Metal Stair Treads & Stair Pans

Your supplier of pre-fabricated metal stair treads and metal stair pans for new and restoration stair projects.

We manufacture Metal Stair Treads and Stair Pans To Exact Spec.

Supplying metal fabrication shops, contractors and builders who do not have the in-house means or machinery to fabricate their own metal stair treads, risers and pans.

We utilize our network of regional fabrication partners who have the experience. Working to provide the best lead times, prices and accuracy.

Offering many styles, base materials and finishes to match the architectural design required.

Download:

- Flat pan stair treads

- Pan filled stair treads

- Checker / diamond plate treads

- Grating stair treads

- Tread riser closures

Product Information:

Click headings below for more information.

Applications

Overview

Metal stair treads and stair pans serve specific purposes in the construction and functionality of staircases, particularly in commercial, industrial, and some residential settings.

1. Metal Stair Treads

Durability and Strength:

- Metal stair treads are designed to withstand heavy foot traffic and harsh conditions, making them ideal for industrial and commercial applications.

- They are often made from steel, known for their high strength-to-weight ratio and resistance to wear and tear.

Safety:

- Metal stair treads typically feature non-slip surfaces, such as diamond plate patterns or serrated edges, to provide traction and reduce the risk of slips and falls.

- They can also include nosings (the front edge of the tread) with anti-slip properties to enhance safety further.

Low Maintenance:

- Metal treads are relatively easy to clean and maintain compared to wood or other materials, making them practical for environments where hygiene and cleanliness are crucial.

- They are resistant to damage from chemicals, spills, and other potential contaminants.

Fire Resistance:

- Metal does not burn, making metal stair treads a safer option in terms of fire safety compared to wooden treads.

Aesthetic Options:

- Metal stair treads can be finished in various ways, including painting, powder coating, or galvanizing, to suit the aesthetic requirements of different spaces.

2. METAL STAIR PANS

Structural Support:

- Stair pans (also known as pan stairs or tread pans) are typically used in the construction of concrete-filled stairs.

- They provide a framework or mold into which concrete is poured, forming the actual tread surface once it hardens.

- This combination of metal and concrete provides a robust and durable stair solution.

- Flat pans provide a support structure for accepting final finish materials such as precast treads, stone, tile, carpet, wood, or rubber finishes.

Ease of Construction:

- Using stair pans simplifies the construction process by providing a ready-made falt surface for finish materials or a form for concrete pours, ensuring uniformity and reducing labor time.

- They can be easily integrated into the stair stringers (the side supports of the stairs).

Customization:

- Stair pans can be fabricated in various sizes and depths to accommodate different architectural requirements and design preferences.

- They can be customized with additional features like riser plates, nosings, and finishes.

Fire Safety:

- Similar to metal stair treads, stair pans contribute to the fire resistance of the staircase, particularly important in commercial and industrial buildings.

Drawings

Overview

Metal Stair Treads and Metal Stair Pans are available in standard shapes and sizes or fabricated to customer specifications. Includes the starter riser, tread and riser, and the top riser. Shipped ready to weld to stair stringers in the fabrication shop or on the job site.

Products

Overview

Metal Stair Treads and Metal Stair Pans are available in standard shapes and sizes or custom fabricated to customer specifications. Includes the starter riser, typical intermediate treads and riser, and the top riser. Shipped ready to weld (or bolt when applicable) to stair stringers in the fabrication shop or on the job site.

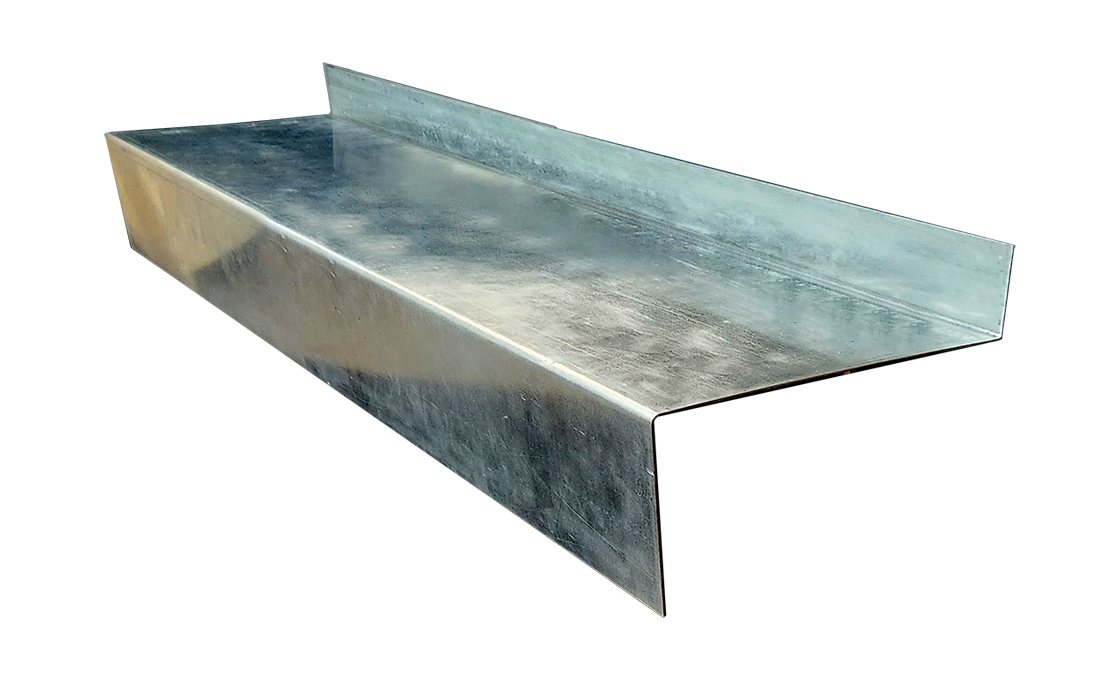

| Universal Flat Pan | Model # | Description |

|---|---|---|

|

P-1A |

|

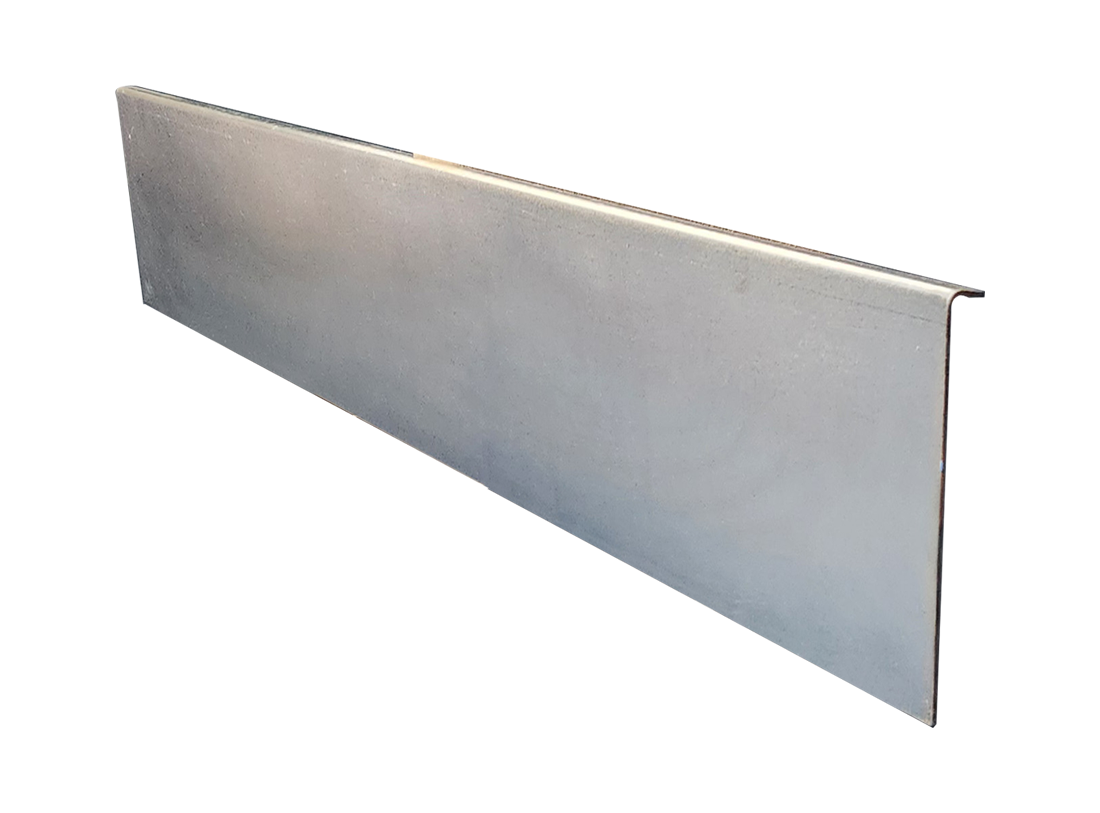

| Universal Riser Closure | Model # | Description |

|---|---|---|

|

P-2A |

|

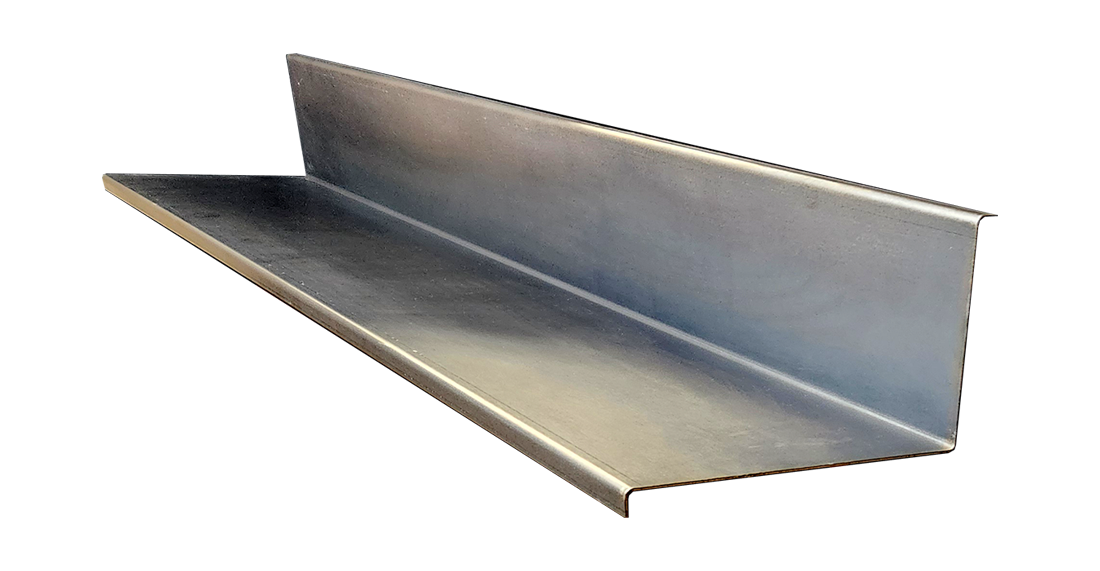

| Concrete Filled Stair Pan | Model # | Description |

|---|---|---|

|

P-3A |

|

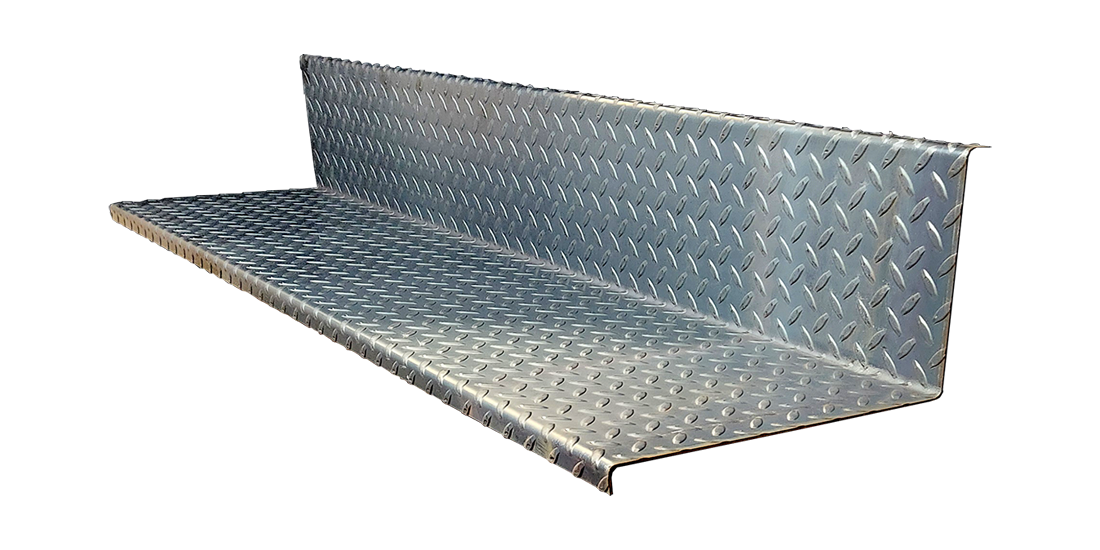

| Checker Diamond Plate Stair Pan | Model # | Description |

|---|---|---|

|

P-4A |

|

| Bar Grating Stair Tread | Model # | Description |

|---|---|---|

|

P-5A |

|

Colors

Overview

Metal Stair Treads and Stair Pans arrive standard unfinished and ready for welding. For additional costs and lead time, pre-galvanized sheet, hot-dipped galvanized or primer shop paint red is available.

Disclaimer: Actual color may vary between monitors and printers. Due to the manufacturing process, slight variations of color and texture will occur.

Images

Overview

View Metal Stair Tread images – showcasing product fabrication, assembly, features, and job site install.

Downloads Library

Overview

Download our current product resources. Contact us for questions.

- CAD Details

- Detail Binder

Disclaimer: Information contained here is for informational purposes only. The information is not to be construed as endorsements or recommendation for its use. While National Stair Products believes the information contained herein is accurate to the best of our knowledge, National Stair Products makes no warranty, express or implied with respect to the accuracy or readability of this information. The product data is offered for your consideration, investigation and verification. Your building code official must approve for your intended use.

Metal Stair Treads | Steel Stair Treads

Metal stair treads are an essential component of any staircase, providing both safety and functionality. They are the horizontal surfaces that you step on when climbing or descending stairs. Stair treads can be made from various materials such as metal, aluminum, carbon steel, or fiberglass. However, metal stair treads are highly preferred due to their durability and slip resistance.

The Importance of Steel Stair Treads

Stair treads play a crucial role in preventing accidents and providing traction. They offer a secure surface to walk on, reducing the risk of slips and falls, especially in high-traffic areas. Metal stair treads are known for their exceptional grip, thanks to serrations or diamond patterns on their surfaces. Additionally, metal stair treads can be galvanized to enhance their corrosion resistance and longevity.

What are Stair Treads?

Stair treads are the step-like surfaces that are positioned on a staircase. They are designed to provide stability, support, and safety when traversing stairs. Stair treads can come in various materials, including metal, aluminum, carbon steel, fiberglass, and stainless steel, allowing users to choose the most suitable option for their needs.

Benefits of Metal Stair Treads

Metal stair treads offer several advantages over other materials. They are highly durable, capable of withstanding heavy-duty usage without compromising their structural integrity. The serrated surface of metal treads provides excellent grip and slip resistance in both dry and wet conditions. Furthermore, metal treads can be fabricated and customized to meet specific specifications, ensuring a perfect fit for any staircase.

Types of Stair Treads

There are various types of metal stair treads available in the market. Aluminum stair treads are lightweight and corrosion-resistant, making them ideal for both interior and exterior stairs. Galvanized steel treads are coated with zinc to enhance their durability and rust resistance. Stainless steel treads are known for their superior strength and resistance to corrosion. Additionally, bar grating treads and diamond plate treads are popular options that offer anti-slip surfaces.

Choosing the Right Steel Treads

When selecting metal stair treads, there are several considerations to keep in mind. First, think about the material you want to use. Metal stair treads are available in a variety of options such as aluminum, carbon steel, and fiberglass. Each material has its own unique properties and advantages.

Next, consider the level of grip and slip resistance you require. Metal stair treads with serrated surfaces or diamond patterns offer excellent traction, making them ideal for areas prone to wet or slippery conditions.

Additionally, think about the specific requirements of your staircase. Are you looking for interior or exterior stair treads? Do you need heavy-duty treads that can withstand a high amount of foot traffic? Understanding your needs will help you choose the right metal stair treads for your project.

Advantages of Metal Stair Treads

Metal stair treads offer numerous advantages over other materials. First and foremost, they are incredibly durable and long-lasting. Metal treads are capable of withstanding heavy use without deteriorating, ensuring the safety and stability of your staircase for years to come.

Furthermore, the serrated surface of metal stair treads provides excellent grip, preventing slips and falls. This is especially important in areas where safety is a priority, such as industrial settings or outdoor staircases.

Another advantage of metal stair treads is their ability to be galvanized. Galvanization involves a protective zinc coating that enhances the corrosion resistance of the treads, making them even more durable and cost-effective in the long run.

Types of Metal Stair Treads

There is a wide range of metal stair treads available in the market to suit your specific requirements. Aluminum stair treads are popular due to their lightweight nature and corrosion resistance, making them suitable for both indoor and outdoor applications.

Galvanized steel treads, on the other hand, are coated with zinc to provide enhanced durability and rust resistance. These treads are an excellent choice for heavily trafficked areas or environments with high moisture levels.

If you're looking for superior strength and resistance to corrosion, stainless steel stair treads are a great option. They are known for their durability and are commonly used in applications where hygiene and longevity are critical.

Additionally, bar grating treads and diamond plate treads are two popular choices that offer slip resistant surfaces, providing excellent traction even in challenging conditions.

Installation of Metal Stair Treads

Preparation for Installation

Prior to installing metal stair treads, it is essential to properly prepare the staircase. Start by thoroughly cleaning the steps to remove any dirt, debris, or old adhesive. Make sure the surface is dry and free from any contaminants that could affect the adhesion of the treads.

Next, measure the dimensions of each step to ensure you have the correct size of metal treads for installation. Consider any nosings or overhangs that may require special attention.

Installation Process of Metal Stair Treads

The installation process of metal stair treads depends on the specific type and design of the treads. In general, the treads can be attached using mechanical fasteners, adhesives, or both.

If using mechanical fasteners, carefully position the treads on the steps and mark the locations for drilling. Pre-drill holes and then attach the treads using screws, bolts, or other appropriate fasteners.

For adhesive installation, apply a recommended adhesive to the back of each tread and press firmly onto the step, ensuring full contact and proper adhesion. Follow the manufacturer's instructions for the specific adhesive being used.

Ensuring Safety and Stability

After installing metal stair treads, it is crucial to ensure their safety and stability. Check that each tread is securely attached and does not wobble or shift when pressure is applied. Additionally, inspect the treads regularly for any signs of wear, damage, or loose fasteners.

Keep in mind that even with slip-resistant metal stair treads, it's important to clean and maintain them regularly. This helps to remove any debris or substances that could affect the tread's grip and overall performance.

By choosing the right metal stair treads and following proper installation procedures, you can enhance the safety and functionality of your staircase while adding a sleek, modern look. Whether it's for residential or commercial use, metal stair treads offer a durable and reliable solution for all your stairway needs.

Maintenance and Care of Metal Stair Treads

Metal stair treads require regular maintenance and care to ensure their longevity and performance. This includes cleaning, repairing, and conducting regular inspections. By following these steps, you can keep your metal stair treads in optimal condition for years to come.

Cleaning Metal Stair Treads

To maintain the cleanliness of your metal stair treads, it is important to regularly remove any dirt, debris, or substances that may accumulate on their surfaces. This can be done by sweeping or vacuuming the treads to remove loose particles. For more stubborn stains or grime, a mild detergent or cleaner can be used with a soft-bristle brush to scrub the surface gently.

When cleaning metal stair treads, it is important to avoid using abrasive materials or harsh chemicals that could damage the surface. Additionally, make sure to rinse the treads thoroughly after cleaning to remove any residue from the detergent or cleaner.

Repairing and Replacing Stair Treads

If you notice any signs of damage or wear on your metal stair treads, it is important to address them promptly to prevent further deterioration. Small cracks or chips can typically be repaired using an epoxy or adhesive specifically designed for metal surfaces.

In cases where the damage is more significant or affects the structural integrity of the treads, it may be necessary to replace the entire tread. This can be done by carefully removing the damaged tread and installing a new one in its place. It is important to ensure that the replacement tread is of the same material and size as the original for a seamless fit.

Regular Inspections and Maintenance

Regular inspections are essential to identify any potential issues with your metal stair treads and address them proactively. Inspect the treads for signs of corrosion, loose fasteners, or any other damage. Pay particular attention to areas where the treads connect to the staircase to ensure they are securely attached.

In addition to inspections, it is important to perform routine maintenance to keep the treads in optimal condition. This may include applying a protective coating or sealant to enhance their resistance to corrosion or reapplying for anti-slip properties if necessary. Following the manufacturer's guidelines for maintenance will help prolong the lifespan of your metal stair treads.