

(h) How State Law Applies:

SOME STATES DO NOT ALLOW LIMITATIONS OF THE DURATION OF IMPLIED WARRANTIES OR THE EXCLUSIONS OR LIMITATIONS OF INCIDENTAL OR CONSEQUENTIAL DAMAGES. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU MAY HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STATE.

Additional Warranty Information:

This warranty does not apply where:

- Product has been abused, misused, or improperly installed.

- Alterations have been made to the product.

- Regular maintenance instructions are neglected.

Cracks are unfortunately common in concrete. While you may notice a superficial hairline crack, due to our patented core and high-performance mix, they do not affect the integrity of the tread. Therefore, they do not void the warranty.

In no event shall National Stair Proucts be liable for any indirect, incidental, or consequential damages from the sale or use of its products. This disclaimer applies both during and after the term of this warranty. National Stair Products disclaims liability for any implied warranties, including implied warranties of “merchantability” and “fitness for a specific purpose”, after the one-year term of this warranty. This Warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

FOR YOUR PROTECTION

The carrier who delivers merchandise to your door or job site is responsible for loss and damages. Acceptance of the shipment by the transportation company is acknowledgment that the articles delivered were in good condition and properly packed.

CONCEALED DAMAGE

If damage is noticed when merchandise is unpackaged, notify the transportation company’s office immediately and ask to have it inspected. Do not destroy packing materials until shipment is inspected and claims settled.

All claims or loss or damage should be filed immediately with the transportation company making delivery to your door or job site, then notify National Stair Products. We will mark our records accordingly. Should you need assistance with the claims we will be glad to help.

Note: Do not reject or return damaged merchandise to the transportation company. The transportation company will pick up after settling the claims.

IMPORTANT: RETURN GOODS CANNOT BE RETURNED WITHOUT WRITTEN AUTHORITY

Call or email National Stair Products for return authorization number (RMA). All shipments not having this number will be refused. All shipments returned for credit or exchange when the error is not ours will be subject to the following:

- 15% restocking charge, and

- Material must be returned – shipping prepaid by customer.

Downloads Library

Overview

Download our current product resources. Contact us for questions.

- One Sheets

- Rhino-Tred – Cost Comparison vs Steel Pan Filled Stairs

- CAD Details

- Models

- Nosings

- Detail Binder

Disclaimer: Information contained here is for informational purposes only. The information is not to be construed as endorsements or recommendation for its use. While National Stair Products believes the information contained herein is accurate to the best of our knowledge, National Stair Products makes no warranty, express or implied with respect to the accuracy or readability of this information. The product data is offered for your consideration, investigation and verification. Your building code official must approve for your intended use.

Build a lightweight, instant concrete stair without the traditional associated costs.

Eliminate building egress systems with costly concrete-filled pan stairs, loud diamond plate stairs, or heavy precast stairs and stair treads.

Our precast stair steps are built with a patented core, coated with 8k+ psi concrete. A single 48″ wide tread weighs only 34 pounds. 70% reduction in concrete, VOC emissions, and weight when compared to traditional precast stair treads.

These concrete treads minimize labor, cleanup, and logistical handling. The lightweight design minimizes job-site injuries. Offering clients major cost savings all around.

Designed to be set on top of flat metal stair pans. After the final painting of the stair, these treads are installed just before occupancy for a clean finish. Clients achieve an instant concrete stair without the traditional associated costs.

Message Us

Downloads

Precast Concrete Stair Treads and Riser: The Perfect Solution for Your Concrete Staircase

Outline:

- Introduction

- The Importance of Stair Treads

- What are they?

- Advantages

- Customization Options: Colors, Sizes, and Finishes

- Installation Process and Manufacturers

- Projects and Experiences

- Maintaining the Quality of Stair Treads

- Bullet Point Summary

Product Introduction: Precast Concrete Stair Treads

Concrete stairs are a common feature in both residential and commercial buildings. Not only do they serve a functional purpose, but they also add to the aesthetic appeal of the space. One crucial component of a concrete staircase is the stair tread, which provides a stable surface for people to walk on. In this article, we will explore the importance of stair treads, discuss precast concrete stair treads in detail, and explain why they are the perfect solution for your staircase.

The Importance of Precast Concrete Stair Treads and Risers:

Stair treads play a vital role in staircase safety. They provide a stable and non-slip surface for people to walk on, reducing the risk of slips, falls, and injuries. Additionally, stair treads protect the underlying concrete from wear and tear, extending the lifespan of the staircase. When choosing stair treads, it is essential to consider the material and design that best suits the overall aesthetic of the space. Precast concrete stair treads provide an excellent solution due to their durability, strength, and versatility.

What are Precast Concrete Stair Treads?

Precast concrete stair treads and steps are manufactured off-site and then installed on the staircase. They are made using a mold that allows for consistent dimensions and a high-quality finish. The standard precast treads are reinforced with rebar for added strength and can be customized to meet specific project requirements. They are available in standard sizes or can be custom-made to fit any staircase design.

Advantages:

Precast concrete stair treads offer several advantages over other types of stair treads. Firstly, they are incredibly durable and can withstand heavy foot traffic for an extended period. They are resistant to damage from glacial wear and tear, ensuring the longevity of your staircase. Additionally, precast concrete stair treads are easy to install, saving time and labor costs. Unlike poured-in-place concrete, precast treads do not require on-site curing, allowing for faster project completion.

Construction Options: Colors, Sizes, and Finishes:

One of the significant advantages of precast concrete stair treads is the flexibility to customize various aspects of the product. They are available in a wide range of colors, allowing you to match the treads with the overall design scheme of your space. Precast treads also come in different sizes, ensuring a perfect fit for your staircase, including bolt-on. Additionally, you can choose from various finishes, such as broom finish or smooth, depending on your preference and project requirements.

Manufacturer of precast concrete products

National Stair Products specializes in the production of precast concrete stair treads. NSP has the experience, reputation, and the precast stair tread products you need. National Stair Products will help you with custom precast concrete stair treads that meet your exact specifications. We can assist you from architectural drawing to engineering to a quality stair treads application from our construction experience in this industry.

Projects and Experiences:

Many projects across different industries have benefitted from the use of precast concrete stair treads. From residential buildings to commercial spaces, precast treads offer a reliable and aesthetically pleasing solution. Architects, contractors, and designers have extensively used precast concrete stair treads to meet their project requirements. The largest precast concrete steps company in the market today quote an extensive inventory of treads, ensuring that every stairways needs are met.

Maintaining the Quality of Stair Treads:

To ensure the durability and longevity of your precast concrete stair treads, proper maintenance is essential. Regular inspections should be carried out to check for any signs of wear, damage, or structural issues. Cleaning the treads regularly and addressing any issues promptly will help maintain their quality. It is also crucial to follow the manufacturer's guidelines regarding maintenance and care to maximize the lifespan of the stair treads.

Summary:

- Stair treads are essential for staircase safety and protection.

- Precast concrete stair treads offer durability, strength, and versatility.

- Customization options include colors, sizes, and finishes.

- Installation of precast treads is straightforward and can be done by professionals.

- Several manufacturers provide high-quality precast concrete stair treads.

- Projects across various industries benefit from precast treads.

- Regular maintenance is necessary to ensure the longevity of the stair treads.

Precast concrete stair treads are an ideal choice for anyone looking to enhance the safety and aesthetics of their staircase. Their durability, customization options, and ease of installation make them a superior product in the market today. By investing in precast concrete stair treads, you can ensure the long-term functionality and visual appeal of your staircase.

Frequently Asked Questions

4 inches At minimum, the concrete thickness should be 4 inches between the inside of the step to the ground. In order to determine the number of risers, divide the total height of the steps by the number of risers desired. No individual riser should be greater than 7 to 7½ inches.

With all three options, the inside area of concrete steps is hollow. The top of the step and porch top are usually 4-6 inches of concrete while the sides are 6-8 inches. This can be either 6-8 inches of solid concrete or cinder block. Rebar is typically used inside the steps and porch top to add strength.

Caulk and Seal Carefully Carefully apply a waterproof epoxy caulk along all joints in between the steps and along walls, as well as any cracks the power washing exposed. Backer rods should be installed in cases of severe cracking or significant gaps between joints. Jun 12, 2019

Yes, concrete steps need rebar to reinforce the structure and ensure it can hold weight over time. Place a lattice of rebar inside the form before pouring concrete to give the steps their maximum strength. Jul 10, 2023

How thin can you pour concrete over concrete? Your new layer needs to be at least 2 inches thick. If it’s any thinner than that, it’ll easily crack under pressure and won’t adequately bond to your surface.