Sound Dampening For Metal Stair Treads

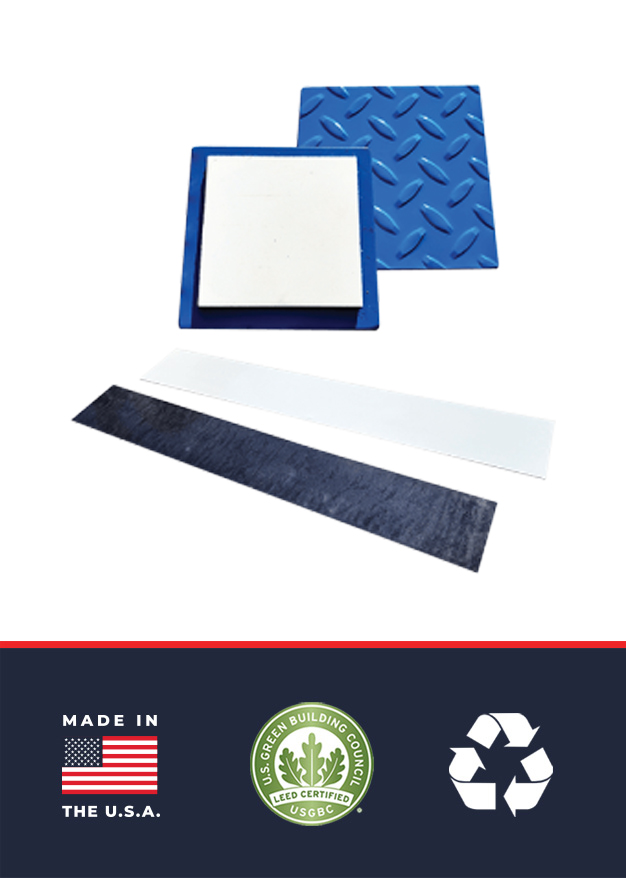

A peel and stick application applied to new or existing metal stairs.

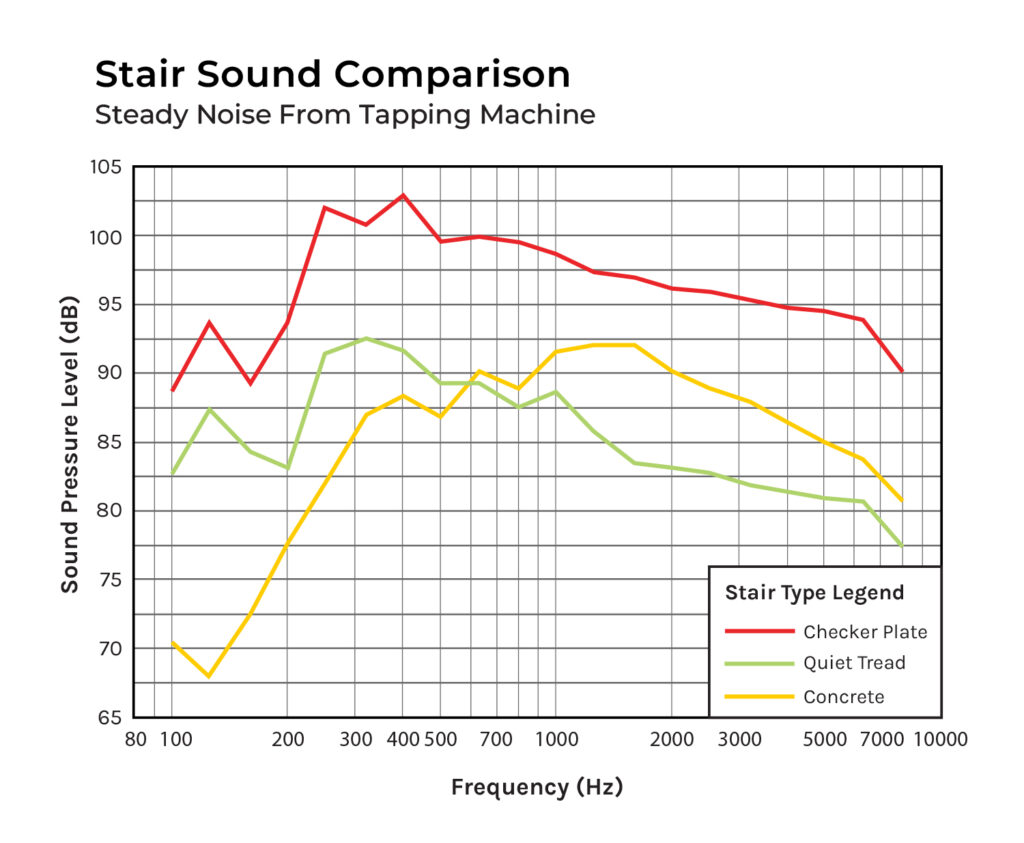

Sound Dampening For Loud Metal Diamond Plate Stairs

A revolutionary product designed to reduce noise levels commonly associated with normal foot traffic on checker plate diamond plate metal stairs and landings. Our proprietary testing reports that Quiet Tread® offers a steel stair system without the noise problem traditionally associated with checker plate stairs. A metal stair tread as quiet as concrete treads with normal foot traffic.

Download:

- Peel and Stick Application

- Panels Cut to Specification

- For 14 ga. 12 ga. 10 ga. ⅛” Diamond Plate Stairs

- ASTM E84 Class 1/A Fire Rating

- Acoustic Tested: ASTM E492-2004, ASTM E2235-2004, ISO 140.6-2006, ISO 3741-2006, IEC 61672

Product Information:

Click headings below for more information.

Applications

Overview

Quiet Tread was designed to reduce noise commonly associated with normal foot traffic on checker plate / diamond plate metal stairs. For new or existing applications, it is a solution to solve loud noise created by vibration from normal foot traffic. Quiet Tread makes steel stairs as quiet as concrete pan filled stairs.

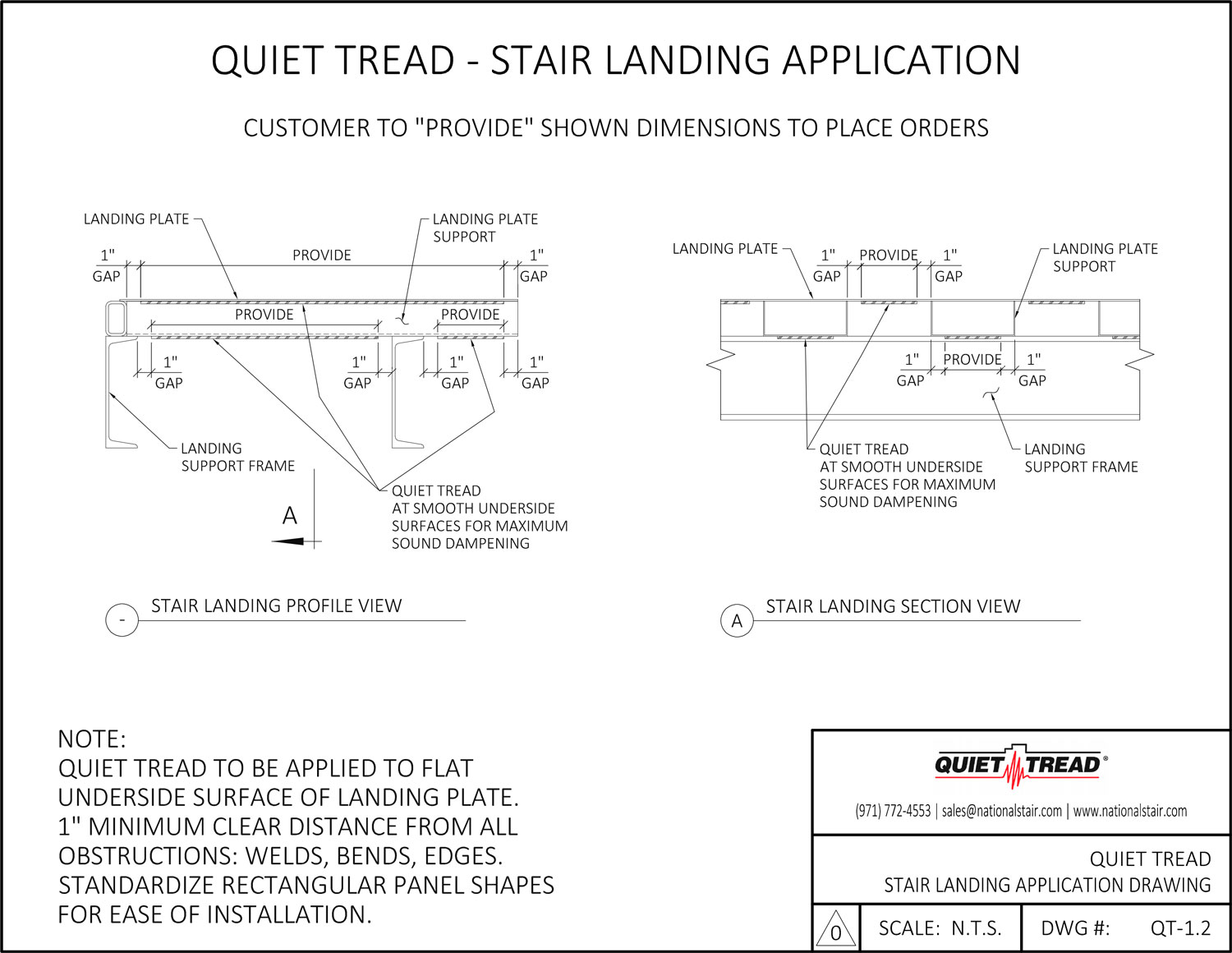

Important Note: Quiet Tread must be attached to a smooth, clean, dry surface. Each edge of Quiet Tread 1-2 inches away from obstructions, bends, and welds. This is to guarantee the best result and most coverage for absorbing the most vibration. The product must be applied completely flat for a lasting adhesive bond.

1. New Checker Plate / Diamond Plate Metal Stairs

- Product arrives pre-cut to specified dimensions.

- Product is applied to the underside of the tread and landing plate during stair fabrication.

- Peel and stick application before stairs are primer painted.

- Commonly installed on 14 ga., 12 ga., 10 ga., ⅛” metal plate.

- After install, the stairs are finished with paint for a clean appearance.

2. Existing Checker Plate / Diamond Plate Metal Stairs

- Product arrives pre-cut to specified dimensions.

- Product is applied to the underside of the tread and landing plate on site.

- The stair tread surfaces which will accept Quiet Tread must be carefully inspected, prepared, and thoroughly cleaned for a lasting bond.

- Peel and stick application onto existing stairs.

- Commonly installed on 14 ga., 12 ga., 10 ga., ⅛” metal plate.

- After install, the stairs are finished with paint for a clean appearance.

Products

Overview

Quiet Tread is a peel and stick sheet made from a proprietary sound dampening mat with adhesive pre-applied. The outer face is finished with a metal sheet to accept finish paint and protect the assembly for fire-rating.

Important Note: Quiet Tread must be attached to a smooth, clean, dry surface. Each edge of Quiet Tread 1-2 inches away from obstructions, bends, and welds. This is to guarantee the best result and most coverage for absorbing the most vibration. The product must be applied completely flat for a lasting adhesive bond.

STOCK SHEET (CUT BY OTHERS)

Width x Length x Thickness

- 60 inch x 120 inch x 0.125 inch

Pre Cut For Stair Treads

Width x Length x Thickness

- 9, 7.5, 6, 5, 4, 3 inch x 34 inch x 0.125 inch

- 9, 7.5, 6, 5, 4, 3 inch x 38 inch x 0.125 inch

- 9, 7.5, 6, 5, 4, 3 inch x 42 inch x 0.125 inch

- 9, 7.5, 6, 5, 4, 3 inch x 46 inch x 0.125 inch

- 9, 7.5, 6, 5, 4, 3 inch x 50 inch x 0.125 inch

- 9, 7.5, 6, 5, 4, 3 inch x 54 inch x 0.125 inch

- 9, 7.5, 6, 5, 4, 3 inch x 58 inch x 0.125 inch

Pre Cut For Landings

Width x Length x Thickness

- 48, 36, 24, 12, 10, 9, 8, 7, 6, 5, 4, 3 inch x 34 inch x 0.125 inch

- 48, 36, 24, 12, 10, 9, 8, 7, 6, 5, 4, 3 inch x 38 inch x 0.125 inch

- 48, 36, 24, 12, 10, 9, 8, 7, 6, 5, 4, 3 inch x 42 inch x 0.125 inch

- 48, 36, 24, 12, 10, 9, 8, 7, 6, 5, 4, 3 inch x 46 inch x 0.125 inch

- 48, 36, 24, 12, 10, 9, 8, 7, 6, 5, 4, 3 inch x 50 inch x 0.125 inch

- 48, 36, 24, 12, 10, 9, 8, 7, 6, 5, 4, 3 inch x 54 inch x 0.125 inch

- 48, 36, 24, 12, 10, 9, 8, 7, 6, 5, 4, 3 inch x 58 inch x 0.125 inch

Pre Cut Custom Rectangles

- Contact us for custom pre-cut panels. Shapes no larger than 120 inch x 60 inch.

Colors

Overview

Quiet Tread arrives with the outer face finish painted white. This serves as a primer for accepting the final finish paint. Quiet Tread is painted over to match the metal stair, landing, and railing finish.

STANDARD COLORS:

Disclaimer: Actual color may vary between monitors and printers. Due to the manufacturing process, slight variations of color and texture will occur.

Benefits

Overview

The Problem: Checker Plate and Diamond Plate Metal Stairs offer an instant finished stair system. Requiring no on-site finish work to complete the walking surface. Unfortunately walking on metal only stairs creates vibration and this creates sound. That sound creates a major acoustics problem for high foot traffic stairs and a nuisance to occupants and tenants on the other side of the wall.

REMOVES SOUND COMMONLY ASSOCIATED WITH METAL STAIRS

The peel and stick mat absorbs the vibrations created by foot traffic to dampen the sound.

ALLOWS FABRICATORS TO BUILD STAIRS WITH THIN GAUGE METAL

Thicker tread plates vibrate less, however, it is costly, difficult to fabricate, and heavy. Fabricating with thinner materials offers many efficiencies; lighter stairs systems impose less weight on the building structure which offers cost savings beyond the stair system.

OFFERS ARCHITECTS, BUILDING OWNERS, CONTRACTORS COST SAVINGS

Checker plate or diamond plate stairs offer an instant finish and are most affordable to fabricate and install. However, the associated sound issue is the most common reason for stairs built using concrete or other finishes. Quiet Tread is often shop applied and resolves the sound issue immediately. The stairs are installed and are immediately ready for use. No additional trades, temporary infills, or on site finishing required.

ELIMINATES THE NEED TO BUILD WITH COSTLY PAN FILLED STAIRS

Pan filled stairs are often selected because concrete solves the sound issue. However, concrete comes at a cost: site labor, site pour, site cleanup, scheduling delays, concrete cracking, poor finish, concrete corrosion issues.

AN INSTANT APPLICATION AND STAIR SOUND DAMPENING SOLUTION

Quiet Tread was created to solve the noise issue immediately for the least amount of ownership overall cost. It is a simple peel and stick application to the underside of the walking surface, and requires minimal preparation, labor, and zero maintenance after installation. Eliminating on-site time, labor, and various trades outweighs the Quiet Tread investment.

Images

Overview

View Quiet Tread images – showcasing product material, installation, and final install.

Images

Videos

Overview

Watch our Quiet Tread videos – demonstrating diamond plate stairs with and without Quiet Tread, plus Sound Testing footage.

Without Quiet Tread | 00:05

Advantages of Quiet Tread

With Quiet Tread | 00:04

Advantages of Quiet Tread

ASTM Testing Videos

Baseline Sound Testing | 00:13

Concrete Filled Pan Stairs

Baseline Sound Testing | 00:13

Steel Checkered Plate Stairs

Sound Testing | 00:13

Proprietary use of Line-XTM

Quiet Tread Sound Testing | 00:13

Step Only

Quiet Tread Sound Testing | 00:15

Riser Only

Quiet Tread Sound Testing | 00:13

Step and Riser

Drawings

Overview

Discover our comprehensive design details for Quiet Tread application, for both stairs and landings.

ASTM Testing

Overview

The following information describes the technical ASTM acoustics testing performed on prefabricated metal stairs. Testing was conducted to compare sound levels commonly associated with metal stairs. The Quiet Tread application was compared to traditional checker plate / diamond plate metal stairs, concrete pan filled metal stairs, and spray on acoustic applications.

Related Videos

Quiet Tread Sound Testing | 00:13

Step Only

Quiet Tread Sound Testing | 00:15

Riser Only

Quiet Tread Sound Testing | 00:13

Step and Riser

Comparison Sound Testing | 00:13

Concrete Filled Pan Stairs

Comparison Sound Testing | 00:13

Steel Checkered Plate Stairs

Comparison Sound Testing | 00:13

Proprietary use of Line-X™

Quiet Tread Peak Sound Test Results

Quiet Tread vs. Traditional Concrete Filled Metal Pan

When applied to the step only, Quiet Tread’s sound dampening is comparable to traditional concrete filled stair pans on prefabricated steel stairs.

| Normal Walking On Stairs Alone Test | Hammer Drop On Stairs Alone Test | Hammer Drop On Stairs Connected to Landing Test | Hammer Drop On Landings Connected to Stairs Test | |

|---|---|---|---|---|

| Bare Diamond / Checker Plate Stair Treads | 98.7 dB | 122.7 dB | 124.0 dB | 127.1 dB |

| Quiet Tread Applied to Stair Tread Only | 89.4 dB | 115.4 dB | 113.0 dB | 120.8 dB |

| Quiet Tread Applied to Stair Riser and Tread | 88.5 dB | 116.5 dB | 112.4 dB | 120.6 dB |

| Quiet Tread Applied to Stair Riser Only | 89.7 dB | 120.7 dB | 121.4 dB | 124.0 dB |

| Concrete Filled Metal Pan | 85.5 dB | 115.5 dB | Not Tested | Not Tested |

| Line-X (Spray Coating) | 90.8 dB | 119.4 dB | 119.7 dB | 125.3 dB |

Background

Prefabricated steel stair assemblies are commonly used in industrial, commercial, and residential applications. In some situations, stairways can be a source of noise that can adversely affect the comfort of occupants in adjacent areas. Generally, steel stairs with concrete filled pans have been considered quieter than steel tread covered stairs. However, concrete filled pans are more expensive, must be protected during construction, and can require remediation if cracked or damaged before occupancy. The purpose of the present research was to quantify the relative acoustic performance of different stair treatments under different mechanical inputs. Six different stair treatments were investigated. These included:

- Traditional concrete filled pan stairs

- Traditional steel checkered plate stairs

- Steel checkered plate stairs with proprietary use of Line-X™

- Steel checkered plate stairs with proprietary use of Quiet Tread applied to risers alone

- Steel checkered plate stairs with proprietary use of Quiet Tread applied to steps alone

- Steel checkered plate stairs with proprietary use of Quiet Tread applied to steps and risers

These six single flights of stairs were tested individually and then five were tested with accompanying landings. All stair assemblies were fabricated by the Pacific Stair Corporation with production-run details and materials. The traditional stairs (checkered plate and concrete filled pans) provide the current reference acoustic performance baseline levels. In addition to the individual flights, three landings (one checkered plate, one Quiet Tread, and one Line-X™) were tested in combination with their matching stair flights.

No standardized acoustic testing protocols exist for stair assemblies and national and international standards, including ASTM, ISO 140, British and Australian Standards were surveyed and adapted to develop acoustical performance tests of stairs and stair assemblies. Testing protocols were adapted from the following standards as they apply to this research:

- ASTM E 492-04: Standard Test Method for Laboratory Measurement of Impact Sound Transmission through Floor-Ceiling Assemblies Using the Tapping Machine

- ASTM E 2235-04: Standard Test Method for Determination of Decay Rates for Use in Sound Insulation Test Methods

- ISO 140.6-2006: Acoustics – Measurement of Sound insulation in buildings and of building elements. Part 6: Laboratory measurements of impact sound insulation of floors.

- ISO 3741: Acoustics – Determination of sound power levels of noise sources using sound pressure – Precision methods for reverberation rooms

Reverberation Chamber Description and Acoustic Characteristics

A reverberation chamber was constructed to test the acoustic performance of the stair assemblies. The chamber was designed to reject background noise, allow acoustic reverberations (exhibit low acoustic absorption), and to simulate the geometric conditions of use for prefabricated steel stairs (representative of a stairwell). The chamber floor was a cast-in-place concrete slab and j-bolts were installed to allow attachment of the stair landings. The walls and roof were wood framed with 2×6 lumber and sheathed in ¾ in. thick MDO plywood. Fiberglass insulation was placed between the studs.

Epoxy paint was applied to the sheathing to produce a hard surface. As suggested in ASTM E 492, sound diffusion panels employed in order to create a more diffuse sound field within the chamber. Two diffusing panels, also made of ¾” MDO, were hung from the ceiling of the chamber. The inside plan dimensions of the final room were 105 in. by 125 in. and the chamber was 144 in. tall. These dimensions meet the requirements of ASTM E 492 that dimensions not be ratios of small whole numbers and that the ratio of the largest dimension to the smallest be less than two. The total volume of the room was 1094 cubic feet.

Disclaimer: Information contained here is taken from information provided by the suppliers of our raw materials and third-party test facilities. While National Stair Products believes the information contained herein is accurate to the best of our knowledge, National Stair Products makes no warranty, express or implied with respect to the accuracy or readability of this information. This data is offered for your consideration, investigation and verification.

Technical Data

Overview

The following information describes the technical characteristics of Quiet Tread. Made from a high density viscoelastic copolymer material with a metal outer coat and peel and stick backing. The final product offers a class A fire rating result. Quiet Tread reduces noise by taking impact vibration and structure borne noises and transfers the vibration into friction. The absorbed vibration then reduces generated sound.

Quiet Tread Technical Data

Quiet Tread Dimensions

| Value | |

|---|---|

| Thickness | 0.125” |

| Max Width | 60” |

| Max Length | 120″ |

| Weight | 1.8 Lbs. / Sq. Ft. |

Quiet Tread Fire Rating

| Flame Spread Index | Smoke Developed Index | Class Rating | |

|---|---|---|---|

| ASTM E84 | 10 | 55 | Class 1 or A |

Quiet Tread Peak Sound Test Results

Quiet Tread vs. Traditional Concrete Filled Metal Pan

When applied to the step only, Quiet Tread’s sound dampening is comparable to traditional concrete filled stair pans on prefabricated steel stairs.

| Normal Walking On Stairs Alone Test | Hammer Drop On Stairs Alone Test | Hammer Drop On Stairs Connected to Landing Test | Hammer Drop On Landings Connected to Stairs Test | |

|---|---|---|---|---|

| Bare Diamond / Checker Plate Stair Treads | 98.7 dB | 122.7 dB | 124.0 dB | 127.1 dB |

| Quiet Tread Applied to Stair Tread Only | 89.4 dB | 115.4 dB | 113.0 dB | 120.8 dB |

| Quiet Tread Applied to Stair Riser and Tread | 88.5 dB | 116.5 dB | 112.4 dB | 120.6 dB |

| Quiet Tread Applied to Stair Riser Only | 89.7 dB | 120.7 dB | 121.4 dB | 124.0 dB |

| Concrete Filled Metal Pan | 85.5 dB | 115.5 dB | Not Tested | Not Tested |

| Line-X (Spray Coating) | 90.8 dB | 119.4 dB | 119.7 dB | 125.3 dB |

Disclaimer: Information contained in this TDS is taken from information provided by the suppliers of our raw materials and third-party test facilities. While National Stair Products believes the information contained herein is accurate to the best of our knowledge, National Stair Products makes no warranty, express or implied with respect to the accuracy or readability of this information. This data is offered for your consideration, investigation and verification.

Installation

Overview

Quiet Tread is a peel and stick application to the underside of stair treads and landings where foot traffic occurs. Quiet Tread must be attached to a smooth, clean, dry surface. Each edge of Quiet Tread 1-2 inches away from edges, obstructions, bends, and welds. This is to guarantee the best result, the most coverage for absorbing the most vibration to reduce sound. The product must be applied completely flat for a lasting adhesive bond.

INSTALL SHOP APPLIED DURING STAIR FABRICATION

- Important Information

- Install Quiet Tread on the unfinished underside of the metal stair tread and landing sheet.

- Inspect the stair treads or landing sheet to ensure the underside surface is smooth and free from imperfections.

- Clean and dry the surface of the stair treads or landing sheet that will receive Quiet Tread, ensuring it is free of loose mill scale, imperfections, rust, dust, moisture, solvents, or oils. The manufacturer recommends using 99% alcohol and white cloth which does not leave loose threads for cleaning.

- It is crucial that the surface is thoroughly cleaned, as adhesive bond failure can occur if not. Additionally, ensure the metal stair tread substrate is flat.

- Remember, the quality of the adhesive depends on the surface it adheres to, so correct any imperfections before proceeding with the installation.

- Install Preparation

- Begin by placing the prefabricated stair flights and landings upside down on the floor in a protected interior environment to prevent any contamination during the cleaning process.

- Ensure that the ambient temperature of the installation environment and the surface temperature of the metal fall within the range of 70°F to 120°F. If necessary, use a propane torch to heat the metal surfaces to achieve the desired temperature.

- Thoroughly clean the surfaces where the Quiet Tread will be applied. To ensure proper cleanliness, use a new cloth to verify that the surfaces are completely free of any debris or contaminants.

- Plan out the layout with markings on the steel for installing the Quiet Tread panels. Once the panel is applied onto the substrate, it cannot be moved or removed without causing irreparable damage to the Quiet Tread panel. Therefore, careful planning and precision during installation is crucial.

- Apply Quiet Tread

- Ensure all installation preparations are complete before proceeding.

- Remove the release backing from the underside of the Quiet Tread panel.

- With the assistance of another worker, position one corner of the Quiet Tread panel on the layout mark, aligning the panel with the edge of the stair tread and maintaining a distance of 1 inch from the edge.

- Starting from one end of the panel, gradually lower it onto the underside of the tread surface, taking care to avoid trapping air between the substrate and the Quiet Tread panel.

- Once the Quiet Tread panel is in position, firmly press down with hands to eliminate any air pockets.

- Applying Pressure For Adhesive Bond

- Using a commercial-grade vinyl roller. Start by rolling the panel onto the underside of the stair tread substrate from one end to the other, applying approximately 25 lbs. per square inch pressure.

- After completing the first pass, rotate the roller 90 degrees, and repeat rolling the Quiet Tread panel using ~25 lbs. per square inch.

- Proper attachment of the Quiet Tread panel to the smooth metal substrate is crucial. Make sure to roll it thoroughly to maximize the bond between the stair tread substrate and the Quiet Tread panel. The roller is used in both up-and-down and side-to-side directions.

- Cure Time

- Allow 1 hour for the adhesive to set before moving the stair into the outside environment.

- Keep the stairs dry.

- Allow 24 hours for the adhesive bond to cure.

- Finish Painting

- After the cure time, simply prime or paint the stairs and landings. No further steps are necessary.

FIELD INSTALL ON EXISTING STAIRS

Quiet Tread can be applied to existing stairs with proper preparation and installation techniques. Follow the standard steps for installing on new stairs but take extra care to ensure a strong bond.

- Surface Condition Check

- Ensure the underside substrate of the stair tread or landing is free from rust or corrosion.

- Verify that any pre-applied finish won’t peel or flake once the Quiet Tread panel is installed.

- If there are concerns, sand the substrate surface which Quiet Tread would be adhered to and clean it thoroughly before installation.

- Installation Preparations

- Install Quiet Tread panels using scaffolding underneath the stairs.

- Plan labor, occupant egress, and necessary equipment ahead of time.

- Layout Markings

- Make precise layout markings to avoid improper placement and ensure consistent application.

- Application Technique:

- Apply pressure with a commercial-grade vinyl roller immediately after placing Quiet Tread.

- Repeat rolling one hour later to ensure the bond remains intact due to gravity.

- Final Touches

- Allow 24 hours for the adhesive bond to cure.

- Visually inspect panels to ensure the bond remained intact due to gravity.

- Finish paint over the Quiet Tread panels.

- Pay special attention to sealing exposed edges with paint to protect the adhesive bond from contaminants.

Maintenance

Overview

With proper installation of Quiet Tread and regular inspection, minimal to no maintenance is required.

CARE

- Avoid using salts, deicers, or chemicals on stairs, as they can cause metal stairs to rust or corrode, thereby compromising the Quiet Tread adhesive bond.

- Stairs exposed to the elements, moisture, or water may weaken the adhesive bond.

- After installation, it is advisable to apply a finishing coat of paint to the stair system or structure where Quiet Tread has been installed. This finishing paint helps shield Quiet Tread from moisture, liquid, rust, dust, grime, or tampering by encapsulating its exposed edges and surface.

- In areas where moisture, liquid, and rust are potential issues, it’s strongly advised to protect Quiet Tread by applying a durable finish coat of paint or another suitable finish. Regularly inspect and touch up the finish coat to prevent contamination between the surface accepting Quiet Tread and its adhesive surface.

- It’s advisable to conduct regular inspections for delamination in areas where Quiet Tread is installed. In case of any concerns, reach out to National Stair Products on a case-by-case basis to address potential delamination problems before they escalate into significant failures.

CLEANING

Follow these steps to clean the underside surface of metal stairs and prevent corrosion or rust after installation of Quiet Tread.

- Remove Debris: Start by removing any dirt, dust, or debris from the surface using a stiff brush or broom.

- Use Mild Detergent: Mix a mild detergent with warm water. Apply the solution to the underside surface of the metal stairs using a sponge or cloth. Gently scrub the surface to remove any remaining dirt or grime.

- Rinse Thoroughly: Rinse the surface thoroughly with clean water to remove any traces of detergent. Make sure to rinse away all soap residue.

- Dry Completely: Use a clean towel or cloth to dry the surface completely. Ensure that there is no moisture left on the metal stairs, as standing water can promote corrosion.

- Apply Protective Coating: Optionally, consider applying a protective coating or sealant specifically designed for metal surfaces. This can help create a barrier against moisture and prevent corrosion over time.

- Regular Maintenance: Schedule regular inspections and cleaning sessions to keep the underside surface of the metal stairs clean and free from corrosion. Promptly address any signs of rust or corrosion by cleaning and applying appropriate treatments.

STORAGE

- Stack flat. Do not Lean.

- Do not remove from factory packaging.

- Store indoors in a temperature controlled environment.

- Do not expose to moisture.

- Keep away from heat sources.

Warranty

Overview

Quiet Tread is backed by a warranty against defects in manufacturing, materials, and workmanship. For optimal performance and longevity, it is crucial to adhere to proper installation procedures, perform regular maintenance, and conduct routine inspections.

Warranty Summary

National Stair Products (“NSP”) warrants to the original purchaser (“Customer”) that Quiet Tread products (“Products”) will be free from defects in manufacturing, materials and workmanship for a period of one year from the date of purchase.

Please review the Quiet Tread Limited Product Warranty document for complete information.

Quiet Tread – Limited Product Warranty

National Stair Products is committed to delivering products of the highest quality and craftsmanship. We stand behind our workmanship and materials, and as such, we offer the following limited warranty.

(a) What this Limited Warranty Covers:

This Limited Warranty covers manufacture defects and substantial defects directly caused by workmanship and materials.

(b) How Long This Limited Warranty Lasts:

Subject to the terms and conditions of the Limited Product Warranty, National Stair Products (NSP) (hereinafter “Manufacturer,” “We” or “Us”) warrants to the original consumer (”Consumer” or “You” of NSP, (”Products”) that, manufactured defective product will be replaced for a period of one (1) year from the date of purchase, and in proper install applications the Products material layers, which make up the panel, will not separate during this period when properly installed for normal use interior applications.

(c) What is Covered:

If the Products are found to be defective, We, in our sole discretion will promptly repair or replace the defective Products, or refund Your full purchase price for the Products only (excluding labor). Refunds if any will only apply to that portion of Products that are actually determined to be defective, regardless of the collective amount of Products or services purchased from Us or others.

(d) What is Not Covered:

Labor, installation and/or reinstallation, other associated costs, removal of Product, inspection, architect, contractor or engineer expenses, shipping, freight costs, fabrication, and time for on-site examination by others of proposed defects are not included with this limited warranty and shall not be paid by Us. This limited warranty only applies to Products directly manufactured by Us, which are returned to Us with transportation charges prepaid by You. Under no circumstances will We be responsible for ancillary costs and expenses incurred such as labor, removal, installation, re-installation, storage, time, freight or any other charge incurred by You, related to defective product. You are solely responsible for determining the suitability of use or application of any Product and whether Product meets the requirements of applicable building codes for specific applications. We do not warrant or guarantee, and You or your contractors are solely and exclusively responsible for determining (i) suitability of using Products in any particular application and/or design, and (ii) structural integrity and safety of all structures of any kind whatsoever constructed in whole or in part using Products. You and your contractor must review Manufacturer’s Product Specifications and consult with an architect, engineer, and other design professionals to determine suitability and applicability to local and/or national building and safety code regulations regarding all applications of Products.

We will have no warranty obligation with respect to the Product if any of the following events occur: (a) the Product is subjected to abuse, misuse, negligence, improper or abnormal use, failure to maintain, fire, or any accident including without limitation, acts of God, or environmental pollutants; (b) installation, storage, handling, fabrication, engineering, service, maintenance, or use of the Product which is not in accordance with the written installation requirements and/or is performed improperly, negligently, or by unqualified or unauthorized personnel or without competent supervision and as specified by Our literature, applicable laws regulations and industry standards (c) issues arising from expansion and contraction of subsurface where Product is applied (d) the Product is materially altered or modified (except if prior written approval of Manufacturer is obtained after the original installation); or (e) We have not received full payment for the invoice price of the order containing the warranted Product.

(e) How to Get Service:

To make a warranty claim under this Limited Product warranty, We shall receive from You (i) proof of date of purchase and purchase price, (ii) a photograph of the Product depicting the defect, (iii) a written description of claimed defects with name, address and contact information of the installer, if available. You shall send the warranty claim by mail within 30 days of discovering the claimed defect(s) to Attn: Warranty Claims Dept, National Stair Products, P.O. Box 9118 Brooks, OR 97305. No alterations or repair shall be made prior to the warranty claim. You shall give Us (or our agents) reasonable access to the property and location where the Products are located for inspection purposes and shall retain such Products for inspection.

(f) Exclusive Limited Warranty:

WE UNDERTAKE NO RESPONSIBILITY FOR THE QUALITY OF THE PRODUCTS EXCEPT AS OTHERWISE PROVIDED HEREIN. TO THE EXTENT PERMITTED BY LAW, OUR LIMITED PRODUCT WARRANTY AND THE REMEDIES SET FOR HEREIN ARE YOUR SOLE AND EXCLUSIVE REMEDY AND ARE OFFERED BY US IN LIEU OF ALL OTHER WARRANTIES, GUARANTEES AND/OR REMEDIES WHATSOEVER, INCLUDING BUT NOT LIMITED TO IMPLIED WARRANTIES OF MERCHANTABILITY AND/OR FITNESS FOR A PARTICULAR PURPOSE, OR OTHER WARRANTIES OR GUARANTEES ARISING BY OPERATION OF LAW, WHICH ARE HEREBY EXPRESSLY DISCLAIMED. WE ASSUME NO RESPONSIBILITY THAT THE PRODUCTS WILL BE FIT FOR ANY PARTICULAR PURPOSE FOR WHICH YOU MAY BE BUYING THE PRODUCTS, EXCEPT AS OTHERWISE PROVIDED HEREIN. TO THE EXTENT THE PRODUCTS ARE INSTALLED FOR CONSUMER APPLICATION, THE FOREGOING DISCLAIMERS MAY NOT APPLY. IN NO EVENT SHALL WE BE LIABLE TO PURCHASER OR THIRD PARTIES FOR SPECIAL, INCIDENTAL, CONSEQUENTIAL, PUNITIVE, ECONOMIC, EXEMPLARY OR OTHER SIMILAR DAMAGES.

(g) Limitation of Liability:

Purchaser agrees that Our entire liability, under any warranty, whether in contract, in tort, in negligence or otherwise shall not exceed the amount of the purchase price paid. UNDER NO CIRCUMSTANCES SHALL NATIONAL STAIR PRODUCTS BE LIABLE FOR CONSEQUENTIAL, SPECIAL OR INCIDENTAL DAMAGES, LOST PROFITS, LOSS OF BUSINESS OR ANY OTHER ECONOMIC DAMAGES. The price stated for the Product is based upon and in consideration for limiting Our liability. Neither Manufacturer nor its representatives approve, recommend, or perform design review for specific applications of the Product(s). No person or entity is authorized by Us to make, and We shall not be bound by any statement or representation as to the performance or Product other than what is contained in this Limited Warranty. This Limited Warranty shall not be amended or altered except in a written instrument signed by You and Us. ALL CLAIMS, CAUSES OF ACTION OR DEMANDS SHALL BE MADE WITHIN ONE (1) YEAR AFTER THE DEFECT IS DISCOVERED OR THE CLAIM OCCURRED. ALL CLAIMS OR CAUSES OF ACTION WITH RESPECT TO THE PRODUCTS SHALL EXCLUSIVELY BE ASSERTED IN A COURT OF COMPETENT JURISDICTION LOCATED IN SALEM, OREGON.

(h) How State Law Applies:

SOME STATES DO NOT ALLOW LIMITATIONS OF THE DURATION OF IMPLIED WARRANTIES OR THE EXCLUSIONS OR LIMITATIONS OF INCIDENTAL OR CONSEQUENTIAL DAMAGES. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS AND YOU MAY HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STATE.

ADDITIONAL WARRANTY INFORMATION:

This warranty does not apply where:

- Product has been abused, misused, or improperly installed.

- Alterations have been made to the product.

- Regular maintenance instructions are neglected.

FOR YOUR PROTECTION

The carrier who delivers merchandise to your door or job site is responsible for loss and damages. Acceptance of the shipment by the transportation company is acknowledgment that the articles delivered were in good condition and properly packed.

CONCEALED DAMAGE

If damage is noticed when merchandise is unpackaged, notify the transportation company’s office immediately and ask to have it inspected. Do not destroy packing materials until shipment is inspected and claims settled.

All claims or loss or damage should be filed immediately with the transportation company making delivery to your door or job site, then notify National Stair Products. We will mark our records accordingly. Should you need assistance with the claims we will be glad to help.

Note: Do not reject or return damaged merchandise to the transportation company. The transportation company will pick up after settling the claims.

IMPORTANT: RETURN GOODS CANNOT BE RETURNED WITHOUT WRITTEN AUTHORITY

Call or email National Stair Products for return authorization number (RMA). All shipments not having this number will be refused. All shipments returned for credit or exchange when the error is not ours will be subject to the following:

- 15% restocking charge, and

- Material must be returned – shipping prepaid by customer.

Downloads Library

Overview

Download our current product resources. Contact us for questions.

Disclaimer: Information contained here is for informational purposes only. The information is not to be construed as endorsements or recommendation for its use. While National Stair Products believes the information contained herein is accurate to the best of our knowledge, National Stair Products makes no warranty, express or implied with respect to the accuracy or readability of this information. The product data is offered for your consideration, investigation and verification. Your building code official must approve for your intended use.