PRECAST POLYMER STAIR TREADS & LANDING PLANKS

The world's only fiber reinforced polymer product that is IBC compliant for both exterior and interior stairs for all construction types.

A Better Precast Stair Tread Solution

Perma-Tread provides cost savings and long lasting stair tread solutions for new and renovated staircases, including platforms, decks, and more.

The precast polymer product meets commercial building codes both locally and internationally, making polymer a dependable choice for indoor and outdoor applications.

Designed to look like concrete and available in many colors and options; Perma-Tread eliminates the risks of cracking, chipping, fading, or deterioration.

Download:

- Many profiles, colors, and textures are available

- It won’t crack, chip, fade, stain, or deteriorate

- Structural-rated, fire-rated, slip resistant

- Impervious to weather, salt, and chemicals

- Easy install, maintenance free, 50+ year lifespan

- Made with recycled content, 100% recyclable

Product Information:

Click Headings Below For More Information

Applications

Overview

Perma-Tread precast polymer stair treads offer a versatile and durable alternative to traditional stair tread materials. Engineered for longevity and resilience, these innovative treads provide a seamless blend of aesthetic appeal and robust performance. Whether enhancing indoor spaces or withstanding the rigors of outdoor environments, Perma-Tread stands as a reliable choice for those seeking superior stair tread solutions that effortlessly marry style and durability.

1. Stair Treads

- Self-spanning open riser stairs as alternative to precast concrete treads.

- Supported closed riser stairs as alternative to pan filled stairs.

- Exterior & Interior stair systems.

2. Stair Landing & Platform Plank

- Self-spanning plank as alternative to precast concrete plank.

- Supported plank as alternative to concrete filled landings.

3. Decks, Balcony, Porch, Docks, Walkways, Boardwalks

- Self-spanning between joists.

- Finish surface on floor assembly.

Inspiration

- Treads, Risers, Decking, Planks

- Posts, Joists, Beams, Structural Lumber

- Interior Stairs

- Exterior Stairs

- Stair Restoration / Renovation

- Wood Frame Stair Treads and Landing Plank

- Metal Stair Treads and Landing Plank

- Precast Stair Treads and Landing Plank

- Cast-In-Place Stair Treads and Landing Plank

- Residential Stairs and Decking

- Apartment Stairs and Decking

- Commercial Stair Treads and Landing Plank

- Egress Stairs

- Fire Escape Stairs

- Monumental Stairs / Grand Stairs

- Industrial Stairs

- Manufacturing Plant Stairs

- Roof Stairs

- Ships Ladders

- Access Stairs

- Loft Stairs

- Dock Stairs / Balcony Stairs

- Cross Over Stairs

- Open Riser Stair Treads

- Closed Riser Stair Treads

- Alternative to Wood Stair Treads

- Alternative to Carpet Stair Treads

- Alternative to Rubber Stair Treads

- Alternative to Vinyl Stair Treads

- Alternative to Plastic Stair Treads

- Alternative to Fiberglass Stair Treads

- Alternative to Composite Stair Treads

- Alternative to Metal Stair Treads

- Alternative to Concrete Stair Treads

- Alternative to Pan Filled Stairs

- Alternative to Diamond Plate / Checker Plate Stairs

- Alternative to Bar Grating Stair Treads

- Alternative to Aluminum Stair Treads

Drawings

Overview

Discover durable and visually appealing staircase designs with our comprehensive design details for Perma-Tread polymer stair treads. Whether you’re envisioning steel or wood stairs, or for interior or exterior spaces, our design resources provide invaluable insights. Perma-Tread’s innovative polymer technology ensures longevity and resilience, making it an ideal choice for a wide range of applications.

Products

Overview

Multiple profiles for different applications are available. Design your structure to accept Perma-Tread profiles as an alternative to metal, concrete, stone, wood, composite decking, landing plank, stair treads and more.

Minimum orders apply per profile as product is manufactured per job.

Standard Stair Tread & Landing/Platform Plank Profiles

| Shape | Model No. | Nominal Profile | Actual Dimension (in x in) (+/- ⅛) | Longest Length (ft) | Approx. Weight (lbs/ft) |

|---|---|---|---|---|---|

|

212 | 2 x 2 | 1.5 x 11.25 | 16 | 6.5 |

|

312 | 3 x 12 | 2.5 x 11.25 | 16 | 10.8 |

|

412 | 4 x 12 | 3.5 x 11.25 | 20 | 15 |

Alternative Landing/Platform Plank Profiles

| Shape | Model No. | Nominal Profile | Actual Dimension (in x in) (+/- ⅛) | Longest Length (ft) | Approx. Weight (lbs/ft) |

|---|---|---|---|---|---|

|

TG210 | Tongue & Groove 2 x 10 | 1.5 x 9.1 | 16 | 5.5 |

|

TG310 | Tongue & Groove 3 x 10 | 2.4 x 8.75 | 20 | 8.9 |

|

224 | 2 x 24 True | 2 x 24 | 10 | 20.6 |

|

324 | 3 x 24 True | 3 x 24 | 10 | 31.1 |

Additional Nominal Lumber Profiles

(Treads, Tread Risers, Plank, Deck Board, Posts, Studs, Joists, Beams, Structural Lumber)

| Shape | Model No. | Nominal Profile | Actual Dimension (in x in) (+/- ⅛) | Longest Length (ft) | Approx. Weight (lbs/ft) |

|---|---|---|---|---|---|

|

5/44 | 5/4 x 4 | 1.1 x 3.5 | 8 | 1.5 |

|

5/46 | 5/4 x 6 | 1.1 x 5.5 | 12 | 2.3 |

|

5/48 | 5/4 x 8 | 1.1 x 7.5 | 12 | 3.1 |

|

24 | 2 x 4 | 1.5 x 3.5 | 16 | 2.2 |

|

26 | 2 x 6 | 1.5 x 5.5 | 16 | 3.5 |

|

28 | 2 x 8 | 1.5 x 7.5 | 18 | 4.44 |

|

210 | 2 x 10 | 1.5 x 9.25 | 16 | 5.4 |

|

34 | 3 x 4 | 2.5 x 3.5 | 16 | 3.4 |

|

36 | 3 x 6 | 2.5 x 5.5 | 16 | 5.1 |

|

38 | 3 x 8 | 2.5 x 7.5 | 16 | 7.0 |

|

310 | 3 x 10 | 2.5 x 9.5 | 16 | 8.9 |

|

44 | 4 x 4 | 3.5 x 3.5 | 16 | 4.8 |

|

46 | 4 x 6 | 3.5 x 5.5 | 20 | 7.2 |

|

48 | 4 x 8 | 3.5 x 7.5 | 20 | 9.8 |

|

410 | 4 x 10 | 3.5 x 9.5 | 20 | 14.1 |

Colors

Overview

Standard colors are most popular and are readily available. Special colors require per-project manufacturing and are subject to additional cost and longer order fulfillment time. All colors are 100% through, meaning any scratch or scuff will not affect the color. Perma-Tread is UV rated, will not fade, contains no harmful chemicals, and will not decay.

STANDARD COLORS:

SPECIAL COLORS:

Disclaimer: Actual color may vary between monitors and printers. Due to the manufacturing process, slight variations of color and texture will occur.

Textures

Overview

Textures redefine the tactile and visual experience of the product. The textures offer a reliable and functional solution for different interior or exterior stair tread, plank, or deck applications.

Standard Texture:

The standard texture is the most affordable and popular option. This finish resembles the concrete look. The orange peel-like texture withstands high foot traffic, vehicle use, and machinery use. It is ideal for residential, commercial, and industrial applications. The texture is naturally highly slip-resistant, exceeding slip rating requirements dry or wet.

Grooved Texture:

Additional costs and lead time apply—a product modification made to the standard texture after the precast process. A highly abrasive ribbed / bar grating-like effect creates grooves which promotes drainage to the left and right. The grooves can be placed at the leading edge for stair tread abrasive nosing or through the top face. This texture withstands high foot traffic without wear and greatly enhances slip rating. It is ideal for industrial stairs, ships ladders, landings, platforms, and planking, where high slip resistance for walking is required.

Embossed Wood Grain Texture:

Additional costs and lead time apply—an embossed wood grain modification to the standard texture after the precast process. This texture is only available for up to 12” broad profiles. Embossment depth may vary due to product tolerances. It is not recommended for high-use applications. This texture is for mid to low-use residential stairs, landings, and decks.

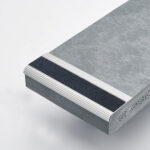

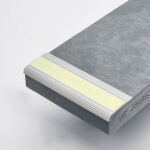

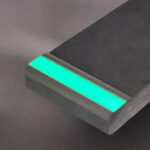

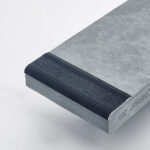

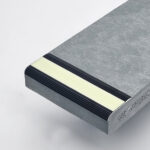

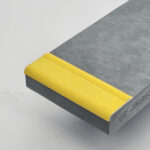

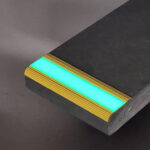

Nosings & Contrasting Stripe

Overview

Enhance the slip-resistance and visibility of the stair treads. Abrasive, ribbed, contrasting stripe, grip strip, or photoluminescent strip options available.

Stair Nosing and Stripe options supplied by Safe-T-Nose.

Stair Nosing / Contrasting Stripe Options:

The low profile aluminum nosing attaches to the top face with marine grade adhesive and/or mechanical fasteners.

Black Traction Stripe

Yellow Traction Stripe

Glow Stripe

Glow Stripe (Lights Off)

Black Traction Stripe

Yellow Traction Stripe

Glow Stripe

Glow Stripe (Lights Off)

Black Traction Stripe

Yellow Traction Stripe

Glow Stripe

Glow Stripe (Lights Off)

Benefits

Overview

Lightweight structural profiles, highly slip-resistant surface, and impenetrable characteristics to harsh weather, salt, chemicals, and corrosion make Perma-Tread the ideal alternative building material for stairs, landings, and decks.

Product Benefits

- 3 Standard Stair Tread Profile Options – 2 x 12, 3 x 12, & 4 x12

- Stair Landing, Platform, Deck Board Profile Options – Including Tongue & Groove

- 3 Non-Skid Surface Options – Standard, Grooved, and Embossed Wood Grain

- 5 Standard Colors / 13 Total Colors

- Fire-Rated – Class A (Metal Pan Assembly) & Class B (Free Span Fully Exposed to Flame)

- Structural & Can Free-Span Up To 60” at 122 Deg. F.

- Custom Lengths or Full-Length Options up to 20 linear feet.

- Multiple Stair Nosing Options – Color, Style, Abrasive, & Photoluminescent

- Multiple Installation Methods – Commercial Adhesive, Screws, Through Bolts

- Cut & Drill with Standard Tools – No Special Equipment Required

- Ultra-Violet (UV) & Chemically Resistant

- Impervious to Pests, Weather, & Salt

- Non-Cracking, Non-Chipping, & Non-Fading

- Non-Rotting, Non-Bleeding, & Non-Staining

- International & Local Building Code, OSHA, and LEED Compliant

- Made with Recycled Materials / 100% Recyclable

Cost Benefits

- Product Durability Offers Greater Cost-Effectiveness

- Lighter Weight – Faster and Easier Installation & Less Shipping Costs

- Minimized Job Site Injury

- Less Field Erection Labor Needed

- No Install Lifting Machinery Needed

- No Concrete Sub-Contractor Costs

- No “Product Loss” Due to Shipping or Installation Breakage

- Less Maintenance – Cheaper and Easier to Clean with No “Concrete Sealing” Required

- Minimized or Eliminated Future Replacement – Will Not Decay, Rot, Corrode, Rust or Fade.

Scheduling Benefits

- Faster Scheduling Timing – Stocked Profiles & Colors

- Handled Like Lumber For Fast Installation

- Easily Modified, Site Cuts and Modifications can be done with Standard Tools

- No Concrete Sub-Contractor Scheduling Issues or Weather Delays

- No Waiting For Replacement Product Due to Loss.

Cost Comparison

Overview

Perma-Tread polymer precast stair treads revolutionize traditional stair design by minimizing costs across material procurement, fabrication, installation, maintenance, and future replacements. Engineered for efficiency, the product is designed to optimize material usage beyond the tread without compromising the structural integrity of the stair design, resulting in substantial savings. With a focus on durability, Perma-Tread ensures a long-lasting solution that reduces initial expenses and also offers a sustainable choice for both interior and exterior stair applications.

Cost Comparison #1

Perma-Tread vs Traditional Open Riser Metal Stair With Precast Concrete Treads

4 Foot Wide Stairs, 18 Treads, Single 4 Foot x 8 Foot Mid. Landing.

| Perma-Tread | Traditional System | |

|---|---|---|

| Total Invesment After New Installation | $13,775 | $17,560 |

| Total Investment After 5-20 Years (Heavily Used Stair) | $13,775 (No Maintenance, No Replacement, No Reinvesment) | $50,000+ (Due To Concrete Corrosion: 20 Years Of Maintenance + Demolition + Complete Replacement) |

| Total Investment After 20-40 Years (Heavily Used) | $13,775 (No Maintenance, No Replacement, No Reinvestment) | $100,000+ (Maintenance + Total Replacement X 2) |

| Line Item Breakout | Perma-Tread Stair System Cost | Traditional Stair System Cost |

|---|---|---|

| Steel Stair, Landing, Railing Structure Fabrication + Local Delivery Cost | $9,000 (All Material, Fabrication, Galvanized) | $9,000 (All Material, Fabrication, Galvanized) |

| Steel Structure Installation Labor | $400 (2 Hours x 2 Workers) | $400 (2 Hours x 2 Workers) |

| Total Tread Weight – (18) 4x12x48 Treads | 1,080 Lbs. (60 Lbs. Each) | 2,790 Lbs. (175 Lbs. Each) |

| Tread Freight Cost | $500 (Box Truck, Single Pallet) | $1,500 (Flat Bed, Multiple Pallets) |

| Small Mobile Installation Crane Rental | $0 (Not Needed) | $250 (24 Hour Rental) |

| Tread Cost – (18) 4x12x48 Treads | $2,610 ($145 each – 412 Profile) | $2,880 ($160 each – 4 x 12 Profile) |

| Tread Damage/Loss (Before Install) | (0% Loss) | $480 (15% Loss – 3 Extra Treads) |

| Product Onsite Machinability | Yes (Modify With Standard Tools) | No (Concrete Can’t Be Modified) |

| Tread Install Labor Hours | $400 (2 Hours x 2 Workers) | $2,000 (5 Hours x 4 Workers) |

| Landing Plank Cost (Perma-Tread System Only) | $665 ((5) 8 Foot Plank) | N/A (Requires Pan Filled Landing) |

| Landing Plank Install Labor (Perma-Tread System) | $200 (1 Hour x 2 Workers) | N/A (Requries Pan Filled Landing) |

| Landing Material Delivery Cost (Traditional Pan Fill Landing) | $0 (Included With Tread Delivery) | $200 (Concrete + Short Load Fee) |

| Concrete Landing Finish Labor (Traditional Pan Fill Landing System) | $0 (Plank Installs Like Treads) | $600 (2 Hours x 3 Workers) |

| Damage to Finish on Steel structure from direct contact with Chemicals or Abrasion | $0 (Product is Non- Abrasive, Non-Corrosive) | $250 (Average Repair + Touch Up Labor After Install) |

| Injury Rate | Low Due to Product Weight Reduction | High Due to Heavy Installation |

| Chemicals & Salt | Chemicals Okay, Salt Okay, Harsh Elements Okay | No Chemicals, No Salt, Must Protect & Maintain Against Elements |

| Manufacturer Defect Warranty | 1 Year | 1 Year |

| Annual Inspection, Maintenance, Finish Seal, Repair Investment | $0 (Product is Non-Corrosive, Will Not Stain or Absorb Chemicals) | $200 (Per Year) |

| Lifespan | Minimum 30 Years. Maximum 50+ Years. (Maintenance Free) | Minimum 5-20 Years. Maximum 20-40 Years. (Requires Regular Maintenance) |

Images

Overview

These images showcase the quality, durability, and lasting solution of Perma-Tread as an alternative stair tread, landing, and deck finish. Featured below is inspiration for residential, commercial, or industrial applications.

TEXAS – HOTEL

Pan Filled Metal Stair Replacement and Metal Stair Rail Salvage

The original metal stairs experienced major corrosion created by rain and moisture exposure. Over time, the metal stairs became a curb appeal issue and ultimately the corrosion created an unsafe stair for hotel visitors. To save costs, the customer had a local metal fabricator remove the original stairs, remove the rail, fabricate new stair frames and reinstall the original rail. Perma-Tread was installed as an alternative to precast concrete to provide a corrosion resistant solution. The end result was a faster, lightweight install, with stairs that won’t corrode again when they are exposed to the costal environment.

OREGON – WAREHOUSE OSHA STAIRS

Interior Application

Perma-Tread was selected because of immediate availability, no loss, cost savings, no maintenance, non-corrosive properties, and for long lifespan as an alternative to precast concrete treads.

GEORGIA – NEW APARTMENT STAIRS

Exterior Application

A new 150 apartment unit project with 26 stairways. The metal stairs we’ve fabricated with metal flat pans to accept Perma-Tread 212 as an instant alternative finish to precast concrete treads. The selected color was Weathered Concrete to resemble a traditional concrete look. Perma-Tread offered a lighter weight solution which greatly saved freight and installation costs. Perma-Tread was selected because of immediate availability, no loss, cost savings, no maintenance, non-corrosive properties, and for long lifespan as an alternative to precast concrete treads.

MARYLAND – EXISTING APARTMENT STAIR REPLACEMENT

Exterior Application

The original metal stairs of this existing apartment home complex were protected from the elements; however, concrete filled landings and precast concrete treads deteriorated over the years due to the humid climate. Perma-Tread 312 wet cement was selected as an alternative replacement solution to concrete. Perma-Tread was selected because of construction cost savings, free-span structural characteristics, no maintenance requirements, and non-corrosive properties.

OREGON – NEW RESIDENTIAL DECK STAIR

Exterior Application

This new residential deck stair was originally designed for open riser precast concrete treads. When weight and durability of concrete became a concern after the metal stair structure was installed, sourcing concrete treads became an issue for the homeowner. Perma-Tread 412 Dark Gray was selected as the final solution. The material was cut to size on site with ordinary tools and installed like lumber. Free spanning between stringers attached to seat angles from underneath.

IDAHO, EXISTING PAN FILLED STAIR RESTORATION

Exterior Application

A food processing facility needed to repair their exterior metal pan filled stairs to resolve safety concerns created by concrete corrosion. Concrete was removed from the stair pans. Perma-Tread 212 Wet Cement was selected. Cut to size on site, modified to fit the metal pan, and dropped in for an instant finish creating a better result that will not corrode again.

ASTM Testing

Overview

Perma-Tread is a commercial grade structurally molded, fire-rated, fiberglass polymer product. Tests have been performed to verify the product meets IBC / IFC building code requirements and ASTM test standards.

See technical data for test results.

ASTM D6109

Max Span Flexural Test

Tests were performed to provide builders and fabricators span ratings for many uses and applications: free span or supported stair treads, landing plank, deck boards, etc.

ASTM E84

Surface Burning of Building Materials for Flame Spread and Smoke Development

Tests were performed to verify Perma-Tread is an acceptable alternative to wood and an acceptable material to be used as an alternative floor finish. Testing was performed using two methods.

ASTM E303

Pendulum Slip Resistance Dry and Wet

Slip tests were performed to verify Perma-Tread meets slip resistant requirements as a walking surface. Dry and wet results perormed on the standard texture demonstrate the material can be used for any floor application.

Additional ASTM Tests

The International Building Code prescribes requirements for building materials. Various ASTM tests must be performed to confirm compliance for different applications.

- ASTM D6109 – Flexural Strength

- ASTM D6109 / D6108 – Compression Strength

- ASTM D7032 – Moisture Test

- ASTM D1929 – Spontaneous Ignition

- ASTM E648 – Radiant Heat

- ASTM D6341 – Thermal Expansion

- ASTM D6117 – Screw Pull Out

- ASTM D2344 – Shear Strength

Technical Data

Overview

The following information describes the structrual and durability of Perma-Tread. Made from recycled HDPE & LDPE with Recycled Fiberglass for structure with an UV additive to prevent deterioration. Designed to not rot, split, crack, or splinter. It is resistant to termites, salts, oil, mildew, and mold.

Perma-Tread Technical Data (Standard Profiles)

Dimensions

| Perma-Tread 212 | Perma-Tread 312 | Perma-Tread 412 | Perma-Tread T&G 210 | |

|---|---|---|---|---|

| Actual Depth | 11.25” | 11.25” | 11.25” | 9.1” |

| Actual Thickness | 1.5” | 2.5” | 3.5” | 1.5” |

| Length | Up to 16′ | Up to 16′ | Up to 20′ | Up to 16′ |

| Weight | 6.5 Lbs. +/- Lf | 11 Lbs. +/- Lf | 15 Lbs. +/- Lf | 5.5 Lbs. +/- Lf |

Maximum Free Span Live Load Tables at 78 °F

| Perma-Tread 212 | Perma-Tread 312 | Perma-Tread 412 | Perma-Tread T&G 210 | |

|---|---|---|---|---|

| 60 Lbs. / Sq. Ft. | 37.9″ | 59.4″ | 82.5″ | 37.9″ |

| 85 Lbs. / Sq. Ft. | 34.1″ | 53.7″ | 75.0″ | 34.1″ |

| 100 Lbs. / Sq. Ft. | 32.4″ | 51.2″ | 71.6″ | 32.4″ |

| 150 Lbs. / Sq. Ft. | 28.5″ | 45.2″ | 63.5″ | 28.5″ |

| 200 Lbs. / Sq. Ft. | 26.0″ | 41.3″ | 58.1″ | 26.0″ |

Maximum Free Span Live Load Tables at 122 °F

| Perma-Tread 212 | Perma-Tread 312 | Perma-Tread 412 | Perma-Tread T&G 210 | |

|---|---|---|---|---|

| 60 Lbs. / Sq. Ft. | 32.1″ | 50.3″ | 69.8″ | 32.1″ |

| 85 Lbs. / Sq. Ft. | 28.9″ | 45.5″ | 63.5″ | 28.9″ |

| 100 Lbs. / Sq. Ft. | 27.4″ | 43.4″ | 60.6″ | 27.4″ |

| 150 Lbs. / Sq. Ft. | 24.1″ | 38.3″ | 53.7″ | 28.5″ |

| 200 Lbs. / Sq. Ft. | 22.0″ | 35.0″ | 49.2″ | 24.1″ |

Fire Rating

| ASTM E84 (Metal Stair Assembly) |

ASTM E84 (Fully Exposed To Flame) |

|

|---|---|---|

| Class Rating | A | B |

| Flame Spread Index | 0 | 65 |

| Smoke Developed Index | 20 | 350 |

Slip rating

| ASTM E303 (Pendulum Slip Resitance) |

|

|---|---|

| Dry | 90 |

| Wet | 47 |

PROPERTIES

| ASTM Test | Value / Units | |

|---|---|---|

| Specific Gravity | D6111 | 0.93 |

| Flexural Strength | D6109 | 2,750 psi |

| Flexural Modulus (Secant, at 1% strain) | D6109 | 306 ksi |

| Compressive Strength (Perpendicular to grain) | D6108 | 1,482 psi |

| Compressive Modulus (Perpendicular to grain, Secant, at 1% strain) | D6108 | 54 ksi |

| Coefficient of Thermal Expansion | D6341 | 0.000033 in/in/°F |

| Static Coefficient of Friction – Dry | D2047 | 0.73 average |

| Static Coefficient of Friction – Wet | D2047 | 0.90 average |

| Impact Resistance (Izod) | D256 | 2.64 ft-lb/in |

| Water Absorption | D570 | 0.27% max by weight |

| Screw Withdrawal | D6117 | 646 lbs |

| Useful Temperature Range | -40°F to +140°F |

All above values shall be considered average except flexural strength. This value must have appropriate reduction factors set by the engineer of record.

material properties

| Description of Test Method | ASTM | Value / Units | |

|---|---|---|---|

| Brittleness | Standard Test Method for Brittleness Temperature of Plastics and Elastomers by Impact | D746-07 | No break at -40°F |

| Density and Specific Gravity | Standard Test Methods for Density and Specific Gravity of Plastics by Displacement | D792 | 58 lbs/cu.ft 0.0336 lbs/cu.in Specific Gravity: 0.93 |

| Hardness-Shore D | Standard Test Method for Rubber Property—Durometer Hardness | D2240- Type D | 80 |

| Abrasion Resistance | Standard Test Method for Abrasion Resistance of Organic Coatings by Taber Abraser | D4060 CS17 Wheel 10,000 cycles 2.2lb load | Weight Loss 0.023g / 0.043% |

| Ignition Temperature | Standard Test Method for Determining Ignition Temperature of Plastics; Flash Point / Ignition Temperature | D1929-96 | 824°F (440°C) |

| UV: Effect on Hardness | Standard Practice for Florescent UV Exposure of Plastics | D4329 & D2240 | 500 hrs: <1% Change in Hardness |

| Chemical Resistance | Standard Practices for Evaluation the Resistance of Plastics to Chemical Reagents | D543-06 | Sea Water: 0.06% weight increase |

| Chemical Resistance | Standard Practices for Evaluation the Resistance of Plastics to Chemical Reagents | D543-06 | Gasoline: 3.0% weight increase |

| Chemical Resistance | Standard Practices for Evaluation the Resistance of Plastics to Chemical Reagents | D543-06 | No.2 Diesel: 1.05% weight increase |

National Stair Products does not provide engineering services and assumes no responsibility, or liability, for any element of a projects design and/or construction details.

Disclaimer: Information contained in this TDS is taken from information provided by the suppliers of our raw materials. While National Stair Products believes the information contained herein is accurate to the best of our knowledge, National Stair Products makes no warranty, express or implied with respect to the accuracy or readability of this information. This data is offered for your consideration, investigation and verification.

Safety Data

Overview

Perma-Tread is manufactured from recycled HDPE, non-toxic materials. Essential information is provided for regulatory compliance and to ensure the safety of individuals who may come in contact with the product.

Sections Contained in Download:

- Product and Company Information

- Hazards Identification

- Composition / Information on Ingredients

- First Aid Measures

- Firefighting Measures

- Accidental Release Measures

- Handling and Storage

- Exposure Controls / Personal Protection

- Physical and Chemical Properties

- Stability and Reactivity

- Toxicological Information

- Ecological Information

- Disposal Considerations

- Transport Information

- Regulatory Information

Installation

Overview

Perma-Tread polymer stair treads are designed to minimize the expenses associated with stair fabrication, installation, and maintenance. The product matches nominal lumber sizes. These treads can be effortlessly machined on-site using standard tools, providing a hassle-free installation experience. Perma-Tread ensures a durable finish that remains impervious to rot or corrosion.

Common installation methods for interior or exterior stairs.

1. Entire stair is built with Perma-Tread

- Cut Perma-Tread 412 profile like 4 x 12 lumber.

- Utilize metal brackets to join stair stringers, stair treads, posts, and joists.

- Utilize lag screws or decking screws to fasten just like traditional wood stairs and treads.

- Benefit from a Perma-Tread stair system that will not corrode.

2. Metal stair with free spanning, open riser stair treads

- Cut Perma-Tread 412 profile like 4 x 12 lumber.

- Utilize metal stair stringers with seat angles to accept each stair tread.

- Utilize lag screws to fasten from underneath, just like wood stair treads or precast concrete stair treads.

- Benefit from a Perma-Tread stair system that will not corrode.

3. Metal stair with metal closed riser stair treads

- Cut Perma-Tread 212 profile like 2 x 12 lumber.

- Fabricate the stair structure with steel.

- Design closed riser metal stair treads to accept Perma-Tread.

- Use commercial adhesive to adhere Perma-Tread to the top face of the metal tread or use mechanical fasteners from underneath to attach.

- Benefit from a stair tread finish that will not corrode.

4. Metal stair with Perma-Tread stair treads and risers

- Cut Perma-Tread 212, 312, or 412 profile like lumber.

- Fabricate the stair structure with steel.

- Utilize metal stair stringers with special brackets to accept each Perma-Tread stair treads and risers.

- Utilize lag screws to fasten treads and risers from underneath.

- Benefit from a stair tread finish that will not corrode.

5. Stair landings and decks made with Perma-Tread

- Cut Perma-Tread 212 or other desired profile like lumber.

- Include ⅛” gap between decking boards.

- Install above support joists made from lumber or Perma-Tread.

- Utilize brackets and lag screws from underneath for a clean top finish.

- Utilize composite trim head self tapping composite deck screws to attach from top.

Maintenance

Overview

Perma-Tread polymer is a highly durable, impact resistant, non-absorbing, non-organic building product which requires minimal maintenance beyond normal surface washing when visibly required.

Care and Cleaning

Soap Wash

Spray deck and stair treads with soap, then follow by gently scrubbing each deck board with a soft bristle brush. Spray/rinse each individual deck board with cold, clear water. RINSE THOROUGHLY. If dirty water from cleaning is left to dry, a film will remain on the surface.

Remove Surface Dust

To remove surface dust, just wash with cold, clear water.

Pressure Wash

Spray/rinse each individual deck board using a fan tip no closer than 10-12 inches from the surface. It is not recommended to use more than 1,500psi.

Warranty

Overview

Perma-Tread precast polymer stair treads, planks, and decking are backed by a robust warranty, ensuring that your investment is protected against defects and premature wear. Perma-Tread is designed to have high quality and performance lasting for years to come.

Warranty summary

Perma-Tread products are guaranteed to last. All polymer products are warrantied for 1 year against manufacturer defects and 50 years against substantial defects directly caused by termite and fungal decay.

Please review the Perma-Tread Limited Product Warranty document for complete information.

Perma-Tread – Limited Product Warranty

National Stair Products is committed to delivering products of the highest quality and craftsmanship. We stand behind our workmanship and materials, and as such, we offer the following limited warranty.

(a) What this Limited Warranty Covers:

This Limited Warranty covers manufacture defects and substantial defects directly caused by termite and fungal decay as set forth below.

(b) How Long This Limited Warranty Lasts:

Subject to the terms and conditions of the Limited Product Warranty, National Stair Products (NSP) (hereinafter “Manufacturer,” “We” or “Us”) warrants to the original consumer (”Consumer” or “You” of NSP, (”Products”) that, manufactured defective product will be replaced for a period of one (1) year from the date of purchase, and in normal applications the Products will not splinter, crack, rot, decay, corrode, or suffer structural damage directly from termites or fungal decay under normal use for a period of (50) years from the date of purchase (the “Warranty Period”).

(c) What is Covered:

If the Products are found to be defective, We, in our sole discretion will promptly repair or replace the defective Products, or refund Your full purchase price for the Products only (excluding labor). Refunds if any will only apply to that portion of Products that are actually determined to be defective, regardless of the collective amount of Products or services purchased from Us or others.

(d) What is Not Covered:

Labor, installation and/or reinstallation, other associated costs, removal of Product, inspection, architect, contractor or engineer expenses, shipping, freight costs, fabrication, and time for on-site examination by others of proposed defects are not included with this limited warranty and shall not be paid by Us. This limited warranty only applies to Products directly manufactured by Us, which are returned to Us with transportation charges prepaid by You. Under no circumstances will We be responsible for ancillary costs and expenses incurred such as labor, removal, installation, re-installation, storage, time, freight or any other charge incurred by You, related to defective product. You are solely responsible for determining the suitability of use or application of any Product and whether Product meets the requirements of applicable building codes for specific applications. We do not warrant or guarantee, and You or your contractors are solely and exclusively responsible for determining (i) suitability of using Products in any particular application and/or design, and (ii) structural integrity and safety of all structures of any kind whatsoever constructed in whole or in part using Products. You and your contractor must review Manufacturer’s Product Specifications and consult with an architect, engineer, and other design professionals to determine suitability and applicability to local and/or national building and safety code regulations regarding all applications of Products.

We will have no warranty obligation with respect to the Product if any of the following events occur: (a) the Product is subjected to abuse, misuse, negligence, improper or abnormal use, failure to maintain, fire, or any accident including without limitation, acts of God, or environmental pollutants; (b) installation, storage, handling, fabrication, engineering, service, maintenance, or use of the Product which is not in accordance with the written installation requirements and/or is performed improperly, negligently, or by unqualified or unauthorized personnel or without competent supervision and as specified by Our literature, applicable laws regulations and industry standards (c) movement and/or collapse of the ground or structure on which the assemblage(s) incorporating the Product is installed (e) any variation of color, including but not limited to fading, discoloration and spotting (f) issues arising from expansion and contraction, nor any signs of static electricity of the Product as both are inherent to the Product (g) the Product is materially altered or modified (except if prior written approval of Manufacturer is obtained after the original installation); or (h) We have not received full payment for the invoice price of the order containing the warranted Product.

(e) How to Get Service:

To make a warranty claim under this Limited Product warranty, We shall receive from You (i) proof of date of purchase and purchase price, (ii) a photograph of the Product depicting the defect, (iii) a written description of claimed defects with name, address and contact information of the installer, if available. You shall send the warranty claim by mail within 30 days of discovering the claimed defect(s) to Attn: Warranty Claims Dept, National Stair Products, P.O. Box 9118 Brooks, OR 97305. No alterations or repair shall be made prior to the warranty claim. You shall give Us (or our agents) reasonable access to the property and location where the Products are located for inspection purposes and shall retain such Products for inspection.

(f) Exclusive Limited Warranty:

WE UNDERTAKE NO RESPONSIBILITY FOR THE QUALITY OF THE PRODUCTS EXCEPT AS OTHERWISE PROVIDED HEREIN. TO THE EXTENT PERMITTED BY LAW, OUR LIMITED PRODUCT WARRANTY AND THE REMEDIES SET FOR HEREIN ARE YOUR SOLE AND EXCLUSIVE REMEDY AND ARE OFFERED BY US IN LIEU OF ALL OTHER WARRANTIES, GUARANTEES AND/OR REMEDIES WHATSOEVER, INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR PURPOSE, OR OTHER WARRANTIES OR GUARANTEES ARISING BY OPERATION OF LAW, WHICH ARE HEREBY EXPRESSLY DISCLAIMED. WE ASSUME NO RESPONSIBILITY THAT THE PRODUCTS WILL BE FIT FOR ANY PARTICULAR PURPOSE FOR WHICH YOU MAY BE BUYING THE PRODUCTS, EXCEPT AS OTHERWISE PROVIDED HEREIN. TO THE EXTENT THE PRODUCTS ARE INSTALLED FOR CONSUMER APPLICATION, THE FOREGOING DISCLAIMERS MAY NOT APPLY. IN NO EVENT SHALL WE BE LIABLE TO PURCHASER OR THIRD PARTIES FOR SPECIAL, INCIDENTAL, CONSEQUENTIAL, PUNITIVE, ECONOMIC, EXEMPLARY OR OTHER SIMILAR DAMAGES.

(g) Limitation of Liability:

Purchaser agrees that Our entire liability, under any warranty, whether in contract, in tort, in negligence or otherwise shall not exceed the amount of the purchase price paid. UNDER NO CIRCUMSTANCES SHALL NATIONAL STAIR PRODUCTS BE LIABLE FOR CONSEQUENTIAL, SPECIAL OR INCIDENTAL DAMAGES, LOST PROFITS, LOSS OF BUSINESS OR ANY OTHER ECONOMIC DAMAGES. The price stated for the Product is based upon and in consideration for limiting Our liability. Neither Manufacturer nor its representatives approve, recommend, or perform design review for specific applications of the Product(s). No person or entity is authorized by Us to make, and We shall not be bound by any statement or representation as to the performance or Product other than what is contained in this Limited Warranty. This Limited Warranty shall not be amended or altered except in a written instrument signed by You and Us. ALL CLAIMS, CAUSES OF ACTION OR DEMANDS SHALL BE MADE WITHIN ONE (1) YEAR AFTER THE DEFECT IS DISCOVERED OR THE CLAIM OCCURRED. ALL CLAIMS OR CAUSES OF ACTION WITH RESPECT TO THE PRODUCTS SHALL EXCLUSIVELY BE ASSERTED IN A COURT OF COMPETENT JURISDICTION LOCATED IN SALEM, OREGON.

(h) How State Law Applies:

SOME STATES DO NOT ALLOW LIMITATIONS OF THE DURATION OF IMPLIED WARRANTIES OR THE EXCLUSIONS OR LIMITATIONS OF INCIDENTAL OR CONSEQUENTIAL DAMAGES. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU MAY HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STATE.

FAQs

When Perma-Tread polymer stair treads are fully supported by a proper support structure that is appropriately fire-rated. Perma-Tread is considered a finish material, making it an acceptable alternative to wood, carpet, vinyl, or rubber finishes. When Perma-Tread is fully exposed to flame, the building type must allow the use of combustible materials – polymer, plastic, rubber, vinyl, wood, composites, etc. materials are allowed. Building codes, building types, material fire-rating, and fire-rated assemblies determine the use of any building material. It is essential to consult with your code official before accepting any building material for specific use.

One of the most common ways people slip, trip, and fall is to lose balance when traveling up or down a flight of stairs. No matter how careful we are, anyone has the potential to slip and fall down a flight of stairs. Stair treads that are poorly built, become slick, have corroded, or have movement increase the chance of injury. Perma-Tread polymer stair treads resemble the durability of concrete and steel. In addition, the highly slip-resistant walking surface performs like rubber stair treads. Polymer stair treads are incredibly durable, even in the most extreme conditions. Perma-Tread is the safer stair tread ideal for the highest foot traffic and harshest conditions.

Contrary to popular belief, many polymers have high melting points and are designed to perform in harsh conditions. In other words, they can be exposed to high heat without compromising their mechanical properties. Perma-Tread is designed to exceed fire-ratings, making the product an acceptable alternative flooring building material when compared to wood, composites, vinyl, rubber, concrete, stone, tile, and more.

Perma-Tread polymer stair treads are designed to last 50+ years without manufacturing defects, which include becoming brittle. Perma-Tread will never warp, break, splinter, crack, shatter, rot, corrode, or decay when appropriately utilized.

Perma-Tread polymer stair treads can last virtually forever. The polymer has high toughness, strength, and fatigue resistance. The polymer can withstand wear and tear while remaining flexible enough to handle a hit. Our polymer recipe makes Perma-Tread an ideal solution for heavy use and harsh conditions.

Stair restoration or complete stair replacement is typical after years of wear and tear imposed on a stair system. Many stairs are originally built with wood, steel, and concrete, which rot or corrode over time. Perma-Tread polymer stair treads are the ideal replacement stair treads that will last a lifetime.

- Perma-Tread polymer stair treads are designed to last 50+ years without manufacturing defects. Perma-Tread polymer stair treads can last virtually forever.

- Perma-Tread polymer stair treads have high toughness, strength, and fatigue resistance. The polymer can withstand wear and tear while remaining flexible enough to handle a hit.

- Perma-Tread polymer stair treads can significantly reduce slip, trips, and falls because polymers naturally provide better grip, stability, durability, and aesthetics to buildings.

- Perma-Tread polymer stair treads are specially designed to exceed fire-ratings, making the product an acceptable alternative flooring building material compared to wood, composites, vinyl, rubber, concrete, stone, tile, and more.

Downloads Library

Overview

Download our current downloadable product resources. Contact us for questions.

- One Sheets

- Perma-Tread – Closed Riser Wood Stairs One Sheet

- Perma-Tread – Open Riser Metal Stairs One Sheet

- Perma-Tread – Open Riser Wood Stairs One Sheet

- Code Compliance & Testing

- Perma-Tread – ASTM E84 – A Rating Test Result

- Perma-Tread – ASTM E84 – B Rating Test Result

- Perma-Tread – ASTM E303 – Dry & Wet Test Result

- CAD Details

- Closed Riser Stair Plans

- Open Riser Stair Plans

- Detail Binder

Disclaimer: Information contained here is for informational purposes only. The information is not to be construed as endorsements or recommendation for its use. While National Stair Products believes the information contained herein is accurate to the best of our knowledge, National Stair Products makes no warranty, express or implied with respect to the accuracy or readability of this information. The product data is offered for your consideration, investigation and verification. Your building code official must approve for your intended use.